When choosing a third-party logistics (3PL) provider, the right specialization can make or break your business. A mismatch between your needs and the provider's capabilities can lead to delays, errors, and unhappy customers. Here's what you need to know upfront:

- Understand their strengths: Does the 3PL specialize in DTC (direct-to-consumer) fulfillment, B2B shipments, or specific product categories (like temperature-sensitive goods or hazardous materials)?

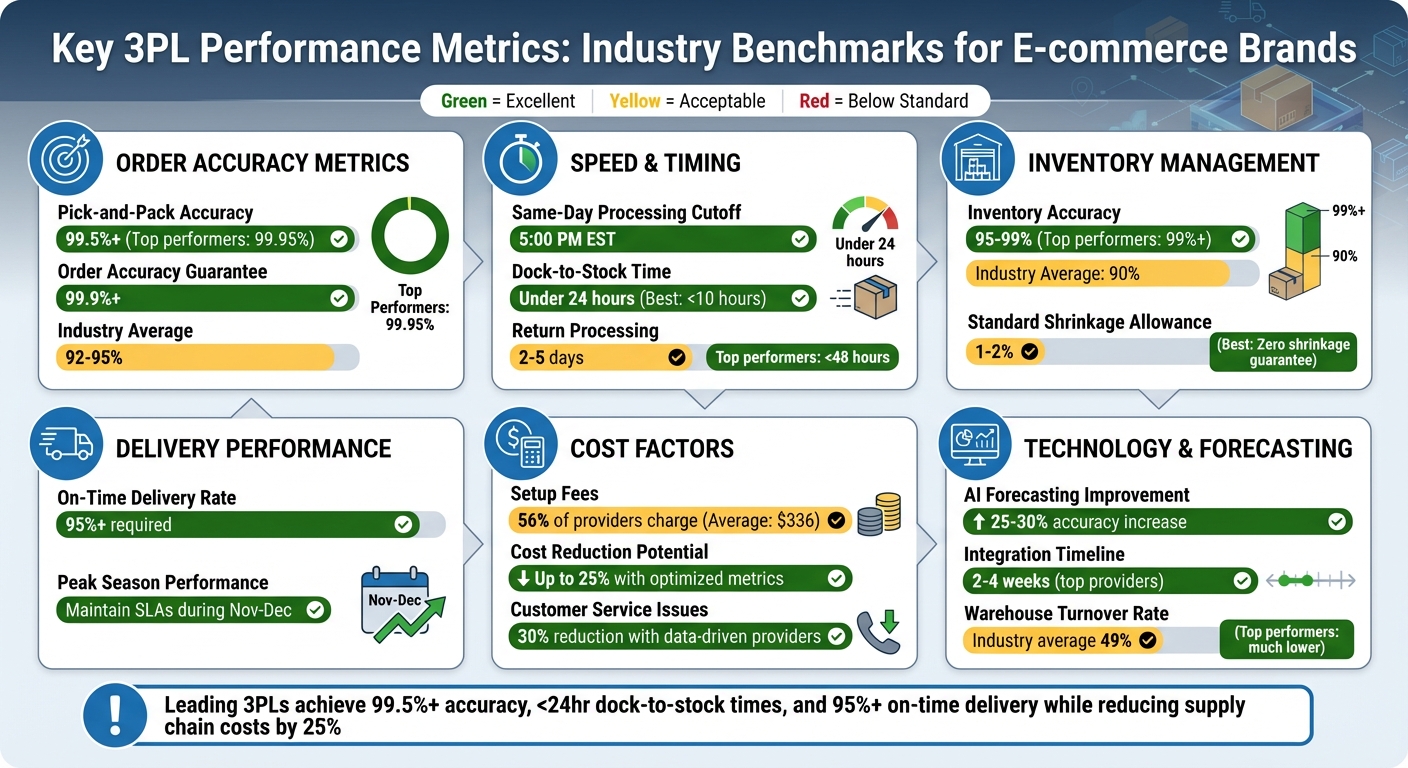

- Evaluate their accuracy and speed: Top providers boast pick-and-pack accuracy rates of 99.5%+ and dock-to-stock times under 24 hours.

- Check for scalability: Can they handle seasonal surges, like Black Friday, without delays? Do they use automation or multi-carrier platforms to avoid bottlenecks?

- Ask about value-added services: Look for options like kitting, branded packaging, or subscription box assembly to elevate your customer experience.

- Verify certifications for specialty products: If you sell regulated items like cosmetics or electronics, ensure they meet industry standards (e.g., FDA registration, HAZMAT certifications).

- Inspect their technology: Seamless integration with platforms like Shopify and real-time inventory tracking are non-negotiable for growing brands.

- Demand proof: Ask for case studies, metrics, and references to validate their claims.

The right 3PL should feel like a partner, not just a vendor. Use these questions to assess their capabilities and ensure they align with your goals.

Key 3PL Performance Metrics and Industry Benchmarks for E-commerce Fulfillment

Questions About DTC Fulfillment Capabilities

What DTC-specific processes do you handle?

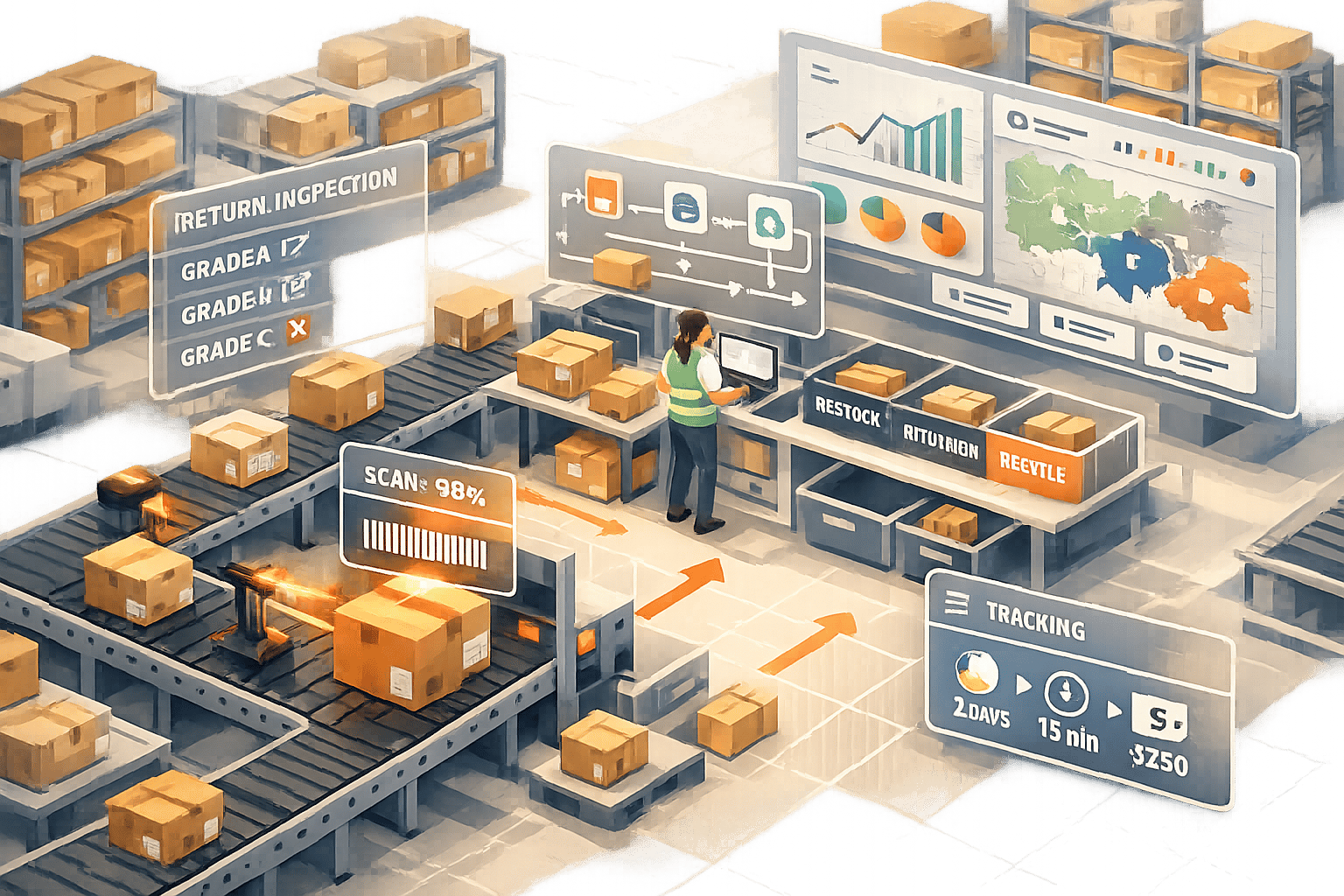

When evaluating 3PLs, dig into their scan-based fulfillment workflow. This involves barcode scanning at every step - receiving, picking, and packing - which helps reduce manual errors and keeps inventory records spot-on. For instance, Pit Viper saw a jump in order accuracy from 92% to 99.7% by upgrading their WMS controls.

Make sure they offer same-day processing, with many top providers adhering to a 5:00 PM EST cutoff. Also, check their dock-to-stock SLA, which refers to how quickly goods move from receiving to inventory. While average times range from 24–48 hours, some providers can do it in under 10 hours.

Ask about value-added services like kitting, branded packaging, and personalized inserts. Tuckernuck, for example, leveraged Ryder's automated systems to ship up to 20,000 orders in one day during a January sale - a task that previously took 14 days with their old 3PL. Look for features like an "Order Accuracy Guarantee" with penalties for errors and a "zero-shrinkage guarantee" instead of the usual 1–2% shrinkage allowance.

Lastly, find out how they handle demand spikes during busy seasons.

How do you manage peak season surges?

Ask about their strategies for maintaining consistent delivery times during peak periods. Leading providers often use automation, such as pouch sorter systems, which allow them to "flatten the peak" by pre-picking popular items during slower times and storing them for quick access when demand spikes.

You’ll also want to understand their labor scalability strategy. Strong providers can quickly ramp up their workforce to handle seasonal surges. Request specific SLAs for receiving and outbound fulfillment during November and December, and confirm their "last ship day" for guaranteed holiday delivery. Additionally, check if they use multi-carrier platforms to avoid delays and extra fees caused by relying on a single carrier during high-demand periods.

Next, explore their expertise in custom packaging.

What is your experience with custom packaging?

Ask for examples of branded packaging they’ve done for brands similar to yours. Confirm they can handle custom box selection, packing materials, and marketing inserts like thank-you notes, stickers, or discount codes. Verify if they allow you to set specific packing instructions and whether they assign dedicated account managers to oversee custom SOPs.

It’s also important to ask how they manage the inventory of packaging components to avoid running out of branded materials during crucial times. With 70% of consumers prioritizing eco-friendly brands, inquire about sustainable packaging options that align with your brand’s values. Lastly, check if they offer "white-label" or private-label fulfillment services to ensure your brand remains front and center.

Questions About Product Handling Capabilities

Do you handle specific product categories?

It's essential to check if the provider has experience managing your product type, whether it's fragile, oversized, or temperature-sensitive. These types of items often require specialized handling techniques.

Ask for case studies or examples that demonstrate their expertise with similar products. For fragile items, ensure they use protective packaging and specialized dunnage to minimize transit damage. If you're dealing with perishable goods, confirm they offer cold chain storage and adhere to FDA regulations, including tracking expiration dates. For heavy or bulky shipments, verify they have the right equipment, such as flatbeds or custom crates, to ensure your products are handled with care.

Top-performing operations often maintain a pick and pack accuracy rate of 99% or higher, with some exceeding 99.5%. For example, ShipBob reports an impressive 99.95% accuracy rate in order fulfillment, achieved through their warehouse management system (WMS) checks and balances.

Finally, explore their expertise in managing regulated or specialty items to ensure they meet industry standards.

What is your experience with regulated or specialty products?

For businesses selling items like cosmetics, food, supplements, or hazardous materials (e.g., batteries or aerosols), it's crucial to confirm the provider's certifications. Ask for proof of HAZMAT certification and FDA registration with compliance to cGMP standards. As Jay Group highlights:

"A HAZMAT Shipping Certified 3PL eliminates the guesswork from hazardous material transportation guidelines, including all special regulations and procedures when shipping by air, ground, rail and sea".

Check if they use FEFO (First Expired, First Out) or FIFO (First In, First Out) systems with barcoded tracking for lot numbers and expiration dates. Climate-controlled facilities are also vital to protect products from damage caused by extreme temperatures, moisture, or humidity. Additionally, confirm they stay informed about changing trade policies - such as the U.S. tariffs on Chinese imports, which reached 30% in 2025 and raised logistics costs by 10–15%.

After regulatory compliance, shift focus to how they handle high-value or sensitive items.

How do you manage high-value or sensitive goods?

Ask about their security protocols, including surveillance systems, access controls, and employee background checks. Verify that they use 100% scan-based fulfillment and conduct regular cycle counts - daily checks of specific product categories - to quickly identify and resolve discrepancies.

Negotiate a minimal shrinkage allowance, especially for high-value SKUs. Also, confirm they provide a real-time inventory dashboard for merchants. Ali Shahid, COO of Our Place, shares:

"The technology employed by ShipBob guarantees accurate deliveries to our customers. ShipBob's warehouse management system is equipped with numerous checks and balances, minimizing the possibility of incorrect items being shipped by warehouse associates".

Additionally, ensure they have strong cybersecurity measures in place to protect your data.

Questions About Technology and Scalability

What technology integrations do you support?

It's essential to confirm that the 3PL you choose integrates seamlessly with major e-commerce platforms like Shopify, WooCommerce, BigCommerce, Amazon, and TikTok Shop. Additionally, they should support open APIs and EDI for real-time data exchange - this is particularly important for DTC brands that require smooth system integration. If your business uses custom ERP systems, check if these integration options are compatible.

Their WMS (Warehouse Management System) and TMS (Transportation Management System) should offer real-time visibility into inventory levels, order statuses, and carrier performance. As Zvika Alon, COO of Edikted, shared:

"We are Shopify-based, so the technical integration with Ryder was seamless and straightforward."

Also, inquire about the onboarding timeline. Top-tier providers generally complete technology integration within two to four weeks. Before committing, ask for access to a sandbox environment or sample payloads to test compatibility with your tech stack. Be sure to clarify any hidden costs upfront. For instance, 56% of fulfillment providers charge account setup fees, which average $336, and some may also include extra charges for SKU management or IT integration. Having a reliable technology setup is crucial for managing rapid growth.

How do you handle scalability for growing brands?

A good 3PL should be prepared to support 10–20% monthly growth and handle your expected volume increases over the next 6–12 months. Request data on how they perform during peak times - such as Black Friday or Cyber Monday - to ensure they meet SLAs even during surges.

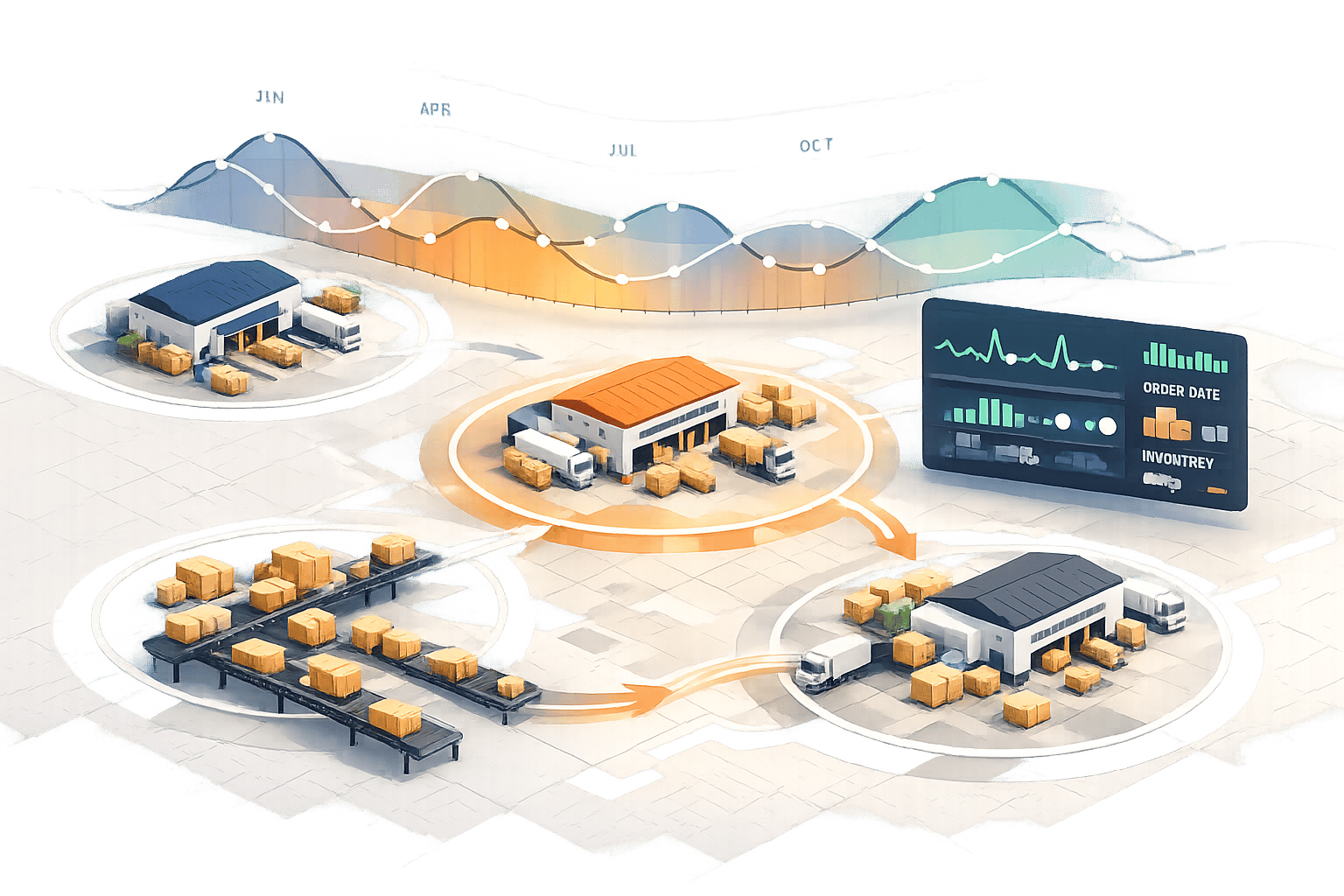

Providers with a multi-node fulfillment network have an edge. By distributing inventory across several warehouses, they can reduce last-mile delivery times and offer extra capacity for growth. Automation is another key factor - warehouse robotics, for example, are expected to help achieve 99.5% picking accuracy by 2025. A notable example is Ryder’s response during the early months of the pandemic in 2020, when they scaled SodaStream’s fulfillment ten-fold within two weeks to meet surging demand, then scaled back as things normalized.

Additionally, confirm that the provider works with multiple parcel carriers to avoid bottlenecks during high-volume periods. Be aware of any hidden scalability fees, such as peak season surcharges, seasonal labor markups, or penalties for not meeting minimum order quantities. A scalable system should also offer clear performance tracking to ensure transparency.

What tools do you provide for tracking performance?

Evaluate their dashboard to ensure it provides real-time updates on inventory levels, order statuses, and SLA performance. Real-time updates are critical to avoiding issues like overselling. Top-performing 3PLs typically achieve 95% or higher inventory accuracy, surpassing the industry average of 90%.

Look for systems that automatically flag issues - like delayed shipments or stuck orders - so they can be resolved quickly. Many advanced providers now use AI-driven predictive analytics, which can improve demand forecasting accuracy by 25% to 30%. Some also employ IoT devices and blockchain technology to offer end-to-end supply chain traceability.

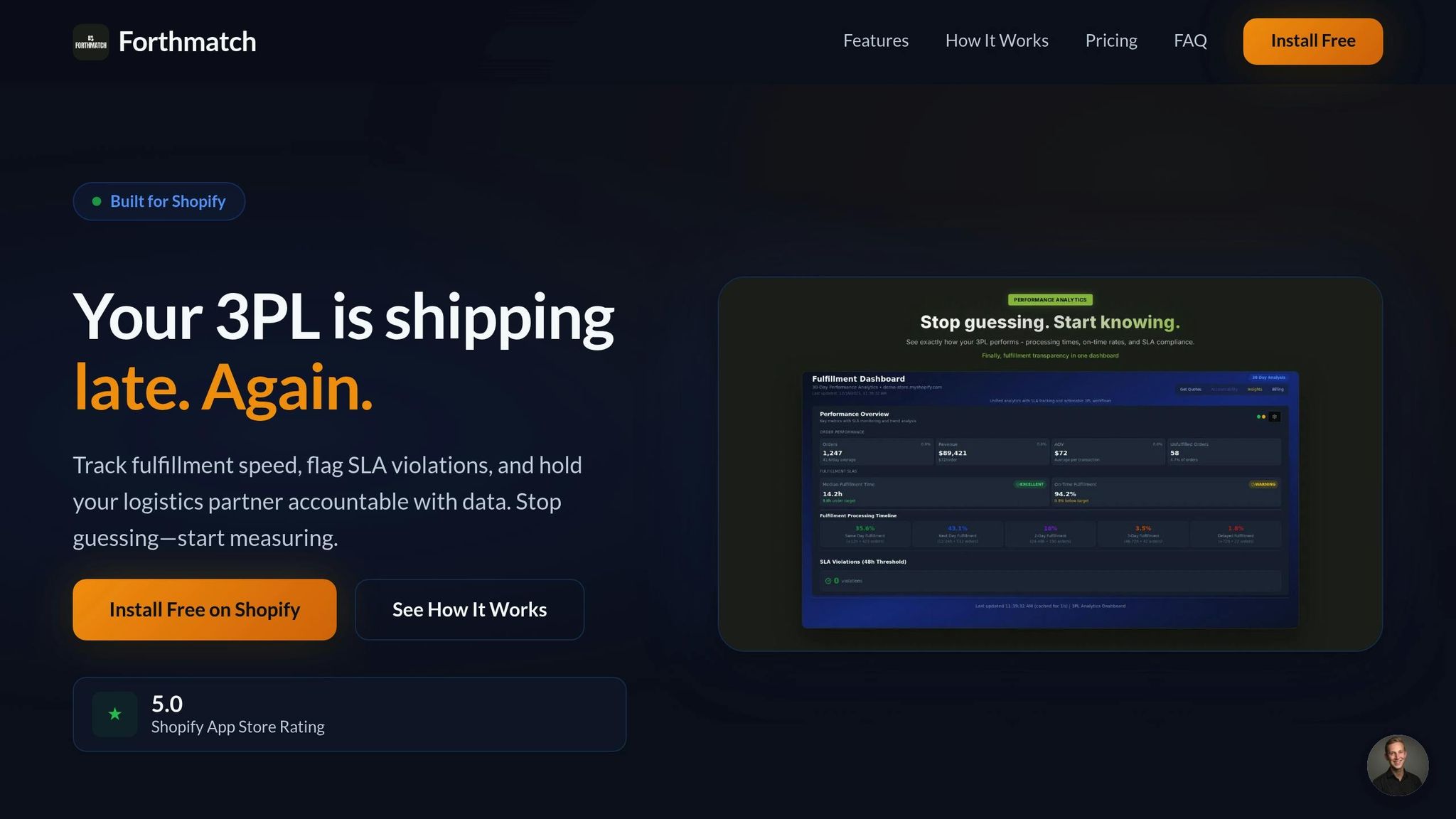

Request a demo to assess the system’s usability and the depth of its data. Ensure it includes automated alerts for order updates, low inventory thresholds, and tracking details. Tools like Forthmatch, which integrates with Shopify, can help monitor fulfillment speeds, flag SLA violations, and generate performance reports. These insights are invaluable for maintaining smooth operations.

Questions About Performance Metrics and Proof

Can you share case studies or references?

When evaluating a 3PL, ask for examples from brands in your specific category. For instance, if you're in the cosmetics industry, the provider should demonstrate how they've managed temperature-sensitive products or fragile glass packaging for similar clients. Additionally, request direct customer references from businesses of comparable size and volume. This allows you to hear firsthand about the provider's responsiveness and reliability, reinforcing their operational reliability and performance claims.

Another key indicator to look for is whether the provider has a Continuous Improvement Program (CIP) or holds an ISO-9001 certification. These certifications aren't just formalities - they show the provider's commitment to preventing errors and refining processes over time. As Kanban Logistics puts it:

"A 3PL's continuous improvement program is much more than a collection of policies and procedures – it is proof that the 3PL is truly committed to the quality of its services."

Also, check their staff turnover rates. While the warehouse industry averages a 49% annual turnover rate, top-performing providers maintain much lower rates. A stable team often correlates with higher pick-and-pack accuracy, frequently exceeding 99.5%. Ask for turnover data from the past 12 months to get a sense of team stability and its potential impact on service quality.

What are your key performance metrics?

Ask for specific numbers on order accuracy, on-time delivery, and inventory accuracy. Leading 3PLs typically achieve order accuracy rates above 99.9%, on-time delivery rates of 95% or higher, and inventory accuracy levels ranging from 95% to 99%. If their metrics fall below these benchmarks, it may be a red flag.

Another critical metric to inquire about is dock-to-stock time - the time it takes to process inbound shipments. The best providers can complete this within 24 hours. A faster dock-to-stock process means your inventory becomes available for sale sooner, which is crucial for maintaining cash flow and avoiding stockouts.

Additionally, clarify how the provider defines "on-time" delivery. Some measure it from the moment a shipping label is printed, while others use carrier acceptance scans as the standard. The latter is more accurate since shipping labels can sit idle for hours before pickup. Providers that actively track and optimize these metrics often achieve up to 25% lower supply chain costs and see a 30% reduction in customer service issues.

How do you use data to prove your capabilities?

Data-driven proof is essential. For example, providers should use root cause analysis (RCA) to address discrepancies. Tony Runyan, Chief Client Officer at Red Stag Fulfillment, explains their methodology:

"To minimize inventory shrinkage... we regularly perform cycle counts in inventory locations that are low, communicate any issues to customers immediately, and conduct a thorough root cause analysis whenever recorded stock levels do not match the reality."

Request 12 months of historical performance data to assess how they handle peak seasons like Black Friday and Cyber Monday. This provides insight into their ability to maintain consistency under pressure. Providers using AI-driven predictive analytics can also improve demand forecasting accuracy by 25–30% for the 2024–2025 period.

If returns processing is a priority, ask how they measure return processing time. While the industry standard is 2–5 days, top-performing 3PLs can complete this in under 48 hours. Faster processing means quicker cash flow and inventory reintegration, which are critical for maintaining operational efficiency.

sbb-itb-eb0f906

How To Choose The Right 3PL For Your eCommerce Business

Using Forthmatch to Evaluate 3PL Specializations

Forthmatch provides a streamlined way to evaluate third-party logistics (3PL) providers, aligning its tools with real-time performance and scalability metrics to simplify your decision-making process.

Monitor SLA Performance with Real-Time Data

Forthmatch helps you keep a close eye on fulfillment metrics by analyzing Shopify order timestamps - tracking the time between "Order Created" and "Fulfillment." This allows you to set specific SLA benchmarks, like shipping 98% of orders the same day if received by noon. If there's a breach, the platform sends automatic alerts. For example, you might discover that "15% of orders missed the 24-hour SLA last week", converting operational uncertainty into actionable data.

These detailed insights help you identify whether issues originate from your 3PL's internal processes or external carrier delays. With industry benchmarks like 99.5%+ pick-and-pack accuracy and 98%+ same-day shipping rates, Forthmatch enables you to measure your provider's performance against these standards. This level of monitoring lays the groundwork for informed reviews and comparisons.

Run Data-Backed Performance Reviews

Forthmatch's Accountability Session feature tracks performance over a 2–4 week period, establishing a baseline and delivering a detailed PDF report comparing "before and after" metrics. This is particularly useful for quarterly business reviews or renegotiating contracts, offering concrete data to validate improvements.

The platform also logs alerts sent to your account manager and tracks their responsiveness. With leading providers typically committing to email response times under 3 hours, this documentation ensures accountability if your 3PL consistently delays replies - especially when responses take over 24 hours. Such records are invaluable during contract renewals, helping you decide whether to stick with or switch providers.

Use RFP Tools for Provider Comparisons

If your current 3PL isn't meeting your needs, Forthmatch's RFP Quote Request tool simplifies the process of sourcing new providers. By using your order data, the tool automates proposals and connects you with vetted providers across DTC, B2B, and FBA channels. This allows you to compare quotes side-by-side - not just by price but also by strategic fit.

The tool ensures transparency by highlighting hidden costs. For instance, 56% of fulfillment providers charge setup fees averaging $336. With Forthmatch, you can evaluate total landed costs, including storage, pick-pack, and shipping fees, across multiple candidates. This approach integrates seamlessly with performance metrics, ensuring a consistent and data-focused evaluation process.

"Selecting a 3PL may seem like a daunting task, but it should be a celebration of the growth and success of your business. If you prioritize your needs such as cost, quality, and speed, you're sure to select a long-term partner that operates as a strong extension of your brand".

Conclusion: Choosing the Right 3PL for Your Needs

Selecting the right 3PL provider comes down to focusing on key capabilities and verifying their performance with hard data. The questions outlined in this guide - covering areas like DTC capabilities, product handling expertise, technology integration, and measurable metrics - help cut through vague promises and identify providers that align with your brand's specific needs. Look for a 3PL that delivers a pick-and-pack accuracy of 99.5% or higher and has the ability to scale seamlessly during peak seasons, acting as a true extension of your operations.

Before making a final decision, consider piloting a subset of SKUs, reviewing historical performance data, and conducting an onsite evaluation to assess security measures and operational controls. These steps help turn promises into tangible proof.

Forthmatch simplifies this process by turning subjective concerns into measurable insights. With tools like real-time SLA monitoring, automated alerts, and detailed performance reviews, the platform ensures that providers remain accountable throughout the partnership - not just during the sales pitch. The RFP Quote Request tool also helps you compare total landed costs, making it easier to spot hidden fees that can lead to 10% to 30% cost overruns.

This data-driven approach not only makes the evaluation process smoother but also highlights the strategic advantages of partnering with a capable 3PL.

"The 3PL model has so many benefits over owning and operating. You can convert what was historically a fixed cost to a variable one, and focus on what you're good at, which is growing your brand." – Casey Isaac, Senior Director of Strategic Sales and Partnerships, Flowspace

Ultimately, choosing a 3PL is about finding a partner that aligns with your growth objectives, scales with your brand, and consistently delivers on customer expectations. By using these targeted questions and leveraging data-backed tools, you can build a solid foundation for your fulfillment strategy.

FAQs

What factors should I consider when selecting a 3PL for my DTC business?

When choosing a 3PL for your direct-to-consumer (DTC) business, it's crucial to assess how well they can handle your unique requirements. Key considerations include their ability to manage your order volume, adapt to growth, and provide support during peak seasons. Make sure to explore their inventory management processes, geographic reach, and strategies for positioning inventory to guarantee quick and cost-efficient deliveries.

It's also worth examining their technology capabilities - look for features like real-time tracking and seamless integration with your e-commerce platform. Don't forget to evaluate their service level agreements (SLAs) to ensure they meet your performance standards. Taking a data-focused approach to analyze their past performance can give you the confidence to make the right choice.

What strategies do 3PL providers use to manage seasonal demand spikes?

To handle seasonal demand spikes well, a 3PL provider needs to prioritize planning ahead and staying adaptable. This involves studying past sales data to predict demand, strategically distributing inventory across multiple warehouses, and scaling up staffing and resources to meet peak-season needs.

Taking these steps early can help avoid delays, prevent stockouts, and keep operations running smoothly. Additionally, maintaining clear communication with clients and using real-time tools to monitor fulfillment performance are essential for managing seasonal changes effectively.

What certifications should a 3PL have to handle regulated products?

When working with regulated products such as pharmaceuticals, medical devices, food, supplements, or cosmetics, it's crucial to confirm that your 3PL provider has the necessary certifications to comply with FDA regulations. Two key ones to check for are Good Manufacturing Practices (GMP) and certifications specific to shipping and handling validation.

These certifications ensure the 3PL can adhere to the rigorous safety, quality, and operational standards required in regulated industries. This helps protect both compliance and the integrity of your products.