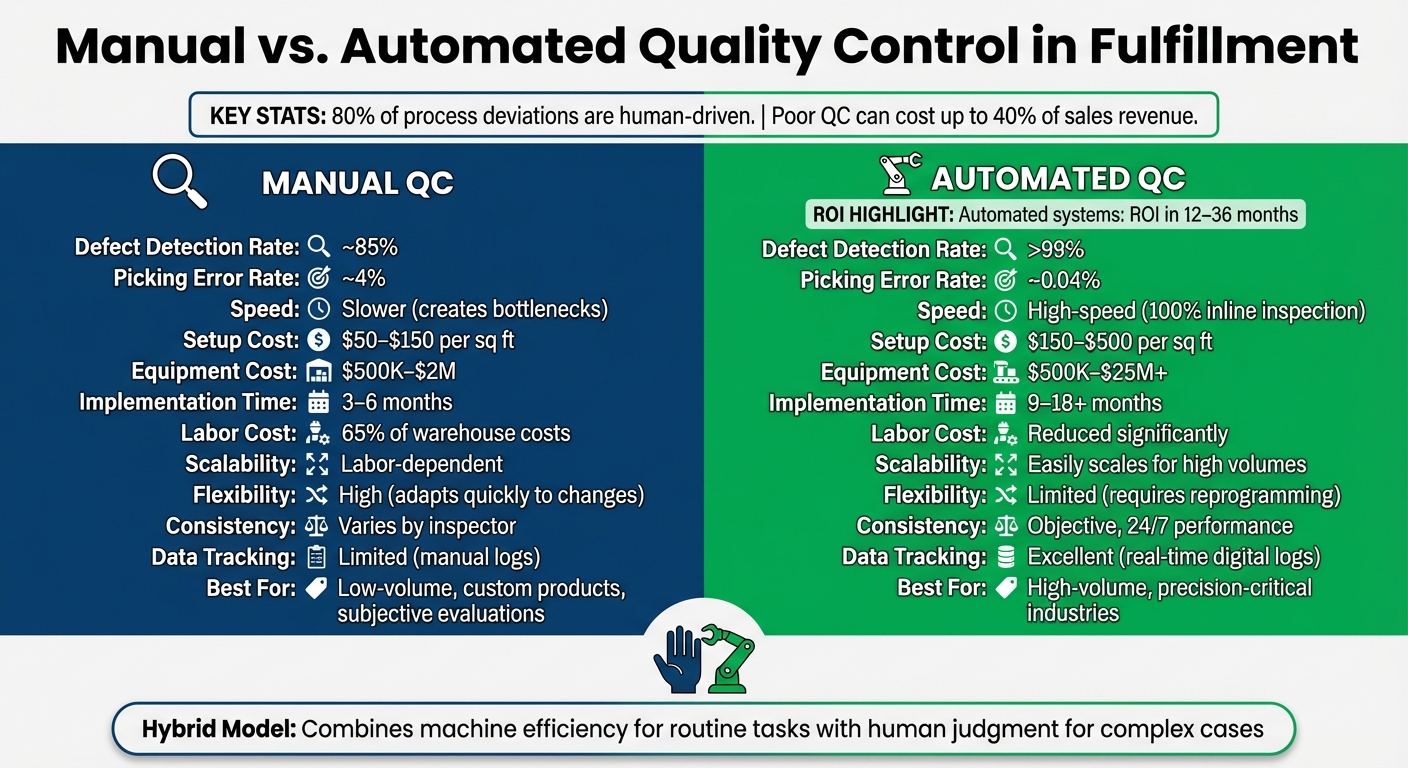

Manual vs. Automated Quality Control boils down to balancing flexibility with precision. Manual methods rely on human judgment for inspections, making them suitable for small-scale, custom, or aesthetic-focused products. In contrast, automated systems use technologies like AI and robotics to deliver unmatched accuracy, speed, and scalability for high-volume operations.

Key Takeaways:

-

Manual Quality Control:

- Detects ~85% of defects.

- Lower upfront fulfillment costs ($50–Lower upfront costs ($50–$150/sq ft).50/sq ft).

- Labor-intensive (65% of warehouse costs).

- Ideal for low-volume, variable, or subjective evaluations.

- Prone to fatigue, inconsistency, and slower throughput.

-

Automated Quality Control:

- Detects over 99% of defects.

- Higher upfront costs ($150–$500/sq ft; $500K–$25M for equipment).

- Reduces labor reliance and long-term costs.

- Best for high-volume, repetitive, and precision-demanding tasks.

- Faces challenges with irregular products and high initial investment.

Quick Comparison:

| Metric | Manual QC | Automated QC |

|---|---|---|

| Defect Detection | ~85% | >99% |

| Picking Error Rate | ~4% | ~0.04% |

| Speed | Slower | High-speed |

| Cost (Setup) | $50–$150/sq ft | $150–$500/sq ft |

| Scalability | Labor-dependent | Easily scales |

| Flexibility | High for changes | Limited for changes |

Choosing the Right Approach:

- Use manual QC for small-batch, custom, or subjective needs.

- Opt for automation in high-volume, precision-critical industries like pharmaceuticals or electronics.

- A hybrid model combines both: machines handle routine tasks, while humans address complex cases.

Bottom Line: Your decision should align with your production volume, defect tolerance, and budget. Combining both methods often provides the best balance of efficiency and adaptability.

Manual vs Automated Quality Control: Key Metrics Comparison

Manual Quality Control: How It Works and What to Expect

The Manual Quality Control Process

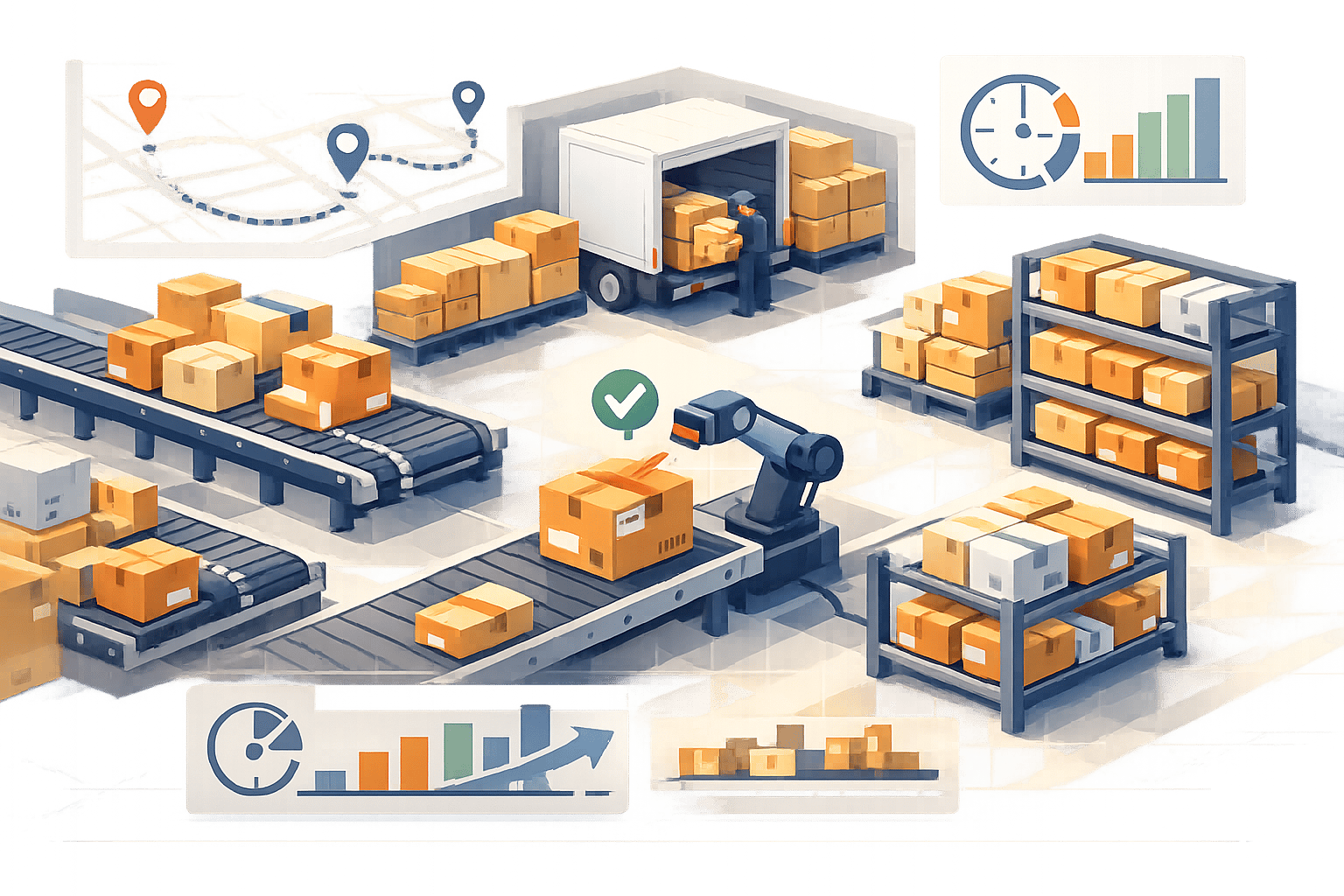

Manual quality control involves human inspectors working through a series of checkpoints to ensure products meet quality standards. The process typically starts with receiving inspection, where workers count incoming inventory, check for visible damage or defects, and log items into the system. Often, sampling is used to evaluate a portion of each batch against established standards.

As items move through the fulfillment process, inspectors verify physical products against packing slips and order details, confirming that SKUs, colors, and sizes align with specifications. They rely on their senses to spot issues like scratches, stains, or dents and assess aesthetic features such as texture and finish. Tools like calipers and gauges help confirm dimensions and tolerances. During order verification, packers double-check items to ensure accuracy before sealing packages. For returned goods, workers inspect and test items to decide whether they can be resold, repaired, or recycled. All findings are manually recorded in reports or databases for future reference and quality analysis.

These checkpoints highlight the strengths and limitations of manual quality control, offering a closer look at its role in maintaining product standards.

Advantages of Manual Quality Control

One of the standout benefits of manual quality control is its adaptability. Human inspectors can handle non-standard or irregular items without requiring reprogramming or specialized equipment. This makes it particularly useful for small-batch production, prototypes, or products where subjective judgment is key - such as evaluating the feel of textiles or the visual appeal of furniture finishes.

"Manual inspection is highly flexible and ideal for custom, low-volume, or aesthetic products requiring human intuition and subjective evaluation." - Hammer-IMS

Another advantage is the lower upfront investment compared to automation. Setting up a manual warehouse costs significantly less, with basic equipment ranging from $500,000 to $2 million. Implementation is also faster, taking 3 to 6 months versus the 9 to 18+ months often needed for automated systems. A single inspector can perform multiple tasks - visual checks, tactile assessments, and simple functional tests - within one workflow, something that machines struggle to replicate. While manual QC offers flexibility, its challenges become more apparent when compared to automated solutions. These challenges often lead to 3PL conflicts regarding accuracy and cost.

Drawbacks of Manual Quality Control

Despite its advantages, manual quality control has notable drawbacks that can affect efficiency. Subjectivity and inconsistency are among the biggest challenges. Quality assessments can vary between inspectors - or even for the same inspector over time - due to differences in judgment, skills, and fatigue from repetitive tasks. Human-driven processes account for 80% of process deviations in warehousing.

Speed is another limitation. Manual inspection is slower than automated methods, which can create bottlenecks and reduce overall throughput. Additionally, labor costs are a significant factor, making up 65% of total warehouse fulfillment expenses in manual operations. Scaling up during busy seasons requires hiring and training temporary workers, a process that is both costly and time-intensive.

Data collection also presents challenges. Manually logged information is often incomplete or inconsistent, complicating efforts to perform root-cause analysis or track quality trends over time. Without structured data, it becomes harder to identify recurring issues and implement lasting improvements.

sbb-itb-eb0f906

Automated Quality Control: How It Works and What to Expect

The Automated Quality Control Process

Automated quality control tackles the limitations of manual inspection by integrating sensors, cameras, and AI throughout the fulfillment process - from receiving inventory to shipping orders. This approach ensures 100% inline inspection, meaning every unit is checked at production line speeds without human input.

The system relies on a mix of technologies. Barcode scanners and RFID systems handle real-time tracking and inventory updates. Machine vision cameras, powered by AI, detect issues like scratches, dents, missing parts, incorrect assembly, and labeling errors. Advanced sensors, including laser tools, 3D profilers, and thermal detectors, are used to spot dimensional inaccuracies and hidden flaws.

Robotics also plays a key role. Autonomous Mobile Robots (AMRs), Automated Guided Vehicles (AGVs), and robotic picking arms streamline product movement through inspection stations. Meanwhile, Automated Storage and Retrieval Systems (AS/RS) and sorting conveyors manage inventory flow efficiently. All inspection data is logged digitally in real time, syncing with Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) platforms. This integration supports analytics, traceability, and root-cause analysis, improving both accuracy and workflow efficiency.

Advantages of Automated Quality Control

Automated systems outperform manual methods in several ways, with accuracy and consistency being the most notable. Unlike humans, machines don’t experience fatigue or distractions, ensuring objective and reliable results around the clock. Detection accuracy rates typically range between 99% and 99.9%, while picking error rates can drop to just 0.04%.

Speed is another major benefit. Automated systems keep up with production line speeds, making them ideal for high-volume operations without causing delays. A great example is Kookaburra Educational Resources, which implemented automated sorting systems and saw impressive results: labor needs dropped by 65%, the night shift was eliminated, and daily output increased from 300 to over 700 student supply packs. Their sorting rates reached 2,400 items per hour.

"Automated quality control lets you inspect products at high speed and with great accuracy. You can detect problems early and prevent large-scale defects." – FanRuan

Cost savings over time are another key advantage. Labor often accounts for 65% of total warehouse costs in manual setups. Automated systems reduce these costs while also minimizing expenses related to defects, scrap, and recalls - cutting defect-related costs by up to 30%. Businesses typically see a return on investment within 12 to 36 months.

Drawbacks of Automated Quality Control

Despite its benefits, automated quality control comes with challenges. The biggest hurdle is the high upfront investment. Setting up an automated warehouse can cost $150 to $500 per square foot, compared to $50 to $150 for manual operations. Equipment expenses range from $500,000 to over $25 million, and advanced software can cost between $250,000 and over $1 million. Implementation timelines are longer too, taking 9 to 18+ months versus 3 to 6 months for manual systems.

Technical complexity is another issue. These systems require specialized expertise for setup, calibration, and maintenance. Problems like sensor drift or outdated software can lead to errors, such as false positives (rejecting good items) or false negatives (missing defects). Environmental factors, such as poor lighting, vibrations, dust, or temperature changes, can also interfere with performance.

Flexibility is a concern as well. Automated systems often struggle with irregular or highly variable products, requiring significant reprogramming or AI retraining when product lines change. They may also fall short in assessing aesthetic details like surface texture or subtle color differences, where human judgment excels. Additionally, introducing automation can lead to workforce resistance, as employees may worry about job displacement or require extensive retraining to adapt to new technologies.

Manual vs. Automated: A Direct Comparison

Performance Metrics Compared

When comparing manual and automated quality control, performance metrics reveal stark contrasts. Manual inspections catch about 85% of defects, leaving 15% undetected. On the other hand, AI-driven automated systems boast detection rates exceeding 99%. This gap stems from human limitations like fatigue, stress, and subjective judgment - issues machines don't face when running continuously.

The differences are equally striking in speed and accuracy, which directly impacts how 3PLs improve perfect order rates. Manual order picking has an error rate of roughly 4%, whereas automated systems reduce this to just 0.04% - a 100-fold improvement. Moreover, automated systems maintain their performance even as volumes increase, while manual processes often struggle to keep pace.

| Metric | Manual Quality Control | Automated Quality Control |

|---|---|---|

| Defect Detection | ~85% | >99% |

| Picking Error Rate | ~4% | ~0.04% |

| Speed | Slower; creates bottlenecks | Extremely fast; 100% inline inspection |

| Consistency | Varies by inspector and time | Objective; repeatable 24/7 |

| Scalability | Requires proportional labor increase | Easily scales for high volumes |

| Initial Investment | Low | High ($500K–$25M+ equipment) |

| Long-term Cost | High ongoing labor (65% of warehouse costs) | Lower per-unit cost; ROI in 1–3 years |

| Flexibility | High; adapts quickly to changes | Lower; requires reprogramming |

| Data Tracking | Limited; manual logs | Excellent; real-time digital logs |

Cost structures also differ significantly. Manual systems rely heavily on labor, which accounts for 65% of warehouse expenses. These costs rise as volume increases. Automated systems, though initially expensive - ranging from $150 to $500 per square foot compared to $50 to $150 for manual setups - offer lower per-unit costs over time. This makes their return on investment (ROI) particularly appealing, often achieved within one to three years. Additionally, poor quality control can drain up to 40% of a manufacturer's sales revenue through rework, recalls, or liability claims, making the precision of automated systems a financial necessity.

These performance metrics can guide businesses in selecting the most suitable quality control method for their operations. Choosing the right approach is critical to meet marketplace fulfillment SLA requirements and avoid costly penalties.

When to Use Each Approach

The choice between manual and automated quality control depends on factors like production volume and product variability. Manual quality control shines in low-volume operations, custom products, and prototypes where subjective judgment is essential. For example, inspecting handcrafted furniture, assessing fabric textures, or evaluating subtle color differences often requires the nuanced expertise of human inspectors. Manual methods are also well-suited to environments where product lines frequently change, as humans can adapt quickly without the need for reprogramming.

On the flip side, automated quality control is ideal for high-volume production with consistent product specifications. If you're processing thousands of identical items daily, verifying precise dimensions, or conducting 100% inline inspections without slowing production, automation is the clear winner. Industries like pharmaceuticals and electronics particularly benefit from automated systems, which can detect microscopic flaws that human eyes might miss. A 2025 survey revealed that 49% of manufacturers plan to adopt AI within two years, with 45% focusing on defect detection.

Many companies find success by combining both methods in a hybrid "Human-in-the-Loop" model. Here, automated systems handle routine inspections at high speed, while ambiguous cases are escalated to human inspectors for final evaluation.

How to Choose the Right Quality Control Method

What to Consider Before Deciding

Deciding between manual and automated quality control comes down to understanding your specific operational needs. One of the biggest factors is production volume - if you're handling high volumes, automation often makes more sense because manual processes can't keep up with the speed required.

The type of defects is another key consideration. Automated systems are great for objective checks like measuring dimensions, verifying weights, or scanning barcodes. But when it comes to subjective assessments - like judging aesthetic appeal, texture, or the "feel" of a product - manual inspection is still essential. For example, a furniture manufacturer inspecting wood grain patterns needs human expertise, while a pharmaceutical company counting pills benefits more from automation.

Budget is also a major factor, and it's not just about upfront costs. Manual systems are cheaper to set up, with costs ranging from $50 to $150 per square foot, but they come with high ongoing labor expenses - labor typically accounts for 65% of total warehouse fulfillment costs. Automated systems, on the other hand, cost between $150 and $500 per square foot to install but lower per-unit costs over time and can deliver a return on investment within one to three years. Keep in mind that manual systems can be up and running in three to six months, while automated systems may take nine to 18 months or longer.

Accuracy requirements are critical, especially in industries where errors can have serious consequences. Manual inspections detect about 85% of defects due to limitations like fatigue and bias. Automated systems, however, can catch over 99% of defects, making them indispensable for sectors like pharmaceuticals or electronics where precision is non-negotiable. Mistakes can be costly - each picking error can cost between $20 and $60, and poor quality control can eat up to 40% of sales revenue due to rework and recalls.

Finally, consider integration and data needs. Automated systems provide structured data - real-time dashboards, heat maps, and trend graphs - that make it easier to identify patterns and improve processes. Manual logging often lacks consistency, making it harder to analyze and act on. If you're working with third-party logistics (3PL) providers on platforms like Shopify, having access to integrated data becomes even more important to monitor fulfillment performance across your supply chain.

Using Both Methods Together

For many businesses, combining manual and automated quality control works better than relying on just one method. The "Human-in-the-Loop" (HITL) hybrid model takes advantage of both: automated systems handle repetitive, high-volume inspections quickly, while humans step in for exceptions or situations requiring judgment.

This approach is especially effective in complex environments. Automated systems can flag ambiguous cases - products that fall outside normal parameters but aren't clearly defective - for human review. This not only boosts accuracy but also provides feedback that helps improve AI systems over time. In the automotive industry, for example, pairing machine vision with human oversight has improved defect detection by 30% and halved inspection times.

The first step to implementing this hybrid approach is standardizing your Standard Operating Procedures (SOPs). Clear documentation of manual processes creates a baseline for programming automated systems. This ensures consistency across shifts and locations, whether you're using manual checks, automation, or both. Start with scalable automation solutions that can be phased in and adjusted as your business grows.

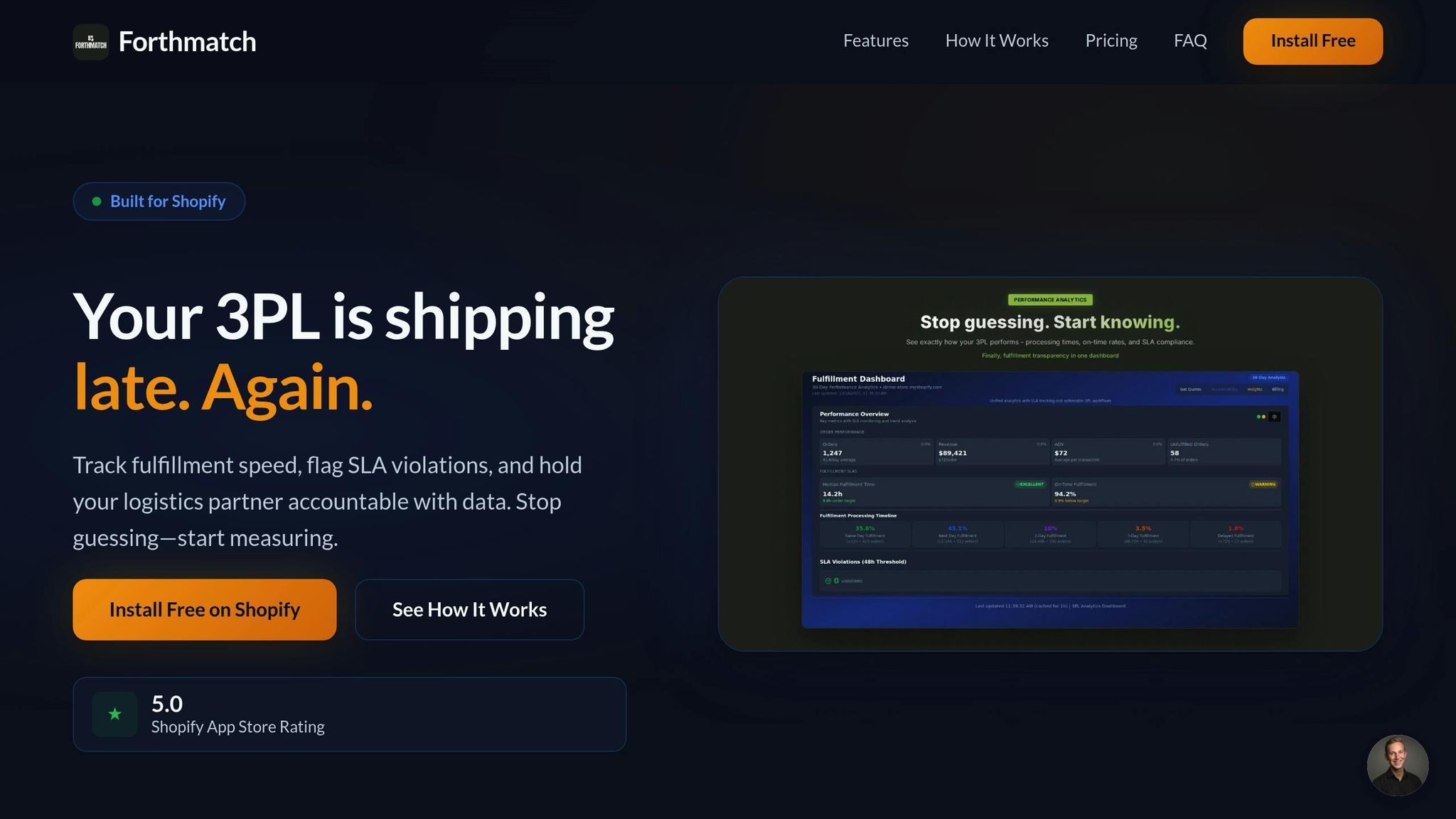

How Forthmatch Improves Fulfillment Oversight

Even with a solid quality control strategy, keeping tabs on your 3PL's performance is essential to maintain high standards. Forthmatch offers a data-driven way to monitor fulfillment operations, regardless of whether your partner uses manual or automated inspections. The app tracks order processing times, flags SLA violations, and categorizes delays - turning vague complaints like "shipping feels slow" into actionable data such as "15% of orders missed the 24-hour SLA."

This level of visibility is crucial since human-driven processes account for 80% of warehousing deviations. Forthmatch's automated tracking catches issues that manual oversight might miss, creating a detailed record of your 3PL's performance. You can even send one-click email alerts to address delayed orders. For $19/month (with a 14-day free trial), the Performance Insights plan provides extended analytics, carrier breakdowns, and trend reports to help pinpoint whether problems stem from your 3PL’s processes or specific carriers.

If you're preparing for quarterly business reviews or renegotiating contracts, the Accountability Session add-on ($89 per session) offers a focused performance review. It tracks a two- to four-week period, generating a PDF report that compares "before and after" stats - perfect for productive discussions with logistics partners. And if your current 3PL isn't improving, the RFP Quote Request feature ($44 per request) uses your order data to help you evaluate alternative providers by asking the right questions, ensuring you're getting the best value for your money.

Automated Quality Control: Advancing Quality Control through Automation | Interview and Demo

Conclusion

Each quality control method comes with its own strengths and trade-offs, making the choice highly dependent on your specific fulfillment needs. Manual inspection allows for flexibility and subjective decision-making, while automated systems excel at delivering consistent and highly accurate results. However, manual methods may overlook certain defects, whereas automation is designed to catch nearly all of them.

For many direct-to-consumer (DTC) brands, a hybrid approach often proves to be the most effective. Automation can handle repetitive, objective tasks with precision, while human oversight steps in for more complex scenarios that require critical thinking and nuanced judgment. This "Human-in-the-Loop" model combines the strengths of both systems, balancing the speed and reliability of machines with the adaptability and intuition of human inspectors. Instead of chasing the latest technology trends, it’s important to align your quality control strategy with your production volume, product complexity, and accuracy goals. This is especially crucial when managing third-party logistics, where maintaining consistent quality across the supply chain can be a challenge.

The stakes are high: poor quality control can result in rework, recalls, and brand damage, potentially costing up to 40% of sales revenue. Whether you lean on manual processes, automated systems, or a mix of both, the key is maintaining full visibility across your fulfillment network. This is particularly critical when working with third-party logistics providers, where ensuring uniform quality standards can make or break your brand's reputation.

Successful brands don’t just stop at implementing quality control - they also leverage data-driven insights for continuous improvement. Beyond catching defects, automated systems can generate valuable analytics to uncover patterns, predict equipment failures, and optimize the entire supply chain. By combining robust quality control practices with ongoing performance monitoring, you can establish accountability at every stage of the fulfillment process and ensure long-term success.

FAQs

What should I consider when deciding between manual and automated quality control?

When weighing manual vs. automated quality control (QC), it’s essential to factor in product complexity and volume. Manual QC works well for smaller batches, one-of-a-kind items, or products with intricate designs where a human eye can catch subtle imperfections. On the flip side, automated QC shines in high-volume, repetitive tasks, delivering speed, accuracy, and advanced detection capabilities.

Cost and scalability play a major role too. While manual QC might seem more affordable upfront, it can be labor-intensive and prone to human error. Automated systems, though requiring a larger initial investment, often save on labor costs over time and can handle increased production demands as your business grows.

Lastly, consider how much human judgment is needed. Manual QC is ideal for subjective evaluations or aesthetic decisions, whereas automated systems are perfect for environments that demand consistency, traceability, and real-time insights. Weighing these factors carefully will guide you toward the right QC solution for your needs.

What are the benefits of combining manual and automated quality control?

Combining manual and automated quality control creates a balanced approach that boosts accuracy, efficiency, and adaptability in your fulfillment operations. Manual checks are perfect for spotting complex or aesthetic issues that need human expertise, while automated systems shine when it comes to high-volume, repetitive tasks that demand speed and precision.

This hybrid strategy lets you automate routine inspections, cutting labor costs and speeding up processes, while reserving manual reviews for critical or specialized evaluations. The result? Improved quality assurance, fewer errors, and a system that adjusts effortlessly to evolving production demands. Tools like Forthmatch play a key role by tracking SLA compliance, flagging delays, and offering actionable insights to fine-tune your fulfillment workflows.

What are the long-term costs and benefits of automated quality control?

Automated quality control can lead to major savings over time by cutting down on expenses associated with manual labor - like wages, training, and human error. By automating processes, businesses can reduce defective products, eliminate costly rework, and avoid recalls, all while maintaining consistent quality standards. These efficiencies often outweigh the upfront costs of purchasing and integrating automation systems.

Yes, the initial investment in hardware, software, and implementation can be steep. However, the long-term advantages - such as faster processing times, fewer mistakes, and the ability to adjust to new standards - make automation a smart move for companies aiming to scale while keeping quality high. Many businesses discover that these investments not only lower operational costs but also provide a competitive edge in their industry.