Real-time 3PL data monitoring is transforming how direct-to-consumer (DTC) brands handle logistics. By replacing slow, outdated systems with live tracking tools like GPS, IoT sensors, and RFID tags, brands can improve delivery accuracy, reduce errors, and respond instantly to supply chain challenges. This approach is no longer optional - customers expect precise delivery updates and fast problem resolution.

Here’s why it matters and how to do it effectively:

- Why It’s Important: Real-time data helps brands avoid delays, inventory mismatches, and dissatisfied customers. Without it, outdated systems cause inefficiencies and harm customer trust.

- Key Benefits: Faster order fulfillment (up to 25%), fewer inventory errors (20% reduction), and better customer satisfaction during peak times like Black Friday.

- Challenges to Address: Integration with legacy systems, ensuring data accuracy, and managing security risks.

- Best Practices:

- Use unified software systems (WMS + TMS) for synchronized data.

- Leverage IoT sensors and RFID tools for precise tracking.

- Train teams on data governance and invest in reliable hardware.

Pro Tip: Platforms like Forthmatch can help you find 3PL providers with the right technology to support real-time monitoring, saving time and improving logistics efficiency.

Real-time tracking isn’t just a tool - it’s a competitive edge in today’s fast-paced eCommerce world.

Using Power BI to track real-time deliveries of a 3rd-Party logistics business

Common Problems in Real-Time 3PL Data Monitoring

Real-time monitoring offers clear benefits, but it’s not without its challenges. For DTC brands, understanding these obstacles is crucial to navigating potential pitfalls and developing effective solutions. Below, we explore some of the most common issues and practical ways to address them.

Integration Problems with Legacy Systems

Outdated software is a major stumbling block for DTC brands aiming to implement real-time monitoring. Many 3PL providers still depend on legacy warehouse management systems (WMS) that lack support for modern APIs, making seamless data connections a challenge. These older systems often use proprietary formats, forcing brands to rely on manual data integration or invest in costly middleware solutions. The result? Data silos, slower decision-making, and operational inefficiencies.

Consider this example: A DTC brand using a legacy WMS without real-time API capabilities faced frequent inventory mismatches. This led to overselling and delayed shipments - issues that directly impacted customer satisfaction. However, after upgrading to a modern WMS with real-time data capture and automated alerts, the brand reduced order errors by 30% and significantly improved delivery times. This case highlights how addressing integration challenges can yield measurable improvements.

Beyond operational headaches, these integration issues often come with financial consequences. Brands may need to allocate resources for middleware, IT staff, or system upgrades to achieve the necessary level of integration for effective monitoring.

Data Accuracy and Information Overload

Manual data entry and inconsistent capture methods are frequent culprits behind accuracy problems in real-time monitoring systems. When warehouse workers rely on outdated barcode scanners or manually input data, errors can ripple through the supply chain. These inaccuracies lead to inventory discrepancies, delayed shipments, and dissatisfied customers - ultimately harming a brand’s reputation and revenue.

Another challenge is the sheer volume of data these systems generate. Without clear governance practices or specific KPIs, teams can become overwhelmed by irrelevant information, leading to "analysis paralysis." This can delay critical decisions and obscure actionable insights.

To ensure data accuracy, reliable hardware is essential. Modern WMS solutions depend on consistent input from tools like barcode scanners, RFID tags, and IoT sensors. Faulty or outdated equipment disrupts data flows, undermining the system’s reliability. Regular maintenance and timely upgrades are non-negotiable.

Security and Privacy Risks

Real-time monitoring introduces continuous data streams, which can expand security vulnerabilities. For DTC brands managing sensitive customer information, a single breach can result in fines, reputational damage, and a loss of trust.

Interconnected systems are particularly vulnerable. A breach in one area can compromise the entire network, and internal risks - such as improper access controls - can also expose sensitive data. Compliance with regulations like CCPA and GDPR adds another layer of complexity to securing real-time data flows.

Experts recommend a layered security approach to mitigate these risks. Strategies include end-to-end encryption, regular vulnerability assessments, and comprehensive employee training on data privacy. Partnering with technology providers who specialize in logistics security and staying current with regulatory changes are also key steps to protecting data integrity and ensuring compliance.

Best Practices for Real-Time Data Monitoring

These strategies tackle integration, accuracy, and security challenges while laying the groundwork for sustained growth.

Use Unified Software Systems

Centralizing data is critical for overcoming integration hurdles. Unified data tracking forms the core of effective real-time monitoring. By connecting Warehouse Management Systems (WMS) and Transportation Management Systems (TMS), DTC brands can eliminate data silos. This creates a single, reliable view of logistics activities, from inventory levels to delivery updates.

With unified systems, data flows are automated, cutting down on manual errors and simplifying inventory management. For example, a WMS can automatically reorder stock when inventory hits a pre-set threshold, avoiding stockouts without requiring human input. Similarly, an integrated TMS can streamline freight operations and provide customers with precise delivery timelines.

To minimize risks, consider piloting the system in one warehouse first. This approach helps identify and resolve technical issues while building staff confidence without disrupting overall operations.

The success of these systems hinges on seamless communication. Choose platforms with strong API capabilities and compatibility with modern data formats. This ensures smooth data exchange with suppliers, carriers, and other logistics partners.

Implement IoT and Sensor Technology

Building on unified systems, IoT sensors, GPS tracking, and RFID scanners take real-time monitoring to the next level. These tools offer minute-by-minute updates on vehicle locations, enabling route optimization and faster deliveries. RFID scanners automate inventory tracking, significantly reducing errors compared to traditional barcode systems.

IoT sensors add another layer of visibility by monitoring environmental conditions. This is especially critical for brands shipping temperature-sensitive items, cosmetics, or electronics. For instance, if a sensor detects a temperature spike, it can send an alert immediately, helping prevent product damage.

Automated RFID systems boast accuracy rates of 99.5% to 99.9%, far outpacing manual counts, which typically range from 95% to 98%. This improvement can directly reduce write-offs and enhance customer satisfaction by minimizing errors.

Many IoT solutions offer flexible pricing, allowing businesses to start small - perhaps focusing on high-value or sensitive products - and expand coverage as they see results.

Establish Data Governance and Employee Training

Even the most advanced tools need robust governance to ensure data accuracy and security. Clear standard operating procedures (SOPs) are essential for maintaining reliable data quality. Without consistent processes, even the best systems can produce flawed results. Invest in dependable hardware and detailed protocols to minimize human error during data capture.

Hands-on training and thorough documentation are vital for helping staff adopt new tools effectively. Your team should not only know how to use the tools but also understand how to interpret and act on real-time data to maximize its value.

Routine audits and automated validation checks are key to maintaining data integrity. These processes can flag issues early, preventing them from affecting customer orders or inventory decisions. Regular audits also highlight areas where additional training may be needed.

Involving stakeholders early in the process can smooth the adoption of new systems. When warehouse staff, customer service teams, and management understand the benefits of real-time monitoring, they’re more likely to embrace the changes.

Keep in mind that data governance isn’t a one-and-done task. As your business grows and technologies evolve, your procedures and training programs will need to adapt. Regular reviews ensure your systems continue delivering accurate, actionable insights that support smarter decision-making across your logistics operations.

sbb-itb-eb0f906

Technology Tools and Platforms for Real-Time Monitoring

Tackling earlier hurdles like integration issues and data inaccuracies, certain technologies now form the backbone of real-time monitoring. For effective 3PL data tracking, direct-to-consumer (DTC) logistics operations rely on a mix of software and hardware that provides immediate visibility and control.

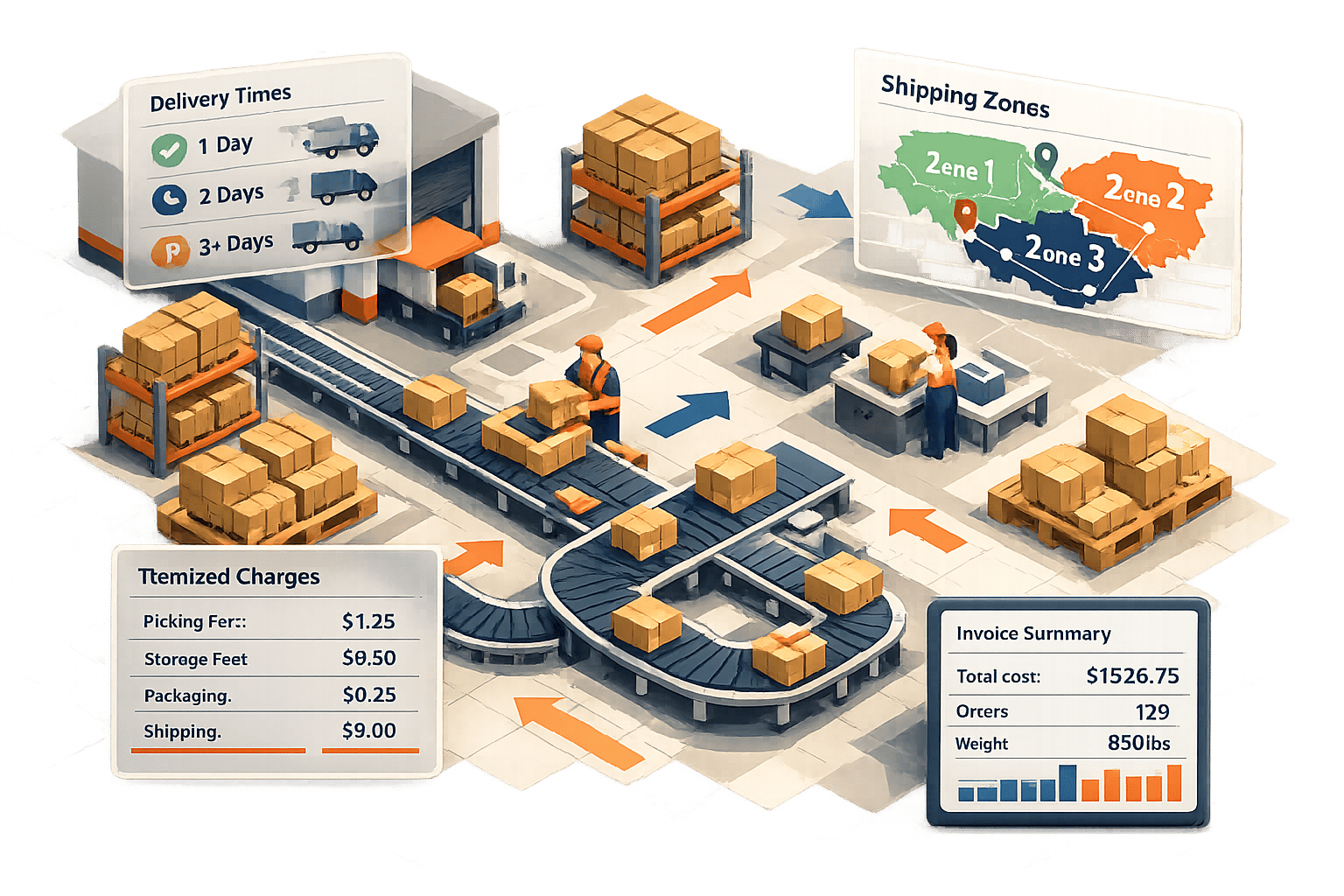

Core Software and Hardware Solutions

Warehouse Management Systems (WMS) are essential for tracking inventory down to the SKU level. They automatically update stock counts and seamlessly connect with eCommerce platforms via APIs or EDI connections, ensuring inventory accuracy and synchronization.

Transportation Management Systems (TMS) handle freight movement and optimize deliveries. These systems offer real-time shipment visibility, enable route planning, and allow dispatchers to make instant adjustments based on traffic or last-minute delivery changes. Together, WMS and TMS create a comprehensive view of products, from warehouse shelves to the customer’s doorstep.

Analytics dashboards bring data from various sources into one place, providing actionable insights. These dashboards help managers identify trends, pinpoint bottlenecks, and make informed decisions. By using real-time dashboards, companies can cut order errors and reduce delivery delays by up to 30%.

On the hardware side, RFID scanners streamline inventory tracking with precision, while IoT sensors monitor conditions like temperature and humidity - critical for goods that are sensitive to environmental changes. These sensors have been shown to lower spoilage rates for perishable items by 15–20%.

GPS devices and telematics supply real-time updates on vehicle and shipment locations, enabling last-mile delivery optimization. Dispatchers can reroute drivers instantly to avoid traffic or accommodate order changes.

Cloud-based platforms further enhance scalability and remote access. Many DTC brands are also incorporating AI and machine learning for predictive analytics and demand forecasting, particularly during high-demand periods like Black Friday.

These tools establish a strong foundation for selecting a 3PL partner that meets advanced technological standards.

How Forthmatch Supports Better 3PL Decisions

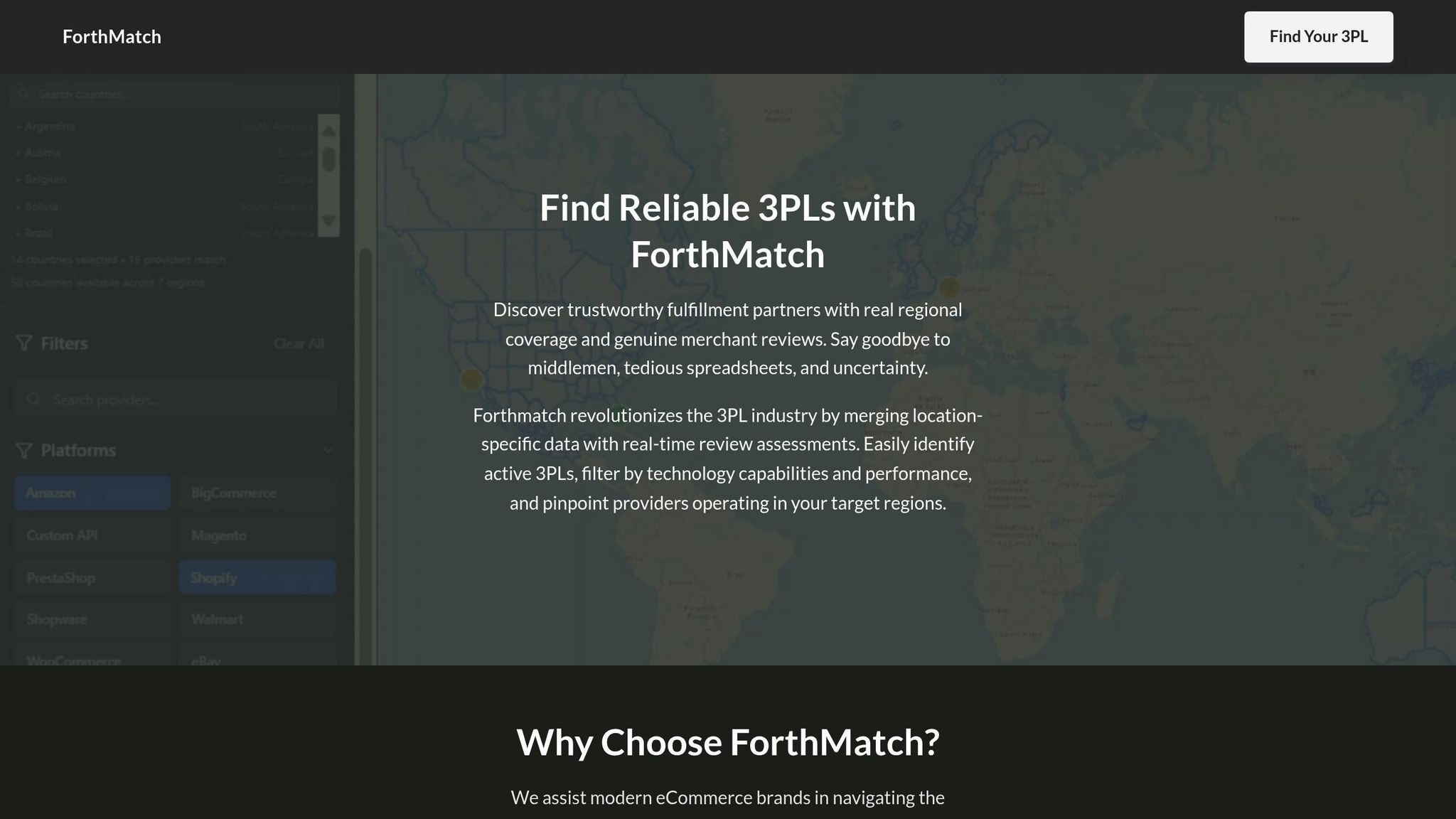

Selecting the right 3PL partner is critical for real-time monitoring success. That’s where Forthmatch steps in - a free, global directory designed specifically for DTC brands to find vetted 3PL providers.

The platform simplifies the comparison of fulfillment partners by delivery reach, compatibility, pricing, and firsthand feedback. This makes it especially useful for assessing a 3PL's technology and integration capabilities.

Forthmatch offers features like real-time service area maps and filters tailored to your eCommerce needs.

One standout feature is its Market Based Matching tool. By syncing with your eCommerce platform, it identifies your primary sales markets and highlights 3PLs that operate in those regions. This removes the guesswork when evaluating a partner’s ability to serve your customer base.

The platform also includes reviews and reputation data from sources like Google and Trustpilot, giving you insights into each provider's reliability and responsiveness - key factors in real-time monitoring partnerships.

"Our experience with Forthmatch was a game-changer. Thanks to their platform, we found a 3PL that perfectly fits our needs and saved $600 per month while gaining valuable visibility into our operations." - CLAIRE RASMUSSEN, CEO OF SOME COMPANY

Unlike traditional brokers, Forthmatch doesn’t rely on lead generation commissions or referral fees. This ensures unbiased access to fulfillment data, empowering DTC brands to make decisions based on actual capabilities, not sales pitches.

Additionally, the platform simplifies the process of evaluating potential 3PL partners. Instead of juggling multiple demo calls and filling out endless quote forms, brands can instantly compare capabilities, integrations, and service areas in one place. This streamlined approach is invaluable for quickly identifying 3PLs equipped with the technology needed for real-time monitoring.

Best Practices for Continuous Improvement in Real-Time Monitoring

Real-time monitoring thrives on constant updates, adapting to evolving technology to boost efficiency, accuracy, and customer satisfaction. Once integration and accuracy hurdles are addressed, continuous improvement ensures these systems stay relevant in a fast-changing market. By leveraging integrated systems and unified data flows, businesses can keep their tools aligned with shifting demands.

Monitor Key Performance Indicators (KPIs)

Keeping an eye on the right metrics is the cornerstone of any improvement strategy. Key performance indicators like fulfillment accuracy, inventory levels, order cycle time, transit times, and on-time delivery rates provide a clear snapshot of how well the system is performing.

Take fulfillment accuracy, for instance - it has a direct impact on customer satisfaction and return rates. A decline in this metric might signal issues with inventory tracking or warehouse processes. Similarly, transit times can highlight bottlenecks in shipping, while on-time delivery rates reflect the overall efficiency of the logistics chain under real-world conditions.

A great example comes from Black Friday 2023, when an e-commerce 3PL used AI-driven demand forecasting and real-time tracking to cut stockouts by 18% and improve fulfillment speed by 22%.

Real-time data also enables dynamic inventory management at the SKU level. Instead of relying on periodic updates, systems can automatically adjust stock levels and trigger reorder points based on actual demand patterns. This minimizes manual errors and helps avoid both stockouts and excess inventory situations.

To stay focused, set specific goals for each KPI. During normal operations, weekly reviews are sufficient, but during high-demand periods like the holidays, daily reviews ensure teams can quickly adapt to changes.

Keep Up with New Technology Trends

The logistics technology landscape is evolving rapidly, and staying updated on emerging trends is essential for maintaining strong performance. Current advancements include AI-powered analytics, blockchain for secure data sharing, and advanced IoT sensors.

AI and machine learning now go beyond basic forecasting, offering predictive insights that help brands fine-tune demand forecasts, optimize inventory, and streamline warehouse operations. Blockchain technology adds an extra layer of trust and transparency by enabling secure data sharing across the supply chain, reducing disputes and improving collaboration.

Meanwhile, modern IoT sensors have advanced beyond simple tracking to monitor critical environmental factors for sensitive products. For example, in November 2022, a leading US-based 3PL used real-time analytics and IoT sensors to manage perishable goods during the holiday season, cutting spoilage by 20% and improving on-time deliveries by 12%.

To stay ahead, attend industry conferences, subscribe to logistics tech publications, and run pilot programs for promising innovations. Testing new solutions at a single warehouse or with specific product lines minimizes risk while providing valuable performance insights.

Integrated platforms also play a key role by consolidating data from warehouse management, transportation, and analytics systems into a single source of truth.

Work with Technology Partners

Beyond upgrading technology, strong partnerships with tech providers are crucial for long-term success. These partnerships ensure access to ongoing support, regular updates, and new features. They’re especially helpful when integrating complex systems or resolving technical challenges.

Technology partners bring expertise that many DTC brands may lack, such as knowledge of API integrations, data security, and compliance requirements. Their input can speed up issue resolution and improve system performance.

Regular communication is key. Participating in beta testing programs or scheduling quarterly review meetings allows businesses to address performance issues, discuss upcoming features, and align technology goals with operational needs.

Continuous improvement is an ongoing journey. Markets shift, customer expectations evolve, and new technologies emerge all the time. Brands that embrace this mindset and make improvement a core part of their operations consistently outperform those that treat monitoring systems as a one-time setup.

Conclusion: Next Steps in Real-Time 3PL Data Monitoring

Real-time 3PL data monitoring has become a cornerstone for DTC brands aiming to maintain an efficient and reliable supply chain. By leveraging integrated systems, businesses can gain instant, actionable insights that drive better decision-making across their logistics operations. Here’s how to approach building and refining your monitoring system.

Steps for Improving Real-Time Monitoring

Start with a thorough audit of your logistics technology stack to pinpoint gaps in real-time visibility. Integrate systems like WMS (Warehouse Management System) and TMS (Transportation Management System) to ensure seamless data synchronization across your supply chain. This integration is the foundation for achieving the consistent data flow necessary for accurate, real-time insights.

Next, implement IoT sensors and RFID technologies to automate inventory tracking and monitor conditions like temperature and humidity. These tools help reduce errors and waste while improving fulfillment accuracy - often reaching rates between 99.5% and 99.9% - which is critical for maintaining customer trust and minimizing costly returns.

Establish clear data governance policies and train your team to interpret and act on real-time data effectively. This includes setting protocols for data sharing between internal teams and 3PL partners. Regular training ensures employees can leverage insights for operational improvements, turning raw data into actionable strategies.

Before a full-scale rollout, pilot your new system in a single warehouse. Use key performance indicators (KPIs) like order accuracy, on-time delivery rates, inventory precision, and transit times to measure the system’s success and make adjustments as needed.

Finally, prioritize security by requiring encryption, frequent firewall updates, and regular security audits for all 3PL partners. Clear agreements on data sharing and compliance with privacy regulations like GDPR or CCPA add another layer of protection.

How Forthmatch Simplifies 3PL Selection

As you enhance your monitoring capabilities, choosing the right 3PL partner becomes critical. This is where Forthmatch can help. Forthmatch offers a free, global directory of vetted 3PL providers, empowering you to compare options based on delivery reach, platform compatibility, pricing, and real merchant feedback. These factors directly impact your ability to build an effective monitoring system.

With Forthmatch's real-time service area maps and feature-based filters, you can quickly identify providers that align with your technological needs. Whether you require specific integrations or advanced reporting capabilities, the platform ensures you find partners equipped to meet your requirements. Plus, its direct contact feature eliminates brokers, allowing you to negotiate directly with providers, avoiding hidden fees and markups.

Forthmatch also integrates seamlessly with your e-commerce platform. By analyzing your primary markets, it identifies relevant 3PLs, simplifying the process of finding partners who can deliver real-time visibility where you need it most. With no referral fees or commissions, the platform provides unbiased access to data, enabling you to make decisions based purely on operational fit.

FAQs

What can DTC brands do to address integration challenges with legacy systems for real-time 3PL data monitoring?

Direct-to-consumer (DTC) brands often face hurdles when trying to integrate with older systems. A practical solution? Partnering with third-party logistics (3PL) providers that work seamlessly with their existing platforms. Tools like Forthmatch make this process much easier by helping brands pinpoint fulfillment partners that align with their operational and technological needs.

With Forthmatch, businesses can filter providers based on integration compatibility, delivery coverage, and other critical factors. This approach ensures that brands can connect with partners who not only match their tech stack but also enable efficient real-time data tracking. Selecting the right 3PL partner can help DTC brands simplify their operations and improve logistics performance significantly.

What are the best security practices for safeguarding real-time data in 3PL operations?

To safeguard real-time data in 3PL operations, it's crucial to adopt strong security measures that address both digital and operational threats. Start with end-to-end encryption to secure data during transmission, ensuring it remains protected from unauthorized access. Pair this with multi-factor authentication (MFA) to strengthen user access controls and add an extra layer of protection.

Keep your systems secure by regularly updating software to fix vulnerabilities and performing routine security audits to spot and resolve potential issues. Implementing strict access controls - allowing only authorized personnel to handle sensitive data - can further reduce the risk of breaches. Together, these strategies form a solid approach to protecting logistics data in dynamic, real-time settings.

How can real-time data monitoring improve customer satisfaction during busy shopping events like Black Friday?

Real-time data monitoring is a game-changer for DTC brands, especially during high-demand events like Black Friday. It empowers businesses to make quicker, smarter decisions by providing live insights into inventory levels, shipping progress, and fulfillment performance. This ensures orders are processed and delivered smoothly, even when the pressure is on.

With access to precise, up-to-the-minute data, brands can tackle potential delays head-on, fine-tune their supply chain processes, and keep customers informed every step of the way. The result? A smoother shopping experience that not only satisfies customers but also strengthens trust and loyalty during these crucial sales events.