When working with a 3PL (third-party logistics) provider, safety compliance isn't just about avoiding fines - it's about protecting workers, inventory, and your brand's reputation. Warehouses are prone to accidents, and poor safety practices can lead to injuries, shipment delays, and even customer trust issues. Here's what you need to know:

- Training Matters: Workers need ongoing training on hazard recognition, equipment handling, and emergency procedures. OSHA certification for equipment like forklifts and proper PPE usage is critical.

- Emergency Preparedness: Clear evacuation plans, fire safety protocols, and regular emergency drills ensure quick and effective responses during crises.

- Regulatory Compliance: OSHA standards cover PPE, lockout/tag-out procedures, hazard communication, and more. Regular audits and updated protocols are non-negotiable.

- Warehouse Design: Organized layouts with clear pathways, proper signage, and ergonomic workstations reduce risks.

- Equipment Maintenance: Routine checks for forklifts, racking systems, and conveyor belts prevent mechanical failures and accidents.

- Technology: Automation, sensors, and safety management software can monitor risks in real-time and improve overall safety.

For DTC brands, choosing a 3PL with strong safety practices ensures smooth operations and protects your reputation. Always ask for safety records, compliance details, and emergency plans when evaluating providers.

Top Warehouse Policies & Procedures: Safety, Efficiency, & Compliance

Workforce Safety Training and Education

Training is the backbone of a safe warehouse environment. It equips employees with the skills to recognize hazards, handle equipment responsibly, and respond effectively in emergencies. The supply chain industry has one of the highest rates of workplace injuries, making ongoing safety training and inspections a must for reducing risks. When a 3PL commits to thorough training, they’re safeguarding not only their workers but also your brand’s reputation.

Safety Training Programs

An effective safety training program focuses on three key areas: hazard recognition, equipment handling, and emergency procedures. Employees must learn to identify risks like blocked pathways, improper storage, or faulty equipment before they lead to accidents. This requires a mix of classroom instruction, hands-on demonstrations, and digital resources that employees can revisit anytime.

For example, OSHA mandates certification for forklift operators, but it’s wise to expand this certification to cover all essential warehouse equipment. Regular hands-on training and periodic refreshers ensure employees stay sharp. Supervisors should also perform spot checks to confirm that safety protocols are being followed correctly.

Providing personal protective equipment (PPE) is another OSHA requirement, along with training workers on its proper use. It’s not enough to tell employees what to wear - they need to know when and how to use PPE effectively. Make sure PPE is stored in easily accessible areas, and supervisors should ensure it’s being used, not left unused in lockers.

Emergency drills for scenarios like fires, chemical spills, or evacuations are equally important. These exercises build muscle memory, helping workers react quickly and appropriately during crises. Drills also expose weaknesses in your emergency plans, giving you a chance to fix them before a real incident occurs.

Consider this: In 2023, a leading 3PL provider ran monthly safety drills and quarterly quizzes, cutting workplace accidents by 25% over the year. Their program emphasized hazard recognition, equipment handling, and emergency response, proving that consistent practice leads to better safety outcomes.

Visual aids like floor markings, safety signs, and incident reviews can reinforce training. For instance, when workers see how past accidents happened and what could have prevented them, safety becomes more tangible and less abstract.

A well-structured training program doesn’t just teach - it fosters a culture where safety is everyone’s responsibility.

Building a Safety-Focused Culture

Training lays the groundwork, but creating a culture of safety ensures these practices become second nature. Leadership plays a critical role here. When managers prioritize safety - through daily briefings, open discussions about hazards, and a no-blame approach to reporting near-misses - it sets the tone for the entire team.

Incentive programs can also transform safety from a requirement into a shared value. Take the example of a 3PL warehouse in California that introduced a safety rewards program in 2022. Employees were encouraged to report hazards and participate in drills, with rewards like public recognition, small bonuses, or extra break time. The result? A 30% increase in hazard reporting and a 15% drop in accidents. These small acknowledgments can go a long way in keeping employees engaged and vigilant.

Team accountability amplifies this effect. When safety metrics are a shared responsibility, workers naturally look out for each other, reminding their peers to follow protocols and taking pride in their collective safety record.

To keep safety top of mind, integrate it into daily routines. Start shifts with a quick safety briefing about specific risks for the day. Empower employees to pause work if they notice a hazard, and make reporting easy and immediate. When safety becomes as automatic as clocking in, it’s no longer seen as extra effort.

Tracking progress is essential to maintaining a strong safety culture. Monitor incident rates, near-miss reports, training completion, and audit results. Use employee surveys to gauge whether workers feel safe, not just whether they say they do. Third-party audits can offer an unbiased assessment of your 3PL’s safety practices.

For DTC brands evaluating 3PL partners, these cultural aspects are just as important as training programs. Look for providers who adhere to OSHA standards, maintain current training records, and conduct regular safety audits. A 3PL that prioritizes open communication, continuous training, and technology-driven safety monitoring will protect not just your inventory but also your brand’s reputation far better than one that treats safety as an afterthought.

Regulatory Compliance and Standards Management

Sticking to federal safety regulations is the backbone of a safe warehouse operation. For 3PL warehouses in the U.S., OSHA (Occupational Safety and Health Administration) standards provide the essential framework to protect workers from injuries and illnesses. Following these rules isn’t just about avoiding penalties - it’s about safeguarding your inventory, your brand’s reputation, and the well-being of the people handling your products.

The warehousing and storage industry faces an injury rate of 5.1 per 100 full-time workers, which is higher than the national average across all industries. This statistic underscores why compliance is critical. Non-compliance can lead to accidents, legal troubles, operational shutdowns, and damage to your brand. For DTC brands, selecting a 3PL partner with a strong safety record is as crucial as assessing their shipping speed or tech capabilities. Let's take a closer look at the key OSHA regulations that set the standard for safety.

Key OSHA Regulations

OSHA regulations cover a wide range of warehouse safety aspects, from equipment usage to chemical storage. Familiarity with these rules can help you determine if a 3PL partner prioritizes safety or merely treats it as an afterthought.

- Personal Protective Equipment (PPE): OSHA mandates that employers provide PPE at no cost to workers and train them on proper usage. This includes items like hard hats, safety glasses, steel-toed boots, gloves, and high-visibility vests. Workers must understand when and how to use this equipment. If a 3PL skimps on PPE or training, it puts both its workers and your products at risk.

- Lockout/Tag-Out Procedures: These protocols ensure machinery doesn’t accidentally start during maintenance or repairs. Equipment like forklifts, conveyor belts, and automated systems must comply with these safety measures.

- Hazard Communication Standard (29 CFR 1910.1200): This regulation governs the handling of chemicals and hazardous materials. Containers must have proper labels with signal words, pictograms, and hazard statements. Additionally, Safety Data Sheets (SDS) must be accessible to employees who may come into contact with these substances. If your products involve items like cleaning supplies or batteries, this regulation directly impacts your 3PL’s storage and handling practices.

- Fire Safety Protocols: Warehouses must have fire extinguishers, sprinkler systems, and emergency lighting in place. Emergency exits must always remain clear and visibly marked. These measures can prevent small incidents from turning into major disasters.

- Signage and Clear Aisles: OSHA requires proper signage for danger zones, clearly marked equipment paths, and unobstructed emergency exits. Floor markings should indicate pedestrian walkways, forklift lanes, and hazardous areas.

- Forklift Safety: OSHA mandates that only certified operators handle forklifts. Pre-shift inspections and up-to-date maintenance records are also required. Since forklift-related incidents are a leading cause of warehouse injuries, adherence to this regulation protects both workers and inventory.

Common OSHA violations include issues with hazard communication, forklift safety, and lockout/tag-out procedures. When assessing a 3PL partner, ask about their compliance history in these areas. A poor track record in these categories is a clear warning sign.

Compliance Monitoring Process

Having safety regulations in place is one thing, but enforcing them is what truly matters. The top 3PL providers establish a dedicated compliance team to regularly monitor safety standards, conduct inspections, and update protocols as regulations evolve.

Monthly safety audits aligned with OSHA guidelines are a must. These audits should cover PPE availability, equipment maintenance, signage, and hazard communication. Findings must be documented, and corrective actions tracked until resolved. For example, a leading 3PL implemented a system of monthly digital audits conducted by a cross-functional compliance team, resulting in a 30% drop in safety incidents and flawless OSHA inspections.

Detailed record-keeping is another essential part of compliance. Warehouses should maintain logs of safety inspections, incident reports, training sessions, equipment maintenance, and corrective actions. These records show that safety isn’t just lip service - it’s an ongoing commitment.

Staying current with OSHA updates is equally important. Regulations change, and compliance teams must adapt by revising internal protocols and providing continuous training for employees. Subscribing to OSHA updates and participating in industry associations can help keep teams informed.

Technology can simplify compliance monitoring by automating inspections, incident tracking, and compliance metrics across facilities. Safety management software can send reminders for inspections or flag overdue maintenance tasks. Real-time monitoring systems and wearable devices can even alert workers and managers to hazards before accidents occur.

For DTC brands vetting 3PL providers, ask about their compliance processes. Do they have a dedicated safety team? How often do they conduct audits? Are they willing to share recent inspection results? Transparency in these areas signals accountability.

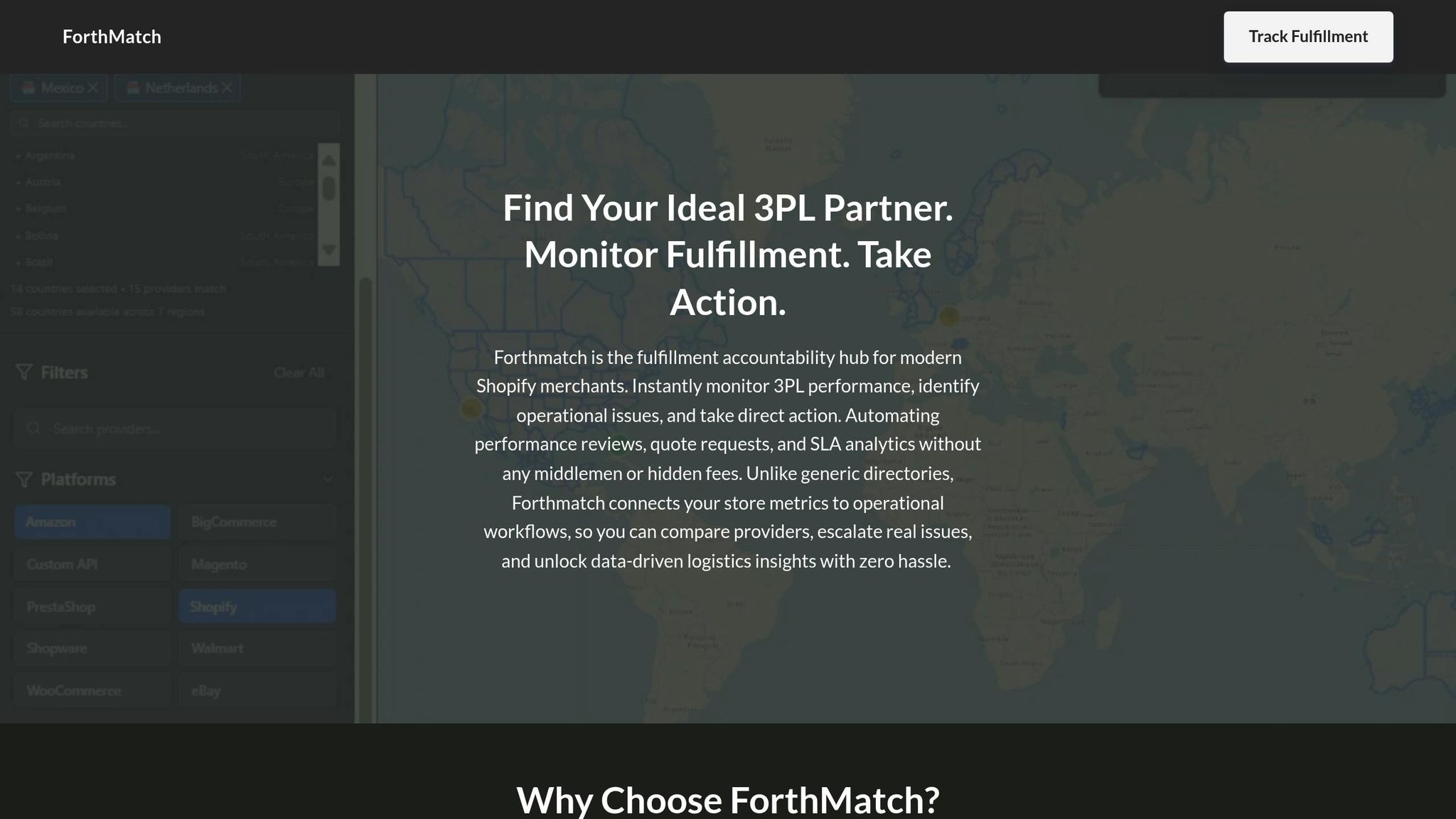

Platforms like Forthmatch can assist DTC brands in finding 3PL providers with strong safety and compliance records. By offering verified safety data, compliance certifications, and merchant feedback, Forthmatch helps brands choose partners that align with their regulatory expectations, reducing risks and ensuring smooth operations.

Regulatory compliance isn’t just about avoiding fines - it’s about fostering a safe warehouse environment where accidents are rare, workers are protected, and your brand remains trustworthy. A 3PL that prioritizes compliance demonstrates that they value safety as much as operational efficiency.

Warehouse Design and Equipment Maintenance

The setup and upkeep of a warehouse are crucial for preventing accidents and ensuring smooth daily operations. A well-planned layout combined with properly maintained equipment creates a safer and more predictable environment for workers and machinery. For DTC brands, it’s essential to understand how your 3PL provider approaches these aspects to ensure safety compliance remains a top priority.

Warehouse Layout for Safety

How a warehouse is organized has a direct impact on safety. Managing traffic flow effectively is one of the most important factors. Clearly marked forklift paths and designated zones for pedestrians help reduce the risk of collisions by keeping heavy machinery and people apart.

Ergonomic workstations also play a big role in reducing the risk of injuries. Packing stations, shelving, and equipment should be set up in a way that allows workers to access items without excessive stretching, bending, or repetitive movements that can lead to strain injuries. Poorly designed workstations can leave employees fatigued, increasing the likelihood of accidents.

Clear signage and visibility throughout the warehouse are essential for safe navigation. Emergency exits, hazardous areas, and storage zones should all be clearly marked so workers can quickly identify safe routes and potential dangers. Adequate lighting and unobstructed sightlines are equally important, as they help workers and equipment operators see each other, avoiding accidents.

Organized storage is another key safety measure. Properly labeled and securely stored inventory prevents tipping hazards and makes items easily accessible. When goods are stacked too high or stored carelessly, the risk of falling objects increases significantly.

Keeping aisles and pathways clear is critical for preventing slips, trips, and falls, as well as ensuring safe evacuation routes during emergencies. Cluttered walkways force workers to navigate around obstacles, which can lead to accidents. Open, well-defined paths create predictable movement patterns that improve overall safety.

A simple yet effective safety practice is implementing eye contact protocols. In high-traffic areas, equipment operators and pedestrians should make eye contact to acknowledge each other before proceeding. This small step can significantly reduce accident risks. Adding safety tape or barriers to separate walking areas from machinery zones provides a clear visual reminder of where each group should operate.

When choosing a 3PL provider, ask for detailed facility diagrams that show traffic flow, emergency exits, and hazard zones. Inquire about their workstation setups and how they reduce physical strain on workers. A reliable 3PL should be able to explain how their layout decisions contribute to a safer working environment.

While a well-organized layout reduces hazards, keeping equipment in excellent condition is equally important.

Equipment Maintenance Plans

Routine equipment maintenance is essential for preventing mechanical failures that can lead to injuries or damage to products. Equipment breakdowns not only disrupt operations but can also create dangerous situations for workers.

Forklifts, for example, need regular inspections and maintenance according to manufacturer guidelines. Given that forklift accidents are a leading cause of warehouse injuries, ensuring these machines are in good working order is non-negotiable.

Pallet racking systems also require regular checks to avoid collapses. Inspections should look for bent frames, damaged beams, and improper load distribution. Any compromised sections should be removed immediately to prevent accidents that could harm workers and destroy inventory.

Similarly, conveyor systems need consistent monitoring of belts, rollers, motors, and safety guards. These checks help ensure smooth operation and prevent entanglement hazards. Workers should also avoid loose clothing around conveyors, as it can easily get caught in moving parts. Properly maintained safety guards and emergency stop mechanisms are critical for protecting workers.

Inspection logs are vital for tracking maintenance activities, repairs, and equipment conditions. These logs not only demonstrate compliance during audits but also help identify recurring issues and hold maintenance teams accountable. Each log should include details like inspection dates, findings, corrective actions, and the technician responsible.

Technology can further enhance equipment safety. Real-time monitoring systems use sensors to track equipment performance and alert teams to potential issues before they escalate, reducing the risk of breakdowns. Warehouse Management Systems (WMS) integrated with these sensors can automate maintenance tracking, record equipment usage, and ensure compliance with safety standards. Additionally, temperature and environmental sensors monitor conditions in storage areas, alerting staff to malfunctions in refrigeration or climate control systems that could jeopardize both workers and products.

DTC brands should require their 3PL partners to maintain detailed maintenance logs that are easy to review. Ask for documentation like equipment certifications, training records, incident reports, and compliance checklists. A transparent 3PL should also provide maintenance schedules outlining inspection intervals, procedures, and replacement timelines.

Reputable 3PL providers typically offer regular summaries - monthly or quarterly - detailing maintenance activities, any issues identified, and the corrective actions taken. These reports demonstrate their commitment to safety and reliability. If a 3PL is unwilling or unable to share such information, it’s a warning sign of potential safety risks.

To meet safety standards, warehouses need to maintain clear emergency exits, proper signage, and organized traffic patterns. Equipment maintenance is equally vital for complying with OSHA regulations, as regular inspections help prevent mechanical failures that could lead to safety violations. By integrating thoughtful warehouse design with rigorous maintenance schedules, 3PL providers create a safer and more efficient environment where safety is built into everyday operations.

sbb-itb-eb0f906

Technology for Safety Monitoring

In addition to solid warehouse design and regular equipment maintenance, modern technology now plays a vital role in improving safety. By incorporating real-time monitoring and automated systems, warehouses can identify potential risks before they lead to injuries. For DTC brands, understanding how your 3PL partner leverages these technologies is critical to ensuring your products are handled in a safe and secure environment.

Automation and Real-Time Monitoring

Automation has transformed warehouse safety by taking workers out of harm's way. Robotics and conveyor systems now handle heavy lifting and material movement, reducing physical strain and minimizing the risk of injuries. Automated guided vehicles and robotic forklifts navigate high-traffic areas with precision, avoiding the fatigue or distractions that can lead to accidents. These systems help maintain smoother traffic flow and reduce congestion - key factors in preventing warehouse mishaps.

Sensors and video analytics are another layer of protection. These tools continuously monitor for anomalies, such as unusual vibrations or unsafe behaviors, and trigger immediate interventions when necessary.

Wearable safety devices, like smart helmets or vests, provide real-time feedback to workers. These devices alert employees when they enter hazardous zones or take unsafe actions, helping to correct risky behaviors on the spot.

Safety management software acts as the command center for monitoring activities. It generates automated alerts for overdue inspections, flags areas requiring attention, and provides audit trails to document how quickly hazards are addressed.

Data analytics further enhance safety by identifying patterns in historical incident data, near-miss reports, and environmental conditions. This allows 3PL providers to implement proactive measures, such as scheduling additional training during high-risk periods, increasing maintenance for critical equipment, or redesigning workflows in areas prone to accidents.

When choosing a 3PL partner, ask targeted questions about their safety technologies: What systems are in place to reduce manual handling? How do they use sensors to detect equipment issues? What wearable technology is deployed, and how is that data utilized?

These automated tools are essential for creating a broader framework of accountability, which platforms like Forthmatch help to reinforce.

Using Forthmatch for Safety Accountability

Beyond in-warehouse technology, platforms like Forthmatch ensure safety accountability through transparent tracking of performance metrics. Forthmatch provides a structured way to monitor safety compliance across your fulfillment operations, complementing the safety measures and practices established with your 3PL partners.

With Forthmatch, brands can set specific safety compliance metrics - such as incident rates, training completion percentages, audit scores, near-miss reporting frequency, PPE compliance, and equipment maintenance schedules - as key performance indicators (KPIs) or service level agreements (SLAs). The SLA Analytics Hub ($9/month) continuously tracks these metrics against established benchmarks and compliance goals.

The platform's Automated Provider Accountability feature simplifies the process of scheduling and documenting regular review meetings with 3PL partners. These meetings focus on safety performance, helping to establish baseline metrics, track progress on improvement plans, and ensure non-compliance issues are addressed promptly. Forthmatch centralizes safety performance data across all 3PL relationships, enabling brands to compare partners, identify those with the highest safety standards, and address areas needing improvement quickly.

Continuous monitoring, transparent data sharing, and structured accountability are key to maintaining safety compliance. Forthmatch equips you with the tools to make safety performance measurable and visible, ensuring your 3PL partners consistently meet your brand’s safety expectations.

Emergency Preparedness and Response Protocols

Emergencies like fires, chemical spills, medical incidents, or severe weather can strike warehouses without warning. The ability to respond effectively often hinges on preparation. For DTC brands working with 3PL partners, it’s crucial to understand how your fulfillment provider handles emergencies. A solid emergency preparedness plan is a cornerstone of warehouse safety.

According to OSHA, employers must have an emergency action plan that includes procedures for reporting fires, evacuation routes, and accounting for all employees. Given the higher injury rates in warehouses, these protocols aren’t optional - they’re essential.

Emergency Plans

A thorough emergency action plan starts with fire safety protocols tailored specifically for warehouses. Unlike office spaces, warehouses often house flammable materials, tall storage racks, and heavy machinery, all of which complicate firefighting efforts. Fire safety plans should detail the locations and maintenance of fire suppression systems, such as sprinklers, ensure fire extinguishers are easily accessible, and keep exits and aisles clear at all times.

Evacuation procedures are another critical element. Warehouses need multiple clearly marked evacuation routes, complete with signage pointing to the nearest exits and assembly points. Plans should also account for scenarios where certain exits might be blocked, providing alternative routes. Designated evacuation leaders and clear signage help ensure that staff can exit quickly and safely.

First aid protocols address immediate medical needs arising from common warehouse incidents like cuts, falls, or chemical exposure. First aid kits should be strategically located, and specific employees should receive certified training in first aid and CPR. These protocols must also include steps for contacting emergency medical services and documenting incidents, with regular checks on supplies and training records to ensure readiness.

For warehouses handling hazardous materials, emergency plans must include procedures for containing spills, evacuating affected areas, and notifying authorities. These measures should be practiced regularly during drills and integrated into the broader emergency action plan.

Communication during emergencies is equally vital. Staff need real-time updates through alarms, public announcements, or mobile alerts. The plan should designate who is authorized to activate emergency protocols and specify how information will reach all employees, including those in remote or off-site areas.

Emergency plans must be reviewed and updated regularly to reflect changes in warehouse layout, new equipment, or lessons learned from drills and past incidents. An outdated plan can leave dangerous gaps in emergency response.

The effectiveness of any plan depends on consistent training and drills.

Employee Training and Regular Drills

A plan is only as good as its execution. All new hires should receive training on fire safety, evacuation routes, first aid basics, and hazard communication. OSHA recommends annual refresher courses and additional training whenever there are significant changes to procedures or layouts.

To ensure everyone understands emergency protocols, training should include multilingual materials, visual aids, and hands-on demonstrations.

Emergency drills are where theory turns into practice. These should be conducted at least twice a year, though quarterly drills can further improve preparedness. Drills should simulate a variety of scenarios, such as fires, chemical spills, or severe weather. Each drill provides valuable feedback, allowing teams to identify weaknesses and refine their procedures.

For instance, in 2022, a 3PL warehouse in Ohio conducted quarterly fire drills. By incorporating feedback from these drills, they reduced their average evacuation time from 7 minutes to 4 minutes and decreased minor injuries during drills by 30%.

After every drill, a structured debrief should evaluate what worked and what didn’t. Were evacuation routes clear? Did employees reach their assembly points? Did communication systems function as intended? Were emergency leaders effective in their roles? These insights guide updates to training and procedures.

Given the high turnover rate in warehouse staffing, ongoing onboarding and refresher training are essential. Safety management software can help track training completion and flag employees in need of updates.

Creating a safety-first culture is key to combating complacency. Emergencies may be rare, and drills can feel disruptive, but leadership must emphasize that preparedness saves lives. Recognizing employees who excel during drills or contribute suggestions for improvement reinforces this mindset. Consistent performance during drills and transparent training records build a culture of accountability.

When evaluating 3PL partners, ask detailed questions about their emergency preparedness: How often are drills conducted? What scenarios are practiced? How do they train employees who speak different languages? What results have their drills produced? Can they provide documentation of training and drill outcomes? These questions reveal whether a provider takes emergency preparedness seriously or merely meets minimum compliance.

Tracking key metrics helps measure the effectiveness of emergency plans. Metrics like the number and outcomes of drills, training completion rates, response times, safety audits, and near-miss reports provide valuable insights for continuous improvement and OSHA compliance.

Technology can play a supporting role in emergency preparedness. Automated systems can schedule drills, track training, and send reminders. Wearable devices can deliver real-time hazard alerts, while automated alarms and evacuation guidance systems enhance response efforts. Mobile apps and digital checklists ensure protocols are accessible and up-to-date for all employees.

Emergency preparedness isn’t a one-time task - it’s an ongoing commitment to protecting people and operations. For DTC brands, working with 3PL providers that prioritize detailed planning, regular training, and realistic drills ensures fulfillment operations can withstand any crisis. Integrating these measures with technology further strengthens warehouse safety.

Conclusion

To wrap up, let's highlight how 3PL safety compliance directly contributes to operational success. Safety in warehouses isn't just about avoiding penalties - it's about safeguarding people, protecting inventory, and enabling smooth, scalable operations. For DTC brands partnering with 3PL providers, prioritizing safety practices lays the groundwork for sustained success.

At the heart of a strong safety culture is a well-designed training program. When 3PL employees are well-versed in spotting hazards, handling equipment, and following emergency protocols, safety becomes a shared responsibility across the organization. This not only reduces accidents but also enhances overall efficiency.

Staying compliant with OSHA regulations is critical - not just for protecting workers, but also for safeguarding your brand's reputation. With injury rates in the warehouse and storage sector sitting at around 5.1 cases per 100 full-time workers - higher than the national average - consistent and thorough compliance monitoring is essential.

Thoughtful warehouse design and routine equipment maintenance also play a key role in preventing accidents. These practical measures reflect a 3PL partner's commitment to creating a safe working environment.

Integrating automation and real-time monitoring further elevates safety standards. Tools like Forthmatch can help DTC brands evaluate 3PL providers based on their safety technology and feedback from other merchants. This allows you to choose partners who prioritize safety alongside operational performance. Technology, when combined with other safety measures, creates a well-rounded ecosystem that supports both workers and inventory.

Emergency preparedness is another cornerstone of effective safety management. Comprehensive plans, regular drills, and easily accessible resources ensure that when crises arise, their impact is minimized.

When assessing current or potential logistics partners, make safety a top priority. Ask about their training schedules, compliance processes, technological capabilities, and emergency readiness. Request documentation like safety audit results, drill reports, and incident logs. The partners who provide clear, detailed responses are the ones who will protect your operations and support your growth.

Ultimately, safety is an investment in resilience, employee well-being, and brand reputation. By focusing on these interconnected elements, DTC brands can build logistics systems that not only overcome challenges but also deliver consistent, reliable performance for the long haul.

FAQs

What are the essential OSHA safety regulations for 3PL warehouses?

To maintain safety and meet regulatory requirements, 3PL warehouses in the United States must follow essential OSHA (Occupational Safety and Health Administration) guidelines. These rules focus on creating a safe workplace by identifying and addressing hazards, offering employees thorough training, and ensuring the proper use of personal protective equipment (PPE).

Additionally, warehouses are required to meet standards for material handling, keep equipment in good working condition, and be prepared for emergencies. Routine inspections and clear reporting procedures play a key role in ensuring compliance and safeguarding workers from potential dangers.

What should DTC brands look for when assessing the safety practices of a 3PL provider?

When assessing a 3PL provider's safety practices, DTC brands should take a close look at their adherence to industry standards, employee training initiatives, and any relevant safety certifications. Additionally, examining their history of workplace incidents and their approach to risk management provides valuable insight into their commitment to maintaining a safe environment.

Platforms like Forthmatch can be incredibly helpful here. They allow brands to compare 3PL providers using real-world merchant feedback. This not only ensures transparency but also helps pinpoint partners with solid safety protocols, making it simpler to choose a provider that aligns with your operational needs and safety expectations.

How does technology improve safety and compliance in 3PL warehouses?

Technology significantly improves safety and compliance in warehouses managed by third-party logistics (3PL) providers. Tools like automated inventory systems, real-time tracking, and AI-driven monitoring minimize human error and help ensure safety regulations are met. These systems can pinpoint risks, optimize workflows, and keep compliance records precise and up to date.

Take IoT devices, for instance - they can track environmental factors like temperature and humidity to safeguard sensitive products. Meanwhile, automated reporting tools make audits and inspections much simpler. By using these advancements, 3PL providers can offer safer and more efficient warehouse operations, especially for their direct-to-consumer (DTC) partners.