Did you know hidden fees in 3PL contracts can quietly drain your profits? If you're running an eCommerce business, understanding 3PL pricing is non-negotiable. Here's what you need to know:

- 3PL Basics: Third-party logistics (3PL) providers handle storage, packing, and shipping for businesses, helping streamline operations.

- Pricing Models: Common options include fixed-rate, activity-based, cost-plus, and hybrid pricing. Each has pros and cons depending on your order volume and business needs.

- Hidden Fees: These include charges for long-term storage, returns processing, account management, and more. They can significantly impact your budget if overlooked.

- Cost Reduction Tips: Negotiate transparent contracts, improve inventory turnover, optimize packaging, and consider distributed fulfillment.

Key takeaway: Understanding 3PL pricing models and spotting hidden fees upfront can save you thousands annually. Dive into the full guide to learn how to choose the right provider and keep your logistics costs in check.

3PL Pricing Models Explained

Common Pricing Structures

The pricing model you choose for your 3PL services can significantly influence your storage, pick-and-pack, and shipping costs - and ultimately, your bottom line.

Fixed (Flat-Rate) Pricing is the simplest to predict. With this structure, you pay a consistent monthly fee, no matter how much you use the service. While this makes invoicing straightforward, it can lead to overpaying during slower months or extra fees during busy times.

Activity-Based Pricing works differently, charging only for the services you use each month. This model adapts to seasonal fluctuations, making it appealing for businesses with variable demand. However, costs can skyrocket during peak periods, and tracking multiple service charges can become a hassle.

Cost-Plus Pricing provides transparency by breaking down costs and adding a small markup, typically around 15%. While this model offers clarity, it requires diligent oversight to manage expenses, and it can make budgeting less predictable.

Hybrid Pricing combines elements from several models to create a tailored solution. It allows for scalability and customization, which can be beneficial for businesses with unique needs. However, this flexibility often comes with complex contracts that need careful review to avoid hidden fees.

The financial differences between these models can be dramatic. For example, a business processing 500 orders per month might pay around $2,000 with fixed pricing, compared to $1,700 with activity-based pricing. But as order volume grows to 20,000 per month, fixed pricing rises to about $10,000, while activity-based pricing soars to $57,500.

"The only way you can really get to an apples-to-apples 3PL price comparison is to calculate the total cost of fulfillment." - Tony Runyan, Chief Client Officer, Red Stag Fulfillment

| 3PL Pricing Model | Best For | Monthly Cost (500 orders) | Monthly Cost (20,000 orders) |

|---|---|---|---|

| Fixed (Flat-Rate) | Businesses with steady, predictable volumes | ~$2,000 | ~$10,000 |

| Activity-Based | Companies with seasonal demand | ~$1,700 | ~$57,500 |

| Cost-Plus | Enterprises or those without historical data | ~$1,600 | ~$55,000 |

| Hybrid | Growing mid-to-large businesses | ~$2,500 | ~$50,000 |

Note: These figures exclude outbound shipping costs, which are typically billed separately.

Beyond these core models, there are other options like transactional pricing and subscription-based pricing. Transactional pricing charges per use, offering flexibility but often at higher per-unit costs. Subscription-based pricing provides a fixed monthly rate, which is predictable but can lead to overages or underutilization risks.

Choosing the right model requires understanding how these structures fit your specific business needs.

How to Choose the Right Pricing Model

Selecting the right pricing model starts with analyzing your business’s order volume, seasonality, and transparency needs. The financial stakes are high, and making the right choice can significantly impact your growth and profitability.

Analyze your order volume patterns. If your business has consistent monthly orders with minimal seasonal variation, fixed pricing allows for predictable budgeting. This model shifts the risk of volume fluctuations to the 3PL provider. On the other hand, if your business experiences seasonal spikes - like holiday sales or back-to-school surges - activity-based pricing may be more suitable, as it adjusts to your usage.

Factor in your growth stage. Startups and smaller businesses often benefit from transactional or activity-based models, which align costs with growth and avoid overpaying in the early stages. Established businesses with steady sales may find fixed or subscription-based pricing better for long-term budgeting and operational stability.

Consider your need for cost visibility. If you require detailed breakdowns of logistics expenses, cost-plus pricing provides the most clarity. It shows exactly what you're paying for, along with a small markup. However, this model demands more involvement in managing the relationship and keeping expenses in check.

Assess your operational complexity. Businesses with straightforward fulfillment needs - like standard products and simple packaging - can often thrive with fixed or subscription-based pricing. Those with specialized requirements, such as custom packaging or complex inventory management, may find hybrid models more accommodating.

"You need to understand the full pricing structure - storage, pick-and-pack fees, shipping rates, and any potential surcharges. A clear view of your total costs can help avoid surprises and make sure the 3PL aligns with your budget." - Joe Spisak, CEO and Founder, Fulfill.com

Think about budget predictability. If consistent monthly costs are essential for financial planning, fixed or subscription-based pricing is a safer bet. Businesses with more flexible budgets or those willing to trade predictability for potential savings might lean toward activity-based or transactional models.

Evaluate your risk tolerance. Fixed pricing transfers the risk of volume changes to the provider, while variable models keep the risk on your business. In times of economic uncertainty, some businesses prefer the stability of fixed costs, while others value the flexibility to scale expenses up or down.

Transparency about your projected order volumes during contract negotiations is crucial. Being upfront helps secure better terms and ensures the pricing model aligns with your actual needs. The right choice can save thousands annually, making this decision a cornerstone of your business's financial and operational success.

3PL Fees: The Hidden Costs of Outsourcing Your Fulfillment

Standard Costs vs Hidden Fees in 3PL Contracts

Building on the earlier discussion of pricing models, let’s dive into the difference between standard fees and hidden charges in 3PL contracts. Understanding this distinction is crucial for keeping your logistics budget under control. While standard fees are clearly outlined in contracts, hidden fees often catch businesses off guard. Below, we’ll break down common standard costs and offer tips for spotting those sneaky hidden charges.

Standard Fees You Should Expect

Most 3PL contracts include predictable, upfront costs that form the backbone of your logistics budget. These are typically transparent and agreed upon during the negotiation phase.

- Storage fees: This is often one of the largest recurring expenses. Storage rates vary depending on the location and type of facility. For example, pallet storage can range from $5 to $15 per pallet per month. Some providers charge by cubic foot instead, with rates between $0.50 and $2.00 per cubic foot monthly.

- Pick-and-pack charges: These fees cover the labor involved in selecting and packaging items for shipment. You can expect to pay around $0.20 to $0.50 per item picked.

- Shipping fees: These are calculated based on the weight and dimensions of your shipment, as determined by standard carrier pricing. Many 3PLs pass through actual carrier rates from companies like UPS, FedEx, or USPS, though some may offer discounted rates.

- Receiving fees: These charges cover the cost of processing your inventory when it arrives at the warehouse. Labor for receiving typically costs between $25 and $50 per hour, with potential additional fees for inspection or quality checks.

- Order processing fees: These are flat charges applied to each order, usually ranging from $0.25 to $1.00 per shipment. They cover tasks like generating shipping labels and updating tracking information.

These standard fees should be clearly itemized in your contract, with specific rates and calculation methods spelled out. But even with these transparent costs, hidden charges can still creep in and disrupt your budget.

Finding Hidden Fees

Hidden fees are charges that aren’t clearly disclosed in the initial contract - yet they can significantly impact your bottom line.

- Long-term storage fees: While your contract might outline a standard monthly storage rate, additional penalties often apply for inventory stored beyond a set timeframe (e.g., 30, 60, or 90 days). These penalties can tack on an extra $5 to $25 per pallet per month.

- Minimum volume commitments: If your business doesn’t meet the agreed-upon monthly order levels, you could face penalties or higher per-unit rates. Be sure to ask, “Is there a monthly minimum fee or order volume requirement?” and “What happens if I don’t meet it?”.

- Returns processing fees: Handling returns - whether it’s inspecting, restocking, or disposing of items - can cost anywhere from $2 to $10 per item, depending on the complexity of the process.

- Account management fees: Some 3PLs charge recurring fees for account support, even if the level of service provided should fall under standard operations.

To help you identify common hidden fees, here’s a quick breakdown:

| Fee Type | Extra Charges For… | Also Known As… |

|---|---|---|

| Long-term storage | Inventory held beyond a set timeframe | Aging inventory fee, Slow-mover fee |

| Oversized/heavy items | Exceeding size or weight limits | Oversize surcharge, Dimensional weight fee |

| Returns processing | Inspecting, restocking, or disposing of returns | RMA fee, Restocking fee |

| Pick/pack extras | Complex order picking | Multi-unit pick fee, Batch pick charge |

| Packaging materials | Supplies like boxes, mailers, or dunnage | Packing supply fee, Materials surcharge |

- Out-of-scope charges: These apply to activities outside the contract’s defined scope, such as special labeling, additional kitting services, or extra quality inspections. These are usually billed hourly, with rates varying by provider.

- Shipping markups: While some 3PLs pass through standard carrier rates, others add a markup as a hidden revenue stream. This can inflate your shipping costs unexpectedly.

- Technology and integration costs: These include upfront fees for system setup or ongoing charges for API access and data reporting. Implementation costs can range from $500 to $5,000, often without being disclosed during initial negotiations.

To avoid surprises, request a full breakdown of potential charges during contract discussions. Ask for a mock invoice based on a realistic scenario tailored to your business needs. Creating a checklist of required services can also help ensure all costs are accounted for without unexpected extras.

In 2023, DavidsTea ended its partnership with a fulfillment provider after discovering hidden fees were significantly cutting into profitability. The company briefly handled logistics in-house and, despite lower revenue, ultimately achieved higher gross profits. This serves as a cautionary tale: hidden 3PL fees can erode margins more than many businesses anticipate.

Carefully reviewing contract terms - especially sections on additional services, minimum commitments, and fee schedules - can help you negotiate better terms and avoid unwelcome surprises.

sbb-itb-eb0f906

How to Reduce 3PL Costs and Avoid Hidden Fees

Cutting logistics expenses requires a mix of clear contract negotiations, operational improvements, and smart use of comparison tools.

Negotiating Clear Contracts

Keeping costs under control starts with negotiating contracts that leave no room for confusion. Approach these discussions as a partner looking to build a strong, long-term relationship with your 3PL provider while protecting your business interests.

Start by outlining your logistics requirements, expected volumes, and service expectations. Prioritize your must-haves and secondary needs to stay focused during negotiations. Ask for itemized pricing that breaks down charges for receiving, storage, pick-and-pack, and shipping. This level of detail helps you spot potential markups and negotiate more effectively.

Be proactive about addressing minimums, surcharges, and other potential fees. Clarify which services are included and which come with extra charges. Discuss how seasonal volume changes might affect costs and define what triggers additional fees. Make sure to include provisions that allow for scaling up or down as your business evolves.

Set clear performance standards tied to your business goals and include steps for improvement if those standards aren’t met. Regular performance reviews - quarterly or annually - can help ensure the partnership remains beneficial. It’s also wise to consult a legal advisor familiar with 3PL contracts to ensure the terms protect your interests.

Watch out for vague service descriptions, undefined fees, and unclear performance metrics. Make sure all potential costs - such as storage fees, handling charges, special project rates, and peak season surcharges - are spelled out upfront to avoid disputes later.

Once your contract is in place, focus on streamlining operations to further reduce costs.

Improving Storage and Fulfillment Efficiency

Operational efficiency is another key to lowering logistics costs. Fulfillment alone can account for 12%–20% of a company’s revenue, so optimizing these processes can make a big difference.

Start by improving inventory turnover. Moving stock faster not only lowers storage fees but also reduces the risk of penalties for aging inventory.

Reevaluate your packaging to avoid paying for unnecessary dimensional weight. Many businesses cut shipping costs by 10%–20% by using custom-fit packaging that eliminates wasted space. Plus, better packaging enhances the customer experience and reduces damage during transit.

Think about adopting a distributed fulfillment model, where inventory is stored closer to your customers. This approach can reduce shipping distances, speed up delivery times, and lower shipping costs - all while boosting customer satisfaction.

Automation is another game-changer. Automating tasks like order entry, shipping label creation, and customer notifications can improve pick accuracy to as high as 99.9%. Fewer errors mean fewer returns, which saves money and improves customer trust.

Speaking of returns, having a clear return policy and strong quality control measures can significantly reduce the volume of returns. Managing returns effectively not only saves money but also keeps customers happy.

These operational improvements work hand-in-hand with clear contracts to help you avoid unnecessary fees and keep costs in check.

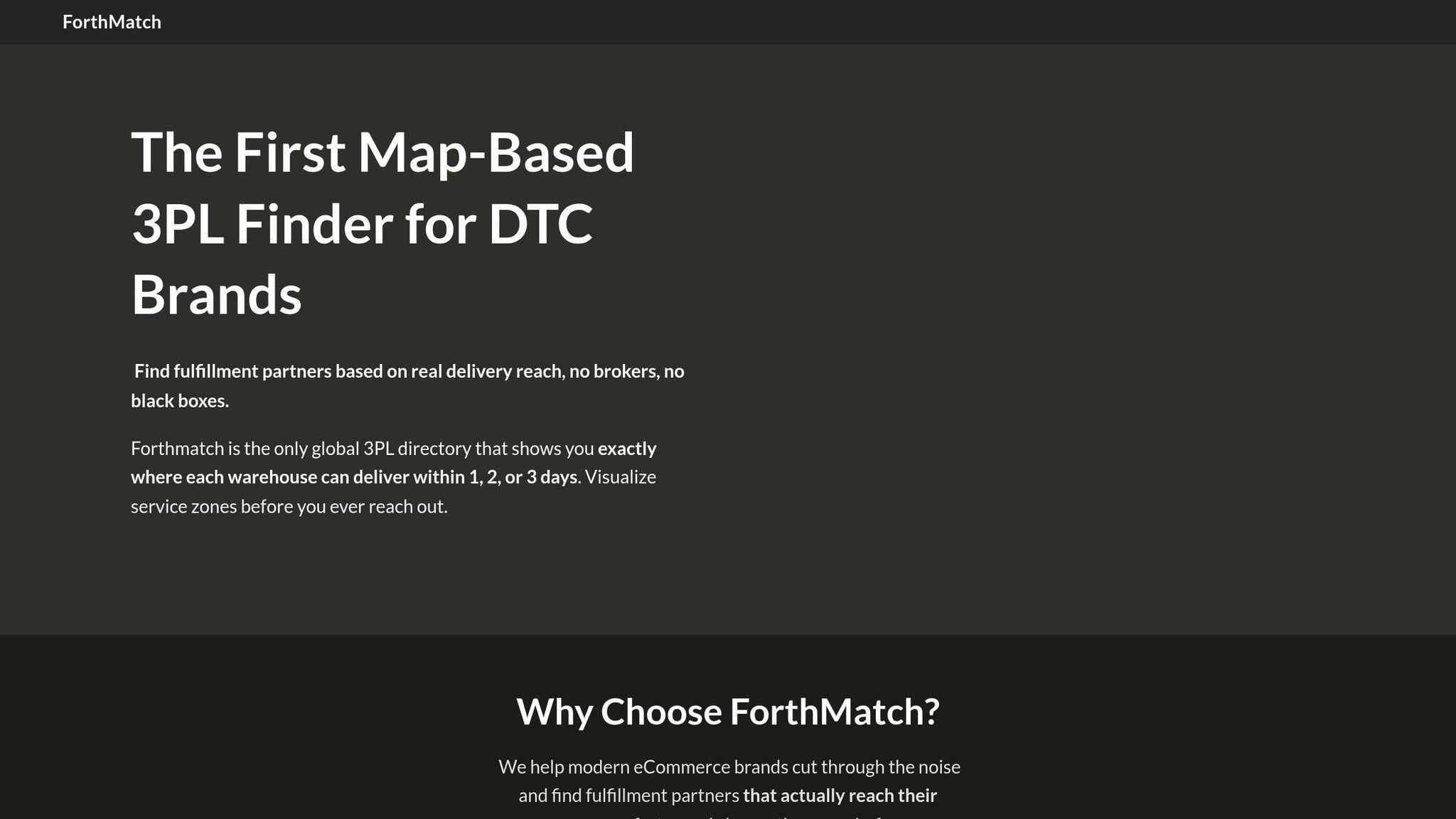

Using Forthmatch for Clear 3PL Comparison

To complement your internal strategies, consider using Forthmatch, a platform designed to simplify the 3PL selection process. Traditional methods often involve brokers, lengthy quote requests, and hidden fees that drive up costs. Forthmatch eliminates these inefficiencies by providing direct access to vetted 3PL providers.

The platform offers transparent pricing data, trust scores, and merchant reviews, helping you make informed decisions. Real-time service area maps use isochrones and isodistances to show each provider’s delivery reach, making it easier to implement distributed fulfillment strategies that save on shipping and speed up delivery.

Forthmatch also allows you to filter providers by region, specialty, platform compatibility, and other key features, ensuring you only consider options that meet your needs. You can negotiate directly with providers, bypassing middleman fees, and compare multiple options side by side.

Additionally, Forthmatch supports integration with major eCommerce platforms like Shopify, WooCommerce, and Amazon, reducing setup costs and technical headaches. Community reviews provide insights from other merchants, giving you a clearer picture of what to expect from each provider.

How to Evaluate and Compare 3PL Proposals

When evaluating 3PL proposals, it's crucial to dig into the details of both costs and services. A thorough review will help you find the right partner for your business while avoiding unexpected expenses later.

Step-by-Step Guide to Reviewing Proposals

Start by asking for itemized quotes that clearly outline every potential cost. As Karen Kroll points out:

"An inability to get clear pricing information is another red flag. A mature, sophisticated 3PL should be able to, when given a set of services and a forecasted volume of activity, calculate the expected cost."

Here are some key areas to focus on:

- Pricing transparency: Request a full rate sheet covering inbound receiving, storage fees, pick-and-pack charges, shipping costs, and any other handling fees. Be wary of vague proposals or unexplained charges.

- Service capabilities: Check whether the provider can handle your specific product types, such as fragile or perishable goods, and whether they can manage your expected order volumes. Also, review their reverse logistics processes for handling returns efficiently and in line with your procedures.

- Technology integration: Ensure their systems integrate smoothly with your platform. Look for features like real-time inventory tracking, automated order processing, and detailed reporting tools.

- Geographic coverage: Evaluate their warehouse locations in relation to your key markets. Proximity can significantly affect shipping costs and delivery times.

- Scalability and flexibility: Confirm that the provider can handle seasonal volume spikes, support new product launches, and adapt to changes in your business without excessive fees.

Be cautious of proposals with unclear terms or those that seem overly advantageous to the vendor. Shaun Neal, fulfillment lead at OpenStore, emphasizes:

"When choosing a 3PL offering, you'll want to consider factors that will impact the success of your business and the relationship you'll have with your customers."

Your final decision should be guided by the total cost of ownership, not just the base rates. Account for setup fees, minimum order requirements, and seasonal surcharges. In many cases, a provider with slightly higher base rates but fewer hidden costs may prove to be more economical over time.

To streamline your evaluation process, create a standardized framework with clear scoring criteria for pricing, service quality, technology, and geographic coverage. This structured approach can help you make more informed decisions.

Making Better Decisions with Forthmatch

Once you've completed a detailed review, platforms like Forthmatch can simplify the next steps by enabling direct comparisons of 3PL providers without additional intermediary fees.

Forthmatch offers tools like real-time service area maps, which use isochrones and isodistances to show each provider's delivery reach. This feature makes it easy to identify which providers can effectively cover your key markets, supporting strategies like distributed fulfillment to cut shipping costs and improve delivery speeds.

The platform also includes community-sourced reviews and trust scoring, which provide valuable insights from other merchants. These reviews can reveal hidden costs or service issues not immediately obvious in formal proposals.

By connecting you directly with 3PL providers, Forthmatch eliminates broker fees and referral markups. This direct access allows you to negotiate terms, compare options side-by-side, and make decisions based on unbiased, transparent information.

Forthmatch's data-driven approach incorporates trust scoring based on factors like public reputation, domain credibility, and performance metrics. This ensures you consider all aspects that contribute to building a successful long-term partnership.

Conclusion: Managing 3PL Pricing for eCommerce Success

Navigating 3PL pricing requires a thoughtful approach that accounts for both clear and hidden costs. As highlighted throughout this guide, understanding the full range of expenses is critical to creating a logistics strategy that supports the growth and profitability of your DTC brand.

With the global 3PL market surpassing $1 trillion in 2023 and expected to nearly double by 2030, the stakes are higher than ever for businesses to carefully evaluate their logistics expenses. This isn’t just about comparing price tags - it’s about understanding how pricing models influence daily operations, scalability, and long-term profitability.

Crafting an evaluation framework tailored to your business needs is essential. Whether you prefer a fixed-rate model for stability, an activity-based approach for flexibility, or a hybrid structure for customization, your choice should align with your goals and budget. That said, even the most well-thought-out framework must leave room for unexpected charges.

Hidden fees, such as onboarding expenses, monthly platform charges, and service-specific costs, can quickly spiral out of control if not addressed upfront. Leading DTC brands tackle this challenge by identifying and negotiating these fees early on, ensuring their logistics budget stays on track.

Choosing the right 3PL partner is another critical step. A dependable provider will offer a transparent breakdown of all potential costs based on your service needs and projected volume, creating a foundation for a partnership that grows alongside your business.

Tools like Forthmatch can simplify this process. By providing direct access to vetted 3PL providers without hidden markups or broker fees, Forthmatch enhances cost transparency. Features like real-time service area maps, community-driven reviews, and data-backed trust scores help eCommerce brands make well-informed logistics decisions.

Your logistics strategy directly influences customer satisfaction, operational efficiency, and profit margins. By applying what you’ve learned here - understanding pricing structures, spotting hidden fees, and using transparent comparison tools - you can fine-tune your logistics budget and build partnerships that fuel long-term success. A smart 3PL choice not only curbs hidden fees but also boosts efficiency, helping your business scale with confidence.

FAQs

What hidden fees should I watch out for in 3PL contracts, and how can I spot them before signing?

Hidden fees in 3PL contracts can sneak up on you, covering things like long-term storage fees, special handling costs for bulky or heavy items, charges for processing returns, account setup fees, and out-of-scope services that go beyond the standard agreement. If you're not paying attention, these extra costs can pile up fast.

To avoid surprises, take the time to thoroughly review the contract for mentions of additional charges outside the base rates. Request a detailed breakdown of all possible fees from your provider, and don’t hesitate to ask for clarification on any unclear terms. Negotiating these details upfront can help ensure everything is transparent and keeps unexpected costs at bay.

What factors should I consider when choosing the right 3PL pricing model for my eCommerce business?

To figure out the best 3PL pricing model for your eCommerce business, start by taking a close look at your order volume, product dimensions, and fulfillment requirements. If your business experiences consistent and predictable demand, a fixed monthly pricing model could help you save on costs. On the other hand, if your sales tend to fluctuate or are heavily influenced by seasonal trends, a pay-as-you-go model might offer the flexibility you need. For businesses requiring a mix of services, hybrid models can provide a tailored approach that suits your operations.

It's also important to factor in your storage requirements, budget constraints, and sales patterns when comparing pricing options. By understanding these elements, you can find a model that not only supports your business goals but also keeps your expenses under control.

What are the best strategies to negotiate better pricing and reduce costs with my 3PL provider?

To get better pricing and cut costs with your 3PL provider, start by focusing on your shipment volume. Many providers are willing to offer discounts if you commit to higher volumes or sign long-term contracts, making this a strong point to negotiate. Be upfront about your needs and expectations to create a win-win situation, which can help you land more agreeable terms.

You might also want to consider volume-based scaling agreements or bundling multiple services like storage, pick-and-pack, and shipping. Doing some homework on industry pricing standards can also give you an edge during negotiations. With a solid plan and open communication, you can minimize hidden fees and make the most of your logistics budget.