Outsourcing logistics to a third-party provider (3PL) can streamline operations for direct-to-consumer (DTC) brands, but it comes with risks. These challenges, if unaddressed, can disrupt inventory, inflate costs, and harm customer trust. Here's a quick rundown of the top risks and how to handle them:

- Inventory Visibility Issues: Poor tracking leads to stockouts or overstocking. Use real-time inventory tools and conduct regular audits.

- Single Provider Dependency: Relying on one 3PL can cause disruptions. Diversify providers and use multiple warehouses.

- Compliance Problems: Regulatory errors can result in fines or shipment delays. Vet 3PLs for compliance expertise and schedule audits.

- Technology Integration Failures: System mismatches cause delays and errors. Test integrations and set clear service agreements.

- Data Security Risks: Breaches can damage customer trust. Ensure your 3PL has strong cybersecurity measures and conduct regular audits.

- Poor Service Quality: Inaccurate or delayed shipments hurt your brand. Use performance reviews and set clear SLAs.

- Hidden Fees: Unexpected costs strain budgets. Demand transparent pricing and review invoices regularly.

Pro Tip: Platforms like Forthmatch can help you find reliable 3PL providers with proven tech, compliance, and cost transparency.

Logistics Risk and The Management of Logistics Risks (Logistics Risks and Logistics Risk Management)

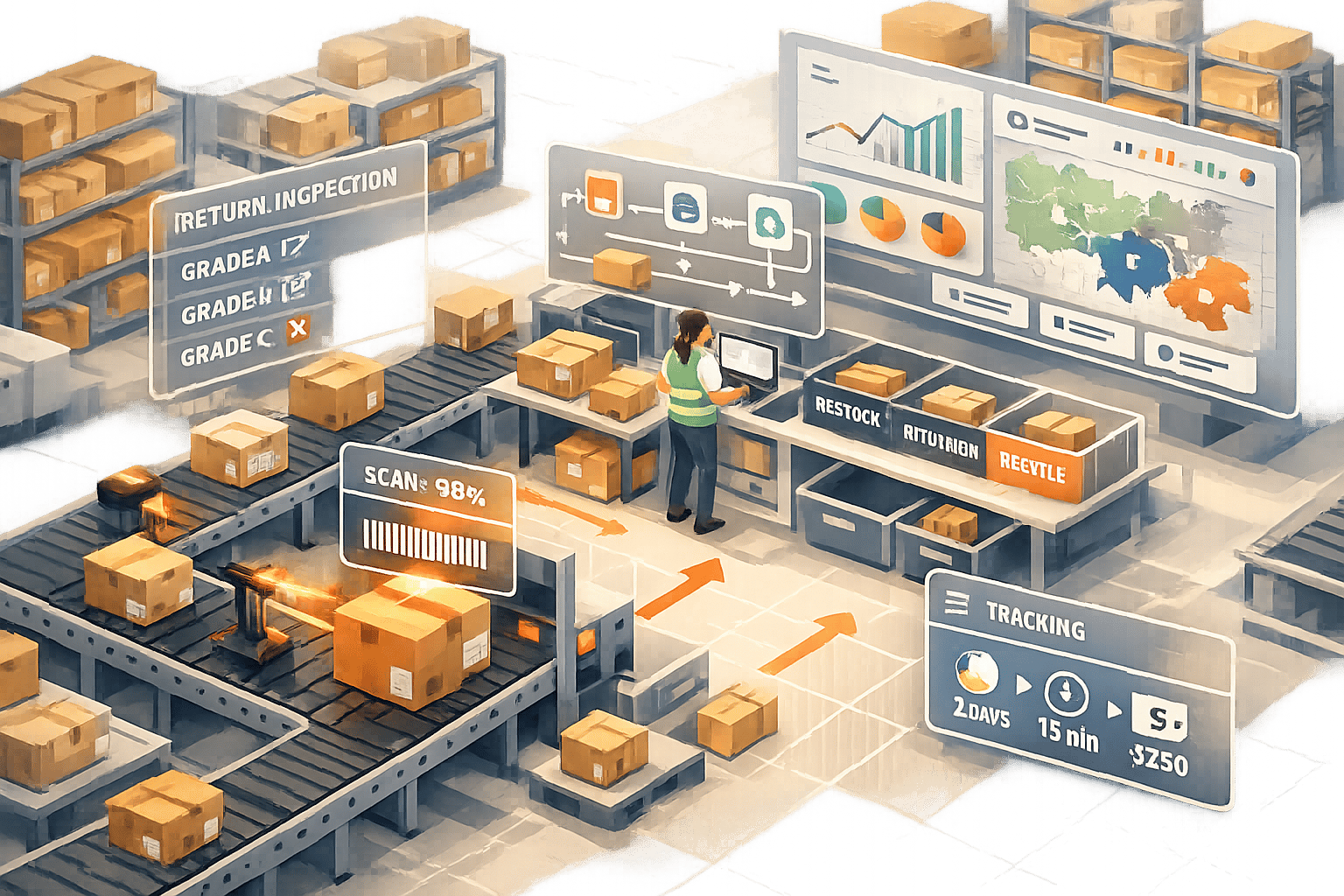

1. Poor Inventory Visibility and Control

Handing over your inventory to a 3PL provider is a big leap of trust. You're relying on them to manage your stock as if it were their own. But when inventory visibility breaks down, that trust can quickly turn into a major headache. For DTC brands, this kind of uncertainty can lead to lost customers and revenue.

Operational Impact

Without real-time inventory tracking, things can spiral fast. If your 3PL doesn’t have the right systems or fails to update stock levels accurately, you could end up overselling. And that’s a problem. Overselling means canceled orders or delayed shipments - both of which can seriously harm customer trust. On the flip side, underestimating stock can result in stockouts, leaving customers frustrated when they can’t get what they want.

This lack of visibility can also mess with your ability to plan ahead. If you can’t forecast demand or track inventory turnover, you might find yourself stuck with dead stock taking up valuable warehouse space or scrambling to place rush orders that eat into your profits. For DTC brands, which often operate with lean inventory models, these kinds of disruptions can be especially damaging.

Why It Matters for DTC Brands

DTC brands don’t have the luxury of large buffer inventories or multiple sales channels to fall back on. They run on tight margins and rely heavily on customer satisfaction to drive repeat business and word-of-mouth referrals. That’s why precise inventory control is so critical - it keeps cash flow steady and ensures you can deliver on your promises to customers.

Inventory mistakes can have an outsized impact on DTC brands. Online shoppers expect instant gratification, and if you can’t deliver, they’re quick to voice their frustrations - often on social media. Seasonal spikes and new product launches add another layer of complexity, making it even more important to know exactly how much stock you have and where it’s located.

How to Mitigate the Risks

- Use integrated inventory management tools: Choose systems that connect directly to your 3PL and eCommerce platform. Real-time dashboards or API integrations can give you a clear picture of your stock levels at all times.

- Set up clear communication protocols: Make sure your 3PL can provide accurate stock counts within hours, not days. Quick, reliable communication is key.

- Conduct regular audits: Schedule physical inventory checks and use automated alerts to catch discrepancies early. These audits can help you identify and fix any underlying issues in your 3PL’s processes.

- Build in buffer stock: A small cushion of extra inventory can help cover gaps in visibility and prevent stockouts during high-demand periods.

Tools and Best Practices to Consider

Invest in inventory management software that syncs seamlessly with both your eCommerce platform and your 3PL’s warehouse systems. A unified dashboard can help you spot discrepancies quickly and keep your inventory accurate across all channels.

Track metrics like inventory accuracy rates and stockout frequency. Automated systems can use historical sales data and lead times to trigger reorder alerts, so you’re never caught off guard.

Platforms like Forthmatch can help you find 3PL providers with proven tech integrations. Use it to filter providers based on their compatibility with major eCommerce platforms and assess their tech capabilities before signing any contracts.

Finally, keep detailed records of inventory issues. Document when problems occur, how long they take to resolve, and what caused them. This information is invaluable when negotiating service level agreements or deciding whether it’s time to switch providers.

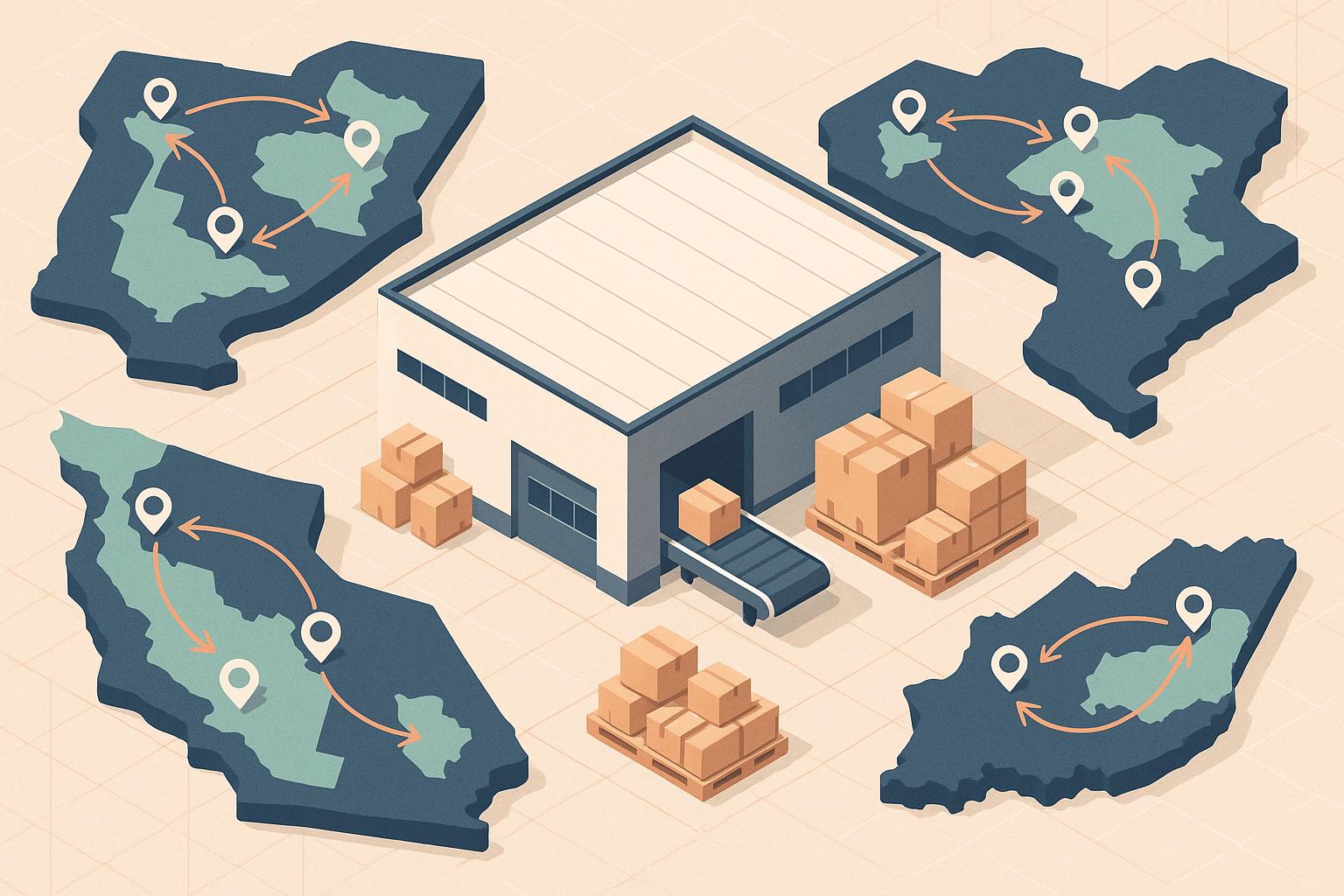

2. Relying on One 3PL Provider

Depending on a single third-party logistics (3PL) provider can leave direct-to-consumer (DTC) brands vulnerable to unexpected disruptions. If your provider encounters problems - like system failures, capacity shortages during peak seasons, or other unforeseen challenges - your entire operation could grind to a halt. And without a backup plan, you’re left scrambling to recover.

Operational Impact

When your sole 3PL provider faces issues, the ripple effects can be severe. Fulfillment delays frustrate customers, potentially damaging your brand’s reputation. According to recent data, 36% of supply chain leaders increased their reliance on 3PLs in the past year due to economic pressures. Yet, only half of these companies are actively diversifying their logistics networks to minimize such risks.

Geographic limitations can make matters worse. For instance, if your provider primarily operates in the eastern U.S., shipping to West Coast customers becomes slower and more expensive. This not only limits your ability to expand efficiently but also undermines cost optimization. For DTC brands running lean operations, these challenges can be especially damaging.

Relevance to DTC Brands

For fast-growing DTC brands, relying on a single provider amplifies risks. With 82% of executives expecting DTC growth between 10% and 25% in the next year, brands need logistics partners that can scale quickly and serve a variety of regions. A single-provider setup also limits your leverage when it comes to negotiating rates. If your provider raises prices or adds unexpected fees, your already thin margins could take a hit, making it harder to maintain competitive shipping rates.

International expansion presents another challenge. Sticking with one domestic provider can hinder global growth, especially when tariffs on imported goods range from 15% to 35% - and sometimes climb as high as 54% in certain cases. Flexible logistics strategies are essential to avoid these extra costs.

Mitigation Strategies

To reduce these risks, diversify your 3PL partnerships. Keep your primary provider for core markets, but also work with specialized partners to cover additional regions or specific needs. This approach not only improves operational flexibility but also fosters better service standards and keeps pricing competitive.

For international orders, consider bypassing U.S. logistics centers. Partner with 3PLs in key regions like Canada, Europe, the United Kingdom, Australia, and Asia-Pacific. Shipping directly from these regions can lower logistics costs and help you avoid hefty U.S.-bound tariffs.

Geographic diversification is equally important. Spread your operations across multiple warehouses, fulfillment centers, or logistics hubs. This minimizes the risk of disruptions at any single location and ensures you have backup options in place.

Actionable Tools and Practices

Leverage tools like Forthmatch to compare vetted 3PL providers based on geographic reach, platform compatibility, and service offerings - before a crisis strikes.

Start with a gradual diversification strategy. Shift a portion of your volume to a secondary 3PL and track key metrics like order accuracy, shipping speed, and customer satisfaction. Develop contingency plans that outline which provider handles specific products, regions, or order types.

You might also explore specialized partnerships. For example, one provider could focus on standard fulfillment while another handles returns processing or international shipping. Starting this process early is crucial - 34% of companies identify 3PL partnerships as a way to optimize costs, while 30% use them to strengthen their distribution networks.

3. Compliance and Regulatory Problems

For DTC brands, navigating the maze of logistics regulations can feel like walking through a minefield. If your 3PL provider isn’t keeping up with evolving compliance requirements, the fallout lands squarely on your business. Whether it’s adhering to FDA regulations for health and beauty products, managing state tax obligations, or addressing international shipping rules, non-compliance can result in hefty penalties, delayed shipments, and strained customer relationships.

Operational Impact

When compliance issues arise, the ripple effects are costly and frustrating. For instance, customs delays can leave shipments stuck for weeks, leading to unhappy customers and lost trust. On the domestic front, errors like incorrect tax calculations can prompt audits, while mishandling regulated products - such as supplements or cosmetics - can result in FDA violations or even product recalls.

The financial impact is no small matter. Penalty fees can range from hundreds to thousands of dollars per incident. But the reputational damage may be even worse. Customers affected by delayed or rejected shipments often voice their frustrations online, which can hurt future sales and tarnish your brand image.

Documentation errors only add fuel to the fire. If your 3PL provider submits incorrect paperwork for international shipments, packages can get stuck in customs limbo. This not only delays delivery but also creates extra administrative headaches, pulling your team away from growth-focused tasks. Fixing these errors is critical to avoid prolonged delays and further complications.

For DTC brands, these challenges are particularly painful. With slim margins and a direct relationship with customers, every delay or penalty chips away at both profits and trust.

Relevance to DTC Brands

DTC brands face compliance hurdles that traditional retailers often sidestep. Selling directly to consumers across multiple states triggers a patchwork of tax rules, sales permits, and consumer protection laws. Your 3PL provider needs to grasp these intricacies and stay updated as regulations shift.

Expanding internationally brings even more complexities. Each country has unique import restrictions, labeling requirements, and duty calculations. A 3PL provider unfamiliar with these rules can inadvertently cause violations, leading to seized shipments or banned products. This risk is especially high for brands dealing in consumables, electronics, or personal care items, which are subject to stricter oversight.

Product liability concerns also loom large. If your 3PL mishandles temperature-sensitive goods or fails to follow proper storage protocols for regulated items, you could face legal and regulatory consequences - even if the fault lies with them.

Mitigation Strategies

To protect your business, start by thoroughly vetting potential 3PL providers before signing any contracts. Ask for documentation of their regulatory certifications, audit results, and staff training programs. If they handle FDA-regulated products, ensure they hold Good Distribution Practice (GDP) certifications and provide evidence of regular compliance training for their teams.

Clearly outline responsibilities in your 3PL contract. Specify who is accountable for tax calculations, regulatory filings, and documentation. Include penalty clauses to hold your provider financially responsible for compliance failures. This accountability encourages them to take regulatory obligations seriously.

Regular compliance audits are another essential step. Schedule quarterly reviews of your 3PL provider’s processes, documentation practices, and any regulatory updates. This proactive approach can help identify and address issues before they escalate.

Actionable Tools and Practices

To stay ahead of compliance challenges, create and share a detailed compliance checklist with your 3PL provider. This checklist should cover all regulatory requirements relevant to your products and target markets, ensuring nothing slips through the cracks.

Platforms like Forthmatch can help you find 3PL providers with proven expertise in your industry. Use their filtering tools to locate providers experienced in areas like FDA compliance or international shipping regulations.

Establish direct communication channels with your 3PL’s compliance team to stay informed about regulatory changes. Monthly compliance reports can be a helpful tool, providing updates on new regulations, completed training, or any issues that have arisen.

Lastly, always maintain backup documentation for all regulatory requirements. While your 3PL provider should keep compliance records, having your own copies of certifications, permits, and correspondence ensures you’re prepared to address audits or compliance questions quickly and efficiently.

4. Technology Integration Problems

When your 3PL provider’s systems don’t seamlessly connect with your eCommerce platform, it can lead to a cascade of issues that hit both your bottom line and customer experience. From inventory updates failing to delays in order processing, these technical challenges can grind your operations to a halt.

Operational Impact

Poor technology integration creates immediate headaches that only get worse over time. For instance, when your 3PL’s warehouse management system doesn’t sync properly with your Shopify or WooCommerce store, you risk overselling products. This often leads to canceled orders and disappointed customers.

Delays in order processing are another frequent issue. Without smooth communication between systems, orders can get stuck in a digital limbo, sometimes for hours or even days, before they reach your 3PL’s fulfillment team. This not only slows shipping but also leads to frustrated customers reaching out for updates, creating a customer service nightmare.

When automated systems fail, your team has to step in manually - whether it’s updating inventory levels, re-entering order data, or troubleshooting sync issues. Not only is this time-consuming, but it also increases the likelihood of human error, which can cause even more disruptions.

Data visibility also takes a hit. Without real-time access to fulfillment data, you’re left guessing when it comes to inventory planning, performance tracking, and customer updates. This lack of transparency makes it tough to provide accurate delivery estimates or prevent stockouts. All of these challenges highlight the importance of aligning your eCommerce platform with your 3PL’s technology.

Relevance to DTC Brands

For DTC brands, the stakes are even higher. These businesses rely on real-time data synchronization across multiple sales channels, from their own websites to marketplaces like Amazon and social media platforms. Unlike traditional retailers, DTC brands depend on seamless integration to maintain their unique customer relationships.

When customers place orders directly on your website, they expect immediate confirmation and accurate tracking updates. Integration issues can disrupt this communication chain, eroding the trust and transparency that DTC brands work hard to build.

As DTC brands scale, integration problems can become a major bottleneck. If your 3PL uses outdated or rigid technology, it can hold you back from expanding to new sales channels or handling increased order volumes during busy seasons. This can force you into tough decisions between growth and operational stability.

Managing inventory across multiple channels adds another layer of complexity. Without proper integration, keeping inventory levels accurate across all platforms - whether products are being received, shipped, or returned - becomes nearly impossible. This can throw off your logistics and jeopardize your ability to meet customer expectations.

Mitigation Strategies

Here’s how you can tackle these challenges head-on:

- Evaluate integration capabilities upfront: Before choosing a 3PL provider, dive into their API documentation, supported platforms, and integration timelines. Don’t just take their word for it - ask for references from DTC brands with similar setups and verify their success stories.

- Set clear service level agreements (SLAs): Your contract should outline acceptable downtime limits, data sync frequencies, and response times for technical issues. Consider including financial penalties for integration failures that disrupt your operations.

- Test thoroughly before going live: Use a sandbox environment to test integrations, ideally for at least two weeks. Simulate peak traffic conditions to ensure the system can handle your actual business demands. Establish backup processes to keep orders moving during outages.

Actionable Tools and Practices

To stay ahead of integration issues, consider these tools and practices:

- Use real-time monitoring tools to track integration performance. Set up automated alerts for sync failures, API errors, or unusual delays in data transmission. This allows you to address problems before they escalate.

- Platforms like Forthmatch can help you find 3PL providers with proven experience integrating with your eCommerce platform, whether you use Shopify, WooCommerce, Amazon, or another system.

- Schedule monthly integration reviews with your 3PL. These meetings should include both technical teams and account managers to discuss system performance, address issues, and plan updates.

- Maintain detailed integration documentation covering data flows, API endpoints, error handling, and troubleshooting steps. This resource will save time when onboarding new team members or resolving technical issues quickly.

sbb-itb-eb0f906

5. Data Security and Cyber Attacks

When you work with a 3PL provider, you’re entrusting them with some of your most sensitive business data, including customer information. Unfortunately, this trust comes with risks. Cybercriminals are increasingly targeting the logistics industry, making it a hotbed for data breaches. For DTC brands, the fallout can be especially damaging.

Operational Impact

A data breach at your 3PL can grind your operations to a halt. Hackers infiltrating warehouse management systems can disrupt order processing, corrupt inventory records, and delay shipments. This kind of disruption doesn’t just affect day-to-day operations - it can also erode trust in your brand over time.

The financial consequences go beyond operational setbacks. Regulatory fines can pile up if customer payment data is compromised, and legal fees from customer lawsuits can quickly escalate. You might also need to cover the cost of credit monitoring services for affected customers.

The reputational damage can be even harder to recover from. Once word of a breach spreads, customers may hesitate to place new orders or even cancel subscriptions. Winning back their trust takes time, transparency, and consistent effort, often stretching over months or years.

Recovering from a breach isn’t quick or easy. Data recovery and system restoration can take weeks, leaving you with limited visibility into inventory, order statuses, and shipping updates. This lack of clarity can complicate customer service responses and make it difficult to provide accurate updates to your customers.

Relevance to DTC Brands

For DTC brands, the stakes are even higher. These brands often collect and store detailed customer data, such as purchase histories, personal preferences, subscription details, and even direct payment information. If this data is compromised through a 3PL breach, the damage to your brand’s reputation can be immense.

Unlike large corporations with dedicated cybersecurity teams, many DTC brands lack the resources to thoroughly vet their 3PL providers’ security measures. Often, you’re relying on the provider’s assurances without the technical know-how to verify their claims.

Adding to the complexity is the interconnected nature of DTC operations. Your 3PL likely integrates with multiple systems, such as your eCommerce platform, inventory management software, and customer service tools. A breach in one system can ripple across all connected platforms, exposing sensitive data on a larger scale.

Regulatory compliance is another challenge. Operating across different states means navigating a patchwork of data protection laws, and international shipping brings additional requirements like GDPR compliance. A single security incident could trigger investigations from multiple regulatory bodies, compounding the pressure on your business.

Mitigation Strategies

To minimize risks, start with a thorough security assessment when choosing a 3PL provider. Ask for detailed documentation of their cybersecurity protocols, including encryption standards, access controls, and incident response plans. Don’t settle for vague security certifications - demand specifics about how they protect data both in transit and at rest.

Your contract with the 3PL should clearly define their data security responsibilities. Include requirements for encryption, specify data ownership rights, and outline notification procedures for security incidents. It’s also wise to include financial penalties for breaches caused by negligence and require the 3PL to carry comprehensive cyber insurance.

Adopt data minimization practices by sharing only the customer information your 3PL needs for order fulfillment. For example, they likely don’t need access to customer payment details or full purchase histories. Segregate sensitive data into separate streams to reduce exposure.

Conduct regular security audits, ideally every quarter, to review access logs, system updates, and security protocols. For added assurance, consider hiring third-party security firms to perform penetration testing on the systems connecting your platforms with your 3PL’s infrastructure.

Actionable Tools and Practices

Invest in continuous monitoring and maintain independent backups of critical data. Cloud-based security tools can track access patterns and flag unusual activity in real time. These tools can also monitor API interactions between your eCommerce platform and your 3PL’s systems, giving you an extra layer of protection.

Platforms like Forthmatch can help you identify 3PL providers with strong security track records. Use the platform to filter providers based on their security certifications and read reviews from other merchants about their experiences with data protection.

Prepare for the worst by creating a detailed incident response plan. This plan should include steps for notifying affected parties, templates for customer communication, and coordination protocols with your 3PL’s security team. Regularly test this plan with simulated breach scenarios to ensure your team is ready to act quickly.

Finally, prioritize security training for your team members who have access to 3PL systems. Many breaches occur through social engineering attacks, such as phishing, that target employees. Ongoing education about recognizing and preventing these threats is crucial for keeping your data safe.

6. Poor Service Quality and Limited Growth Support

When your 3PL provider falls short on service or can’t scale alongside your business, it creates a bottleneck that stifles growth and strains customer relationships. Many DTC brands eventually realize their fulfillment partner lacks the infrastructure, expertise, or commitment needed to support their expansion. This issue becomes even more problematic when the provider cannot handle increasing order volumes.

Operational Impact

Subpar service can show up in ways that directly hit your bottom line. For instance, frequent shipping delays frustrate customers and lead to a spike in support inquiries. Meanwhile, inaccurate order fulfillment results in returns, exchanges, and refunds, cutting into your margins.

But the ripple effects go further. Errors in fulfillment can erode customer trust, reducing repeat purchases and lowering lifetime value. Even if the problem lies with your logistics partner, customers often associate these failures with your brand.

The inability to support growth is an even bigger hurdle. During peak seasons or after successful marketing campaigns, an unprepared 3PL can hold you back from seizing opportunities. You might have to turn down large orders or scale back marketing efforts because your provider can’t handle the demand.

Higher return rates caused by fulfillment mistakes also drive up costs. Reverse logistics, restocking fees, and additional customer service efforts add up quickly. And when you miss out on sales during peak periods, the lost revenue is hard to recover.

Relevance to DTC Brands

DTC brands face unique challenges when dealing with 3PL service quality. Unlike traditional retailers with multiple sales channels, DTC brands rely heavily on direct customer relationships and their reputation. A single fulfillment error can damage customer trust that took months or years to build.

Seasonal spikes add complexity. Many DTC brands generate a significant portion of their annual revenue during peak periods like Q4. Events such as Black Friday or the holiday season demand that your 3PL can handle volume surges. When they fail, customers often hold your brand accountable. Subscription-based brands face even higher stakes, as one bad experience can result in long-term revenue losses.

Mitigation Strategies

To address these challenges, start by setting clear service level agreements (SLAs). These agreements should outline performance standards, including order accuracy, shipping timelines, and capacity during peak periods. You can also include financial penalties for consistent underperformance.

Consider diversifying your 3PL partnerships. This doesn’t mean splitting inventory evenly but having backup providers ready to take on extra volume during disruptions.

Regular performance reviews are essential. Track metrics like order accuracy, shipping speed, inventory discrepancies, and customer complaints. During peak times, increase the frequency of these reviews to catch problems early.

Plan for growth from the start. When evaluating potential 3PL providers, discuss your expansion goals. Ask about their capacity limits, technology scalability, and experience managing higher order volumes. A provider that performs well under current demand might struggle as your needs grow.

Actionable Tools and Practices

Reliable partners are key to sustaining growth. Use monitoring tools, like those mentioned in earlier sections, to track fulfillment performance. Many eCommerce platforms include analytics that can flag issues with shipping times, return rates, or customer complaints. Setting up automated alerts for dips in key metrics can give you an early warning.

Customer feedback is another valuable resource. Pay attention to review sites, social media mentions, and customer service tickets to identify emerging fulfillment problems before they escalate.

Platforms like Forthmatch can help you find 3PL providers with proven records of supporting business growth. Their filtering tools and real-time service maps allow you to evaluate providers based on order volume and geographic needs.

Finally, have contingency plans in place. Prepare for scenarios like peak season overflows, quality issues, and emergencies by negotiating agreements with backup 3PLs. Regular site visits - virtual or in person - can also provide insights into your provider’s operations, including their organization, technology use, and staff training. These proactive steps can make all the difference when challenges arise.

7. Unexpected Costs and Hidden Fees

Hidden fees from 3PL providers can eat into profit margins and throw off your financial plans. For many DTC brands, these charges often come as a surprise, stemming from unclear pricing or undisclosed surcharges.

Operational Impact

When unexpected fees show up, they can wreak havoc on your cash flow and force you to rethink your budget. A sudden spike in your monthly 3PL bill might leave you scrambling to adjust other expenses. Worse, these surprises might push you to raise product prices mid-season, which could alienate customers. On the flip side, absorbing the costs might mean cutting back on marketing or product development - both of which are essential for growth.

Some common culprits include storage overage fees, adjustments for dimensional weight pricing, peak season surcharges, and extra charges for inventory receiving, returns processing, or special packaging. These fees often appear vaguely described on invoices, making it hard to figure out exactly what you're paying for. Staying ahead of these surprises requires proactive oversight.

Relevance to DTC Brands

DTC brands are especially vulnerable to hidden 3PL costs. Unlike larger retailers with teams dedicated to procurement and contract negotiation, smaller DTC brands often lack the resources to spot potential fee traps or negotiate better terms.

Seasonal businesses face even greater risks. For example, a skincare brand might get hit with unexpected peak season surcharges during its busiest sales period. Similarly, subscription box companies could be blindsided by fees for handling returns or managing fluctuating inventory levels.

Smaller order volumes, a hallmark of many DTC brands, can also mean less negotiating power with 3PL providers. This often results in less favorable contracts and fewer opportunities to challenge questionable fees.

Mitigation Strategies

To avoid these pitfalls, start by demanding full transparency during the evaluation phase. Ask potential 3PL partners for a detailed list of all possible fees and request sample invoices (with sensitive details removed) to see how charges are typically itemized.

Consider negotiating fee caps or opting for flat-rate pricing to make budgeting more predictable. Some providers may agree to cap variable costs like storage fees, giving you more control over your expenses.

Clearly outline service level agreements (SLAs) that specify base pricing and define when additional fees might apply. Include a clause requiring advance notice - 30 to 60 days - before any new fees or rate changes take effect.

It can also be wise to build relationships with multiple 3PL providers. Even if you don’t split your inventory, having a backup option gives you leverage in negotiations and an alternative if your primary provider introduces unreasonable charges.

Actionable Tools and Practices

Regularly audit your invoices using a tracking spreadsheet, and set up automated alerts in your accounting software to flag unexpected fee spikes. A simple month-over-month tracking sheet can help you quickly identify unusual charges.

Before signing any 3PL contract, use a review checklist to ensure key terms are clear. Focus on areas like storage fee calculations, handling charge structures, peak season policies, termination terms, and limits on fee increases. Having a lawyer review significant contracts can also save you headaches down the line.

Platforms like Forthmatch can help you avoid broker markups and hidden fees by connecting you directly with vetted 3PL providers. Their transparent directory makes it easier to compare pricing structures without worrying about inflated rates.

Keep detailed records of fee agreements, including email confirmations of any verbal pricing promises. Set up quarterly reviews with your 3PL provider to address fee concerns early, and ensure you’re not caught off guard by new charges. These proactive steps can go a long way in safeguarding your bottom line.

Risk and Solution Summary Table

Here’s a handy overview of common 3PL risks, their potential business impacts, and practical solutions to address them.

| Risk | Business Impact | Primary Solutions | Tools & Practices |

|---|---|---|---|

| Poor Inventory Visibility | Stock-outs, overstocking, unhappy customers, and lost sales | Implement real-time tracking, automated alerts, and integrated systems | Use WMS integration, set automated reorder points, and generate daily inventory reports |

| Single 3PL Dependency | Service disruptions, reduced negotiating power, and operational risks | Work with multiple providers, establish backup partnerships, and distribute operations geographically | Adopt a multi-provider strategy, create contingency plans, and use regional fulfillment centers |

| Compliance Issues | Fines, shipment delays, regulatory problems, and restricted market access | Partner with compliant 3PLs, conduct regular audits, and follow strict documentation protocols | Leverage industry certifications, customs expertise, and regulatory training programs |

| Technology Integration Problems | Delays in order processing, data errors, reliance on manual fixes, and inefficiencies | Ensure API compatibility, use phased integration, and have dedicated IT support | Utilize platform-specific integrations, testing environments, and technical documentation |

| Data Security Risks | Breaches of customer data, financial losses, reputation damage, and legal issues | Conduct security audits, apply encryption, enforce access controls, and create incident response plans | Focus on SOC 2 compliance, regular penetration testing, and maintaining reliable data backups |

| Poor Service Quality | Late shipments, damaged goods, customer complaints, and harm to brand reputation | Use SLA agreements, monitor performance, and enforce quality control measures | Track KPIs, gather customer feedback, and schedule regular performance reviews |

| Hidden Fees | Budget overruns, cash flow challenges, reduced profits, and disrupted financial planning | Demand transparent pricing, set fee caps, and include advance notice clauses in contracts | Audit invoices, track costs with spreadsheets, and review contracts thoroughly |

For a streamlined approach, try Forthmatch to find vetted 3PL providers. They offer transparent pricing and direct communication, helping you focus on key areas like inventory visibility and service quality. Regularly assess your 3PL partnerships and keep an eye on KPIs to stay ahead of potential challenges.

Conclusion

Partnering with a 3PL can fuel growth for DTC brands, but the risks we've outlined - like inventory visibility issues leading to stock shortages or hidden fees inflating costs - can create serious challenges if not managed properly. Addressing these concerns requires careful planning and thoughtful selection of your logistics partner.

Success starts with thorough preparation and research. Before committing to any 3PL, take time to evaluate potential partners, outline clear service level agreements, and develop contingency plans for essential operations. Setting up monitoring systems, maintaining diverse provider relationships, and conducting regular performance reviews can help you stay ahead of potential problems.

In today’s tech-driven world, technology integration and data security are especially critical. Make sure your 3PL can seamlessly integrate with your existing systems and has strong cybersecurity measures in place. These upfront investments can save your business from costly disruptions down the line.

To simplify the process, platforms like Forthmatch offer a streamlined way to connect with vetted 3PL providers. With tools like real-time service area maps and feature-based filters, you can quickly find partners that align with your needs - without worrying about broker fees or hidden costs. Plus, direct contact options let you negotiate terms without intermediaries driving up expenses.

FAQs

What are the best ways to ensure smooth technology integration with a 3PL provider?

To make technology integration with a 3PL provider as smooth as possible, start by focusing on open and clear communication. Work with your provider to define shared KPIs that promote transparency and ensure both parties are aligned on goals. Pinpoint critical integration points, such as order management, inventory updates, and shipping notifications, to ensure data flows smoothly and avoids any hiccups.

Take a close look at the provider’s tech capabilities. This includes features like real-time tracking, warehouse management systems, and tools that enhance supply chain visibility. Choose a provider whose systems align well with your existing platforms and who offers strong onboarding support and troubleshooting assistance. These steps can help simplify the integration process and boost your operational efficiency.

How can DTC brands protect sensitive data when partnering with a 3PL provider?

When collaborating with a 3PL provider, protecting sensitive data should be a top priority for DTC brands. Look for providers that have strong cybersecurity protocols in place. This means they should conduct regular security audits, use encryption to safeguard data, and have a clear incident response plan ready in case of a breach.

It's also crucial to verify that the 3PL complies with data protection laws like the CCPA and GDPR, even if your business mainly operates in the U.S. Taking the time to review their security measures and performing your own risk assessments can add an extra layer of protection for your supply chain and customer data.

Addressing these security concerns upfront helps reduce risks and ensures a safer, more reliable partnership with your 3PL provider.

How can I avoid unexpected costs and hidden fees when working with a 3PL provider?

To steer clear of surprise expenses and hidden charges when working with a 3PL provider, start by thoroughly examining their pricing structure and contract terms. Ask for a detailed breakdown of all possible fees, such as storage, labor, handling, and any additional surcharges. Requesting a sample invoice can also give you a clearer picture of potential hidden costs.

Keep communication lines open with your provider and make sure all agreements are well-documented. It's also a good idea to periodically review the contract for clauses that might lead to extra charges down the line. Taking these steps and focusing on transparency can help you keep your logistics budget in check and avoid unexpected financial headaches.