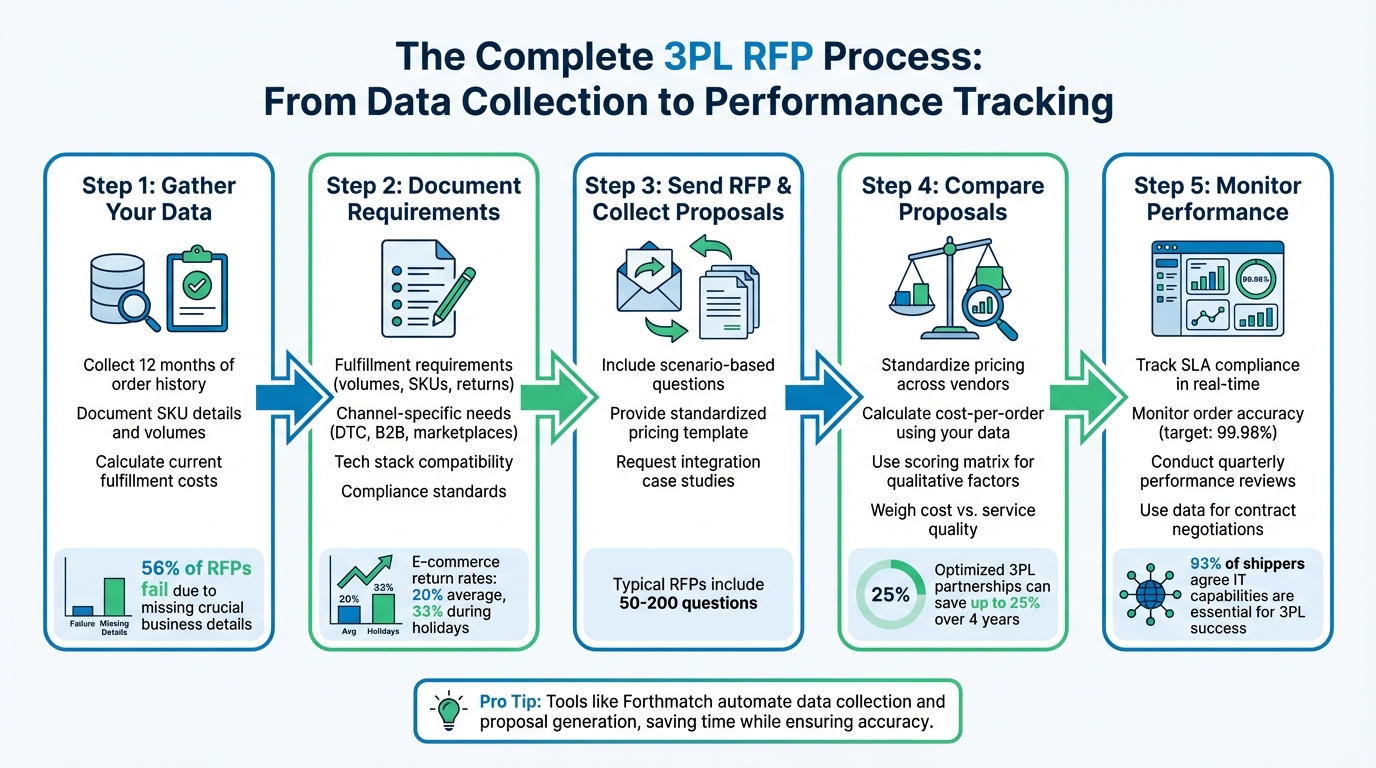

Choosing the right third-party logistics (3PL) provider can save you money, improve fulfillment, and enhance customer satisfaction. An RFP (Request for Proposal) is a structured process that helps you evaluate 3PLs based on your specific needs, ensuring clear pricing and service commitments. Here's what you need to know:

- Why RFPs Matter: They eliminate vague sales pitches and ensure providers align with your business needs.

- Key Steps: Include detailed data on order volumes, SKUs, shipping requirements, and tech integrations. Use scenario-based questions to assess scalability.

- What to Include: Fulfillment requirements, channel-specific needs (DTC, B2B, marketplaces), tech stack compatibility, compliance standards, and performance metrics.

- Evaluating Proposals: Standardize pricing comparisons and weigh cost against service quality, tech capabilities, scalability, and support.

- After Selection: Monitor performance with clear SLAs and regular reviews to ensure accountability and continuous improvement.

Pro Tip: Tools like Forthmatch make the RFP process easier by automating data collection and proposal generation, saving time while ensuring accuracy.

A well-crafted RFP ensures you find a 3PL partner who meets your needs while reducing costs and avoiding surprises.

5-Step RFP Process for Selecting the Right 3PL Provider

Simplifying the 3PL RFP Process with Slotted

What to Include in Your 3PL RFP

When crafting a Request for Proposal (RFP) for a third-party logistics (3PL) provider, the details you include can make or break the process. A well-structured RFP ensures you're comparing apples to apples, helping you avoid vague pitches and hidden costs. The secret? Specificity. The more precise your requirements, the more accurate and reliable the proposals you'll receive.

"The better your RFP, the better your results. Accurate pricing, efficient onboarding, reliable service - these all start with how you define the job" - PiVAL

Your RFP should focus on five critical areas: operational data, sales channel needs, technical integrations, compliance standards, and performance expectations. For example, instead of saying "we ship a lot of orders", specify "we process an average of 2,500 orders per month, with peaks of 4,000 in Q4." This level of detail helps you avoid misaligned partnerships and ensures you get tailored proposals.

Document Your Fulfillment Requirements

Start by laying out your operational needs. Include key metrics like average and peak order volumes, the number of SKUs, and product details (e.g., weight, dimensions, fragility, or temperature requirements). For instance, e-commerce businesses often face return rates as high as 33% after the holidays - be sure to outline your returns process, whether it involves restocking, disposal, or quarantining.

Break your requirements down by sales channel. Direct-to-Consumer (DTC) orders, B2B shipments, and marketplace platforms like Amazon or Walmart each have unique demands:

- DTC: Focus on fast, accurate order fulfillment.

- B2B: Specify EDI capabilities, retail compliance labeling, and pallet standards.

- Marketplaces: Ensure the 3PL can meet strict fulfillment SLAs to avoid penalties or account suspensions.

To gauge a provider's capabilities, include scenario-based questions. For example, ask how they would handle a 40% surge in order volume within 72 hours. This approach highlights their ability to scale and adapt. Additionally, provide a standardized pricing template covering storage fees, inbound processing, pick-and-pack rates, and extra services like kitting or custom inserts. This ensures you can easily compare costs across vendors.

Specify Integration and Compliance Requirements

Technology compatibility is critical. A mismatch here can lead to delays, failed integrations, and unexpected costs. Clearly list your tech stack - from storefronts like Shopify or BigCommerce to ERPs like NetSuite or SAP and marketplaces such as Amazon or eBay. Don’t forget tools for customer experience, like Loop or AfterShip.

"If your systems don't connect, your supply chain doesn't function. A vague description of your tech stack leads to integration delays, failed EDI tests, or expensive custom work" - PiVAL

Outline your data exchange protocols. Specify whether you need EDI capabilities, preferred EDI partners (e.g., SPS Commerce), or APIs for custom integrations. For B2B operations, include detailed compliance requirements like GS1-128 labeling, lot tracking, expiration date management, and certifications such as GMP or GFSI. Additionally, address data security standards, specifying compliance with GDPR or CCPA, and clarify liability in the event of a data breach.

Ask for integration case studies from prospective 3PLs. Look for examples where they've successfully worked with clients using a similar tech stack (e.g., Shopify and NetSuite). It's also wise to involve your IT team early in the RFP process to ensure all technical and data requirements are accurately captured.

Define Your Performance Metrics and SLAs

Setting clear performance metrics ensures accountability. Start with expectations for order fulfillment speed - define "Average Days to Fulfill" (from order import to labeling) and "Average Days in Transit" (from label purchase to delivery).

"Brands like Our Place reduced fulfillment speeds from 5–6 days down to 2.5 days by utilizing distributed fulfillment networks" - Flowspace

Establish accuracy benchmarks. Top-tier providers often aim for 99.98% order accuracy. Include additional metrics such as shrinkage limits, damage rates, and inventory count frequency. For example, set a maximum dock-to-stock time - like 48 hours from warehouse arrival to inventory availability.

To standardize your evaluation, provide pre-built tables for 3PLs to input their KPI data. Define audit schedules, such as quarterly physical inventory counts or daily inventory snapshots, to ensure accountability. Lastly, outline specific Service Level Agreements (SLAs) for support, such as requiring a 30-minute response time for urgent issues. Be explicit about penalties or remedies if the 3PL fails to meet agreed-upon standards.

Gather Your Data Before Sending the RFP

Before sending out an RFP, it's essential to have a solid understanding of your own operations. If your data is incomplete or inaccurate, 3PLs are left guessing, which leads to vague proposals, unexpected costs, and potential service issues down the road.

"If your RFP doesn't reflect your operations properly, the proposals you receive won't either. This has a direct effect on service failures, missed KPIs, and inflated costs down the line." - PiVAL

This issue is more common than you might think. 56% of RFPs fail to include crucial details about business goals, growth plans, and expectations for the partnership. Without concrete numbers, 3PLs struggle to determine the appropriate warehouse space, staffing, or technology needs. Instead, they often provide "price-only" proposals, which may later include hidden fees once the full scope of work becomes clear. To avoid this, it's crucial to conduct a thorough internal review before drafting your RFP.

Collect Your Fulfillment History

Accurate data is the backbone of an effective RFP. Start by gathering 12 months of order data, including average monthly order volumes, daily order counts, and figures for seasonal peaks or promotional surges. For example, if your typical month averages 2,500 orders but spikes to 4,000 in November, that 60% increase highlights the need for scalable labor and storage solutions.

Document SKU details such as quantities, dimensions, weights, and any special handling requirements like lot tracking, expiration dates, or temperature control. Analyze your geographic distribution to help 3PLs recommend warehouse locations that align with your customer base. Also, break down your volume by sales channel - whether it's Direct-to-Consumer (DTC), B2B wholesale, or marketplaces like Amazon or Walmart - since each channel has unique operational demands that impact pricing and infrastructure.

Set performance benchmarks based on current metrics, such as order accuracy, inventory accuracy, shrinkage rates, receiving turnaround times, and fulfillment speeds. If you use Shopify, tools like Forthmatch can automatically pull up to 90 days of historical data, including shipping times and delays. This kind of insight is invaluable for assessing whether a new 3PL can genuinely improve your operations. Don't forget to document your returns data - e-commerce businesses typically face a 20% return rate, which can climb to 33% during the holiday season.

This historical data not only helps you understand your current fulfillment costs but also ensures that 3PL proposals are tailored to your actual needs.

Calculate Your Current Fulfillment Costs

Knowing what you're spending today is key to evaluating whether a 3PL's proposal offers real savings or simply shifts expenses around. Break down your total cost per order into categories like storage fees, inbound receiving, picking and packing, packaging materials, and outbound shipping. Be sure to factor in hidden costs, such as insurance, cancellation fees, and account management charges.

"Accurate historical volumes, peaks, inventory detail and more enable prospective 3PLs to build pricing models sans speculative assumptions that can necessitate future escalations." - Jamie C. Winters, Falcon Fulfillment

Use your current cost structure as a baseline to compare 3PL bids across different volume tiers - low, medium, and peak seasons. Providing 3PLs with a standardized pricing template ensures every proposal breaks down costs in the same way, making it easier to spot hidden fees or unrealistic minimums that don't align with your actual shipping profile.

sbb-itb-eb0f906

How to Compare 3PL Proposals

Once you've gathered responses from multiple 3PL providers, it's time to dive into the evaluation process. Typically, RFPs include anywhere from 50 to 200 detailed questions, which means you'll be sifting through proposals that vary in format, pricing, and service commitments. To make a fair comparison, you need a structured approach - one that considers not just costs but also the provider's ability to support your business as it scales. Let’s break this down, starting with standardizing pricing and then balancing cost against service quality.

Standardize Pricing for Accurate Comparison

One of the biggest challenges in comparing 3PL proposals is the inconsistency in how costs are presented. For instance, one provider might bundle pick-and-pack fees, while another separates them into a base order fee and per-unit charges. Without a consistent framework, it’s easy to miss hidden fees or misunderstand the true cost.

To address this, create a pricing template that all 3PLs must complete. This forces them to break down their costs into specific components, making it easier to see where one provider might excel in storage costs but fall short in fulfillment charges.

From there, calculate the cost-per-order using your historical data. Apply each provider’s pricing to your actual order volumes - whether it’s your average monthly shipments or peak-season spikes. For example, if you typically ship 2,500 orders a month but hit 4,000 during November, use both scenarios to see how each provider performs. This analysis will help you identify which 3PL offers better rates as your business grows and which might become too expensive during busy periods. Don’t forget to include accessorial charges like account management fees, packaging costs, peak season surcharges, and fuel adjustments.

| Pricing Component | What to Standardize | Why It Matters |

|---|---|---|

| Storage | Cost per cubic foot or pallet per month | Helps compare costs for slow-moving vs. fast-moving inventory |

| Fulfillment | Base order fee + per-unit fee | Highlights efficiency for multi-item orders |

| Shipping | Zone-based rates for specific weights | Reveals geographic advantages of the 3PL's network |

| Accessorials | Flat fee per service (e.g., kitting, inserts) | Identifies hidden fees that could increase your total spend |

Once you’ve nailed down the pricing details, it’s time to assess the service quality each provider offers.

Weigh Price Against Service Quality

While accurate pricing is essential, it’s only part of the equation. The cheapest option might not always be the best. Low-cost providers often skimp on crucial areas like technology, staffing, or warehouse capacity, which can lead to missed SLAs, inventory errors, and costly renegotiations down the line. In fact, 56% of RFPs fail to include context about business goals, growth plans, or long-term vision. This lack of detail often results in decisions based solely on the lowest bid - which can be a costly mistake.

To avoid this, use a scoring matrix to evaluate both quantitative and qualitative factors. Consider the following criteria:

- Cost efficiency: Cost-per-order and shipping zone savings.

- Speed and reliability: Average fulfillment time and order accuracy rates.

- Technology capabilities: Integration with WMS/OMS systems and real-time tracking features.

- Scalability: Ability to handle seasonal spikes without compromising service.

- Customer support: Response times and availability of dedicated account managers.

This approach allows you to identify the provider that offers the best overall value - not just the lowest price.

"The integration of cutting-edge technology in 3PL operations is no longer a luxury - it's a necessity for staying competitive in today's fast-paced logistics landscape."

- John Langley, Professor of Supply Chain Management at Penn State University

Pay close attention to Service Level Agreements (SLAs). Specific commitments like "ship within 24 hours" or "99.5% order accuracy" are far more reliable than vague promises such as "fast fulfillment" or "reliable service". These details give you a clear picture of what to expect from the provider.

Finally, reach out to references - especially those in your industry. Ask about the 3PL’s responsiveness, billing practices, and ability to scale during peak seasons. If you’re using Shopify, tools like Forthmatch can simplify this process. For $44 per request, their RFP Quote Request feature automates proposal generation using your actual order data, ensuring all 3PLs respond to the same set of requirements. This can save time and help you set realistic expectations for your next partnership.

Track Performance After You Choose a 3PL

Once you've selected a 3PL using a data-driven RFP process, the real work begins: ensuring they deliver on their promises. Signing the contract is just the start - your 3PL must consistently meet the service levels you've agreed upon. Without consistent monitoring, you might not notice performance issues until customer complaints pile up. That's why setting up real-time performance tracking is crucial to keeping your 3PL accountable.

Monitor SLA Compliance

Keep an eye on your key metrics, like order accuracy, fulfillment speed, and on-time shipping rates. Industry research shows that 93% of shippers and 99% of 3PL providers agree that strong IT capabilities are essential for 3PL success. Using technology to track these metrics is far more efficient than relying on manual methods like spreadsheets.

Tools like Forthmatch simplify this process. It analyzes up to 90 days of order history and measures the time from order placement to fulfillment. You can set specific SLA goals, such as "ship orders within 24 hours", and the platform will immediately flag any breaches. For example, instead of vague concerns like "shipping seems slow", Forthmatch might reveal that 15% of orders missed the 24-hour SLA last week. It also identifies the root causes of delays, helping you pinpoint whether issues stem from the warehouse or the carrier.

Keeping a detailed record of SLA breaches is equally important. Forthmatch makes this easy by allowing you to send one-click email alerts to your 3PL's account manager whenever an order falls short. This ongoing tracking creates a solid foundation for performance reviews.

Use Performance Reports for Contract Reviews

Real-time tracking is just one piece of the puzzle; performance reports are essential for driving accountability and identifying cost-saving opportunities. Objective data strengthens your position during quarterly reviews and contract renegotiations. For instance, if your 3PL routinely misses the 24-hour fulfillment target on Fridays, you can use the data to push for operational changes or request service credits.

Forthmatch's Accountability Session feature, available for $89 per session, is specifically designed for this purpose. Over a 2–4 week period, it tracks performance, compares "before and after" results, and generates a detailed PDF report. This report is invaluable for assessing whether improvements were made. It's worth noting that 3PLs using advanced analytics have reported a 15% boost in operational efficiency.

When reviewing performance, make sure to separate fulfillment time from transit time. This distinction ensures you're holding the 3PL responsible for their internal processes rather than external factors like carrier delays. If they frequently blame carriers for slow delivery, the data will clarify whether the real issue lies with their fulfillment process.

"The most successful 3PLs are those that can offer a comprehensive, integrated technology solution that not only manages day-to-day operations but also provides actionable insights for continuous improvement".

Conclusion

A well-thought-out RFP can significantly reduce multi-channel fulfillment costs while improving service quality. By inviting multiple proposals, you create more room for negotiation, giving you a stronger position to secure favorable terms. The detailed cost breakdowns required in an RFP also make it easier to compare expenses transparently, enabling smarter, data-driven decisions. In fact, optimized partnerships with 3PL providers can lead to savings of up to 25% over a four-year period without sacrificing service quality.

The key to success lies in using accurate data at every step. From gathering precise order volumes and SKU counts to standardizing pricing comparisons and tracking performance after signing the contract, data ensures your decisions are based on facts - not guesswork.

For Shopify merchants, tools like Forthmatch simplify this process. The platform helps you compile historical fulfillment data for your RFP, monitor whether your chosen 3PL meets SLA commitments, and even automate RFP quote requests - all for just $44. Additionally, the $19/month Performance Insights plan (which includes a 14-day free trial) offers ongoing analytics to keep your 3PL accountable and ensure your fulfillment strategy stays on track.

FAQs

How can I create a detailed RFP for a 3PL to avoid unexpected costs?

To avoid surprise expenses, your RFP should lay out every detail of your logistics needs. Be specific - include order volumes, SKU details, delivery speed expectations, and accuracy goals. Clearly communicate your operational requirements and ask for a full pricing breakdown. This should cover storage fees, pick and pack charges, shipping surcharges, and any extra costs like setup fees or penalties.

It's also a good idea to request details on contract terms, performance metrics, and any penalty clauses. This ensures the agreement aligns with your expectations. Tools like Forthmatch can be incredibly useful for tracking 3PL performance and spotting SLA compliance issues. The data these tools provide can strengthen your position during negotiations. A well-prepared and detailed RFP not only helps you manage costs but also ensures you find a 3PL partner whose services align with your business objectives.

What performance metrics should I monitor after choosing a 3PL provider?

After choosing a 3PL provider, keeping an eye on critical performance metrics is a must to ensure they align with your business goals. Start by monitoring order accuracy - shoot for at least 99.9% to reduce mistakes - and on-time shipping rates, with a target of 98% or higher, to maintain customer satisfaction.

These numbers give you a solid understanding of your 3PL's dependability and highlight any areas that may need adjustments or renegotiation.

How can technology make the RFP process for selecting a 3PL more efficient?

Technology has reshaped the way businesses manage the RFP (Request for Proposal) process when selecting a third-party logistics (3PL) provider. By automating critical steps and offering data-based insights, digital tools make the process more efficient and accurate.

For starters, these tools help businesses create standardized and detailed RFPs. This ensures logistics needs and evaluation criteria are clearly outlined, making it easier for providers to submit precise responses. Platforms like Forthmatch take it a step further by enabling performance tracking. They convert subjective feedback into measurable data, such as shipping times and SLA (Service Level Agreement) compliance, giving businesses a clearer picture of provider performance.

Automation also reduces the manual workload. Businesses can send RFPs to multiple providers simultaneously, with all responses neatly organized for straightforward comparison. This speeds up the decision-making process and ensures transparency. Ultimately, these advancements help companies find a 3PL that matches their specific operational needs, paving the way for better partnerships and improved fulfillment operations.