Reverse logistics is all about managing product returns, exchanges, repairs, recycling, and disposal. For direct-to-consumer (DTC) brands, this process is crucial to maintaining profitability and customer satisfaction. Here's the deal:

- Challenges: High return rates in eCommerce, operational costs, and customer dissatisfaction can hurt your bottom line. Returns for items like perishable goods or fragile products can lead to significant losses.

- Solution: Partnering with third-party logistics providers (3PLs) can simplify returns. They handle inspections, restocking, refurbishment, recycling, and disposal, ensuring efficiency and better customer experiences.

- Technology: Tools like Returns Management Systems (RMS) and Warehouse Management Systems (WMS) automate workflows, track inventory, and improve decision-making. Data analytics reveal return trends, help reduce costs, and enhance customer loyalty.

- Customer Communication: Clear return policies and automated updates keep customers informed, reducing frustration and boosting trust.

- Choosing a 3PL: Look for geographic coverage, tech integration, expertise in returns, cost transparency, and compliance with disposal regulations. Platforms like Forthmatch can help you find the right 3PL.

Reverse logistics isn't just about managing returns - it's an opportunity to recover value and build customer loyalty. By leveraging 3PLs and technology, brands can turn returns into a competitive advantage.

Reverse Logistics Explained

Core 3PL Reverse Logistics Services

Third-party logistics providers (3PLs) take the hassle out of handling product returns by managing tasks like inspections, restocking, refurbishment, and disposal. These processes set the stage for the advanced technology solutions we'll explore later.

Returns Processing and Inspection

When items are returned, 3PLs receive them at specialized facilities where each product is checked against return authorizations and undergoes a thorough quality inspection. This step involves assessing for damage, missing parts, or signs of use, which helps determine whether the item should be resold, cleaned, refurbished, or discarded.

By taking a structured approach to inspections, brands can make smarter decisions about returned items instead of simply writing them off as losses. Tools like barcode scanning and real-time updates ensure accurate tracking and create a reliable audit trail for every product.

Restocking, Refurbishment, and Recycling

Once inspected, returned items are sorted based on their condition and the brand’s specific guidelines. Items in perfect shape are cleaned, repackaged if needed, and restocked quickly to re-enter the inventory for sale.

For products requiring minor fixes, 3PLs may handle refurbishment directly or collaborate with specialized partners. This might involve replacing missing parts or addressing small defects, making these items ready for resale at competitive prices while still generating revenue.

If an item can’t be resold or refurbished, it’s sent to recycling programs. Here, 3PLs partner with certified recyclers to recover valuable materials like metals, plastics, or electronic components. By processing returns efficiently, 3PLs not only help brands recover sellable goods but also reduce waste and cut costs.

Disposal and Environmental Compliance

For items that are beyond recovery, 3PLs ensure proper disposal in line with environmental regulations. This is especially critical for products like electronics, batteries, or cosmetics, which often have strict disposal requirements. By adhering to federal, state, and local rules, 3PLs manage hazardous materials responsibly and maintain detailed disposal records. This careful handling of non-recoverable items supports better returns management while staying environmentally conscious.

Technology Solutions for 3PL Reverse Logistics

Today’s 3PL providers depend heavily on technology to simplify and automate the complex processes involved in reverse logistics. Key tools like Returns Management Systems (RMS), Warehouse Management Systems (WMS), and data analytics work together to track returned items, streamline decision-making, and deliver the visibility brands need to refine their operations.

Returns Management Systems (RMS)

At the heart of returns processing, Returns Management Systems automate workflows to handle customer returns efficiently. From verifying purchase details to generating tracking codes, RMS platforms connect with e-commerce systems like Shopify, WooCommerce, and Magento to pull customer and order data seamlessly. This integration reduces manual input, cutting down on errors that could delay refunds or exchanges.

RMS platforms also update inventory in real time as items move through inspection, sorting, and final disposition. Automation extends to decisions about what happens next - whether an item gets restocked, refurbished, or disposed of - based on its condition and the brand’s specific guidelines.

While RMS handles the digital side, Warehouse Management Systems ensure the physical processes stay just as efficient.

Warehouse Management Systems (WMS)

Warehouse Management Systems manage the physical flow of returned items within 3PL facilities. By working in sync with RMS platforms, WMS ensures that every returned product is received, inspected, and processed according to established workflows.

These systems provide real-time inventory updates, giving brands precise visibility into where their returned products are and when they’ll be ready for resale. This transparency is especially important for managing inventory and cash flow, particularly for fast-moving or seasonal items.

WMS platforms also integrate with e-commerce systems, ensuring inventory levels across all sales channels are updated automatically. For instance, when a returned item is approved for restocking, the WMS adjusts inventory to prevent overselling and ensure availability. Tools like barcode scanning and RFID tracking add another layer of accuracy, offering detailed insights into every step of the returns process.

The data gathered by RMS and WMS platforms becomes even more powerful when paired with analytics.

Data Analytics for Process Improvement

Data analytics transforms return data into insights that help improve operations. With reverse logistics becoming a nearly $1 trillion industry, analytics is essential for staying competitive.

By analyzing return patterns, brands can identify high-return products and seasonal trends, which informs decisions about product quality and inventory planning. For example, if a product consistently sees high return rates, it might signal a packaging issue or a need for better quality control.

Analytics also give 3PLs a complete view of the reverse logistics process - from the reasons behind customer returns to how items are sorted, reintegrated into inventory, or disposed of. This level of insight helps pinpoint inefficiencies, like bottlenecks in sorting or staffing shortfalls during busy return periods.

Cost reduction is another major advantage. By studying return shipping routes and delivery patterns, 3PLs can often combine return shipments with last-mile deliveries, cutting transportation costs. GPS data and transportation management systems further optimize routes and resource allocation.

Customer satisfaction improves as well. With 86% of customers carefully reviewing a business’s return policy before making a purchase, eliminating delays in returns processing can lead to faster refunds or replacements. This smoother experience encourages loyalty and repeat business.

Finally, analytics support sustainability efforts. By identifying products with consistently high return rates, brands can address quality issues that reduce unnecessary shipments and waste. This aligns with growing consumer demand for more eco-friendly practices while also improving operational efficiency.

sbb-itb-eb0f906

Customer Communication in Returns Management

Handling returns is one of those moments that can either build or break trust with your customers. When someone decides to return a product, they’re often feeling disappointed or frustrated. How a third-party logistics (3PL) provider manages communication during this critical time can play a huge role in maintaining - or even strengthening - customer loyalty.

Modern 3PLs understand this and focus on providing clear, timely updates throughout the returns process. By doing so, they create a seamless connection between operational efficiency and customer satisfaction.

Clear Returns Policies

A well-defined returns policy is the cornerstone of effective communication. The best policies eliminate confusion by outlining specific details like timeframes, condition requirements, and refund methods. For example, instead of vague terms like "items must be in good condition", successful policies spell out what that means - such as requiring original packaging, attached tags, or no visible signs of wear.

3PLs bring their expertise to help brands find the right balance: policies that are generous enough to reassure customers but firm enough to prevent misuse. Their operational knowledge ensures these policies are as practical as they are customer-friendly.

Accessibility is key when it comes to these policies. Top 3PLs ensure they’re easy to find - whether on product pages, in order confirmation emails, or as inserts in the packaging. Since many customers initiate returns on their smartphones, mobile-friendly policy pages are a must.

The language used in these policies also matters. Complicated legal or technical terms might make sense to lawyers, but they often confuse customers. Experienced 3PLs help brands simplify language, translating complex rules into plain, easy-to-follow instructions.

By setting clear expectations upfront, brands can maintain customer trust throughout the returns process.

Automated Updates and Refunds

Beyond having clear policies, automation takes communication to the next level, turning what could be a frustrating process into a smoother, even positive, experience.

Real-time updates start as soon as a customer initiates a return. Automated messages confirm receipt of the return request, provide shipping labels, and outline processing timelines. As items move through the stages of inspection and sorting, customers are kept in the loop with updates about their return’s progress.

Advanced 3PLs go a step further, offering detailed tracking from the moment a return is received at the warehouse to the time a refund is issued. Customers can see when their return is checked in, when it’s inspected, and when a refund or exchange decision is made. This level of transparency reduces uncertainty and minimizes the need for customers to contact support for updates.

Automated refund processing ensures that once a return meets the policy requirements, refunds are issued quickly. Customers are notified immediately, with details on when they can expect the funds to appear in their accounts.

For returns that don’t meet the requirements, automation can still improve the experience. Instead of sending a generic rejection message, systems can provide specific explanations - sometimes even with photos showing the condition of the item. This clarity helps customers understand the decision and explore their next steps.

Integration with customer service tools ensures that, when customers do need to reach out, support teams have all the information they need. This prevents customers from having to repeat their stories and allows for faster resolution of more complex issues.

Smart 3PLs also use this communication touchpoint to enhance customer relationships. Automated messages might include personalized product recommendations, exclusive discount codes, or invitations to join loyalty programs. These thoughtful touches not only resolve the immediate issue but also leave customers with a positive impression that can drive future sales.

Choosing the Right 3PL for Reverse Logistics

Picking the right third-party logistics (3PL) partner for reverse logistics isn't just a box to check - it's a decision that can directly impact your bottom line and customer satisfaction. A misstep here could mean delayed refunds, unhappy customers, and higher costs. To make an informed choice, you need to evaluate potential partners using clear and relevant criteria.

Key Selection Criteria for 3PLs

When evaluating 3PLs for reverse logistics, focus on these critical factors:

- Geographic coverage: Your 3PL should operate in your key markets to ensure returns are handled quickly and cost-effectively. This alignment minimizes shipping delays and reduces expenses.

- Technology integration: Seamless communication between your eCommerce platform (like Shopify, WooCommerce, or Amazon) and your 3PL is a must. Without proper integration, you'll face manual data entry, slow updates, and inconsistent communication with customers. Look for providers that offer fast API integration to keep everything running smoothly.

- Reverse logistics expertise: Not all fulfillment experience translates to returns. Choose a provider with a track record in handling product inspections, refurbishments, and proper disposal. They should also have workflows tailored to different product categories and return scenarios.

- Cost transparency: Reverse logistics often involves layered fees for inspection, restocking, disposal, and storage. Insist on itemized pricing to avoid surprises later.

- Scalability and flexibility: As your business grows, so will your returns. You need a 3PL that can handle seasonal spikes and promotional surges without compromising service quality.

- Environmental compliance: For industries like electronics or cosmetics, regulatory compliance is non-negotiable. Ensure your 3PL works with certified recyclers and adheres to proper waste management practices.

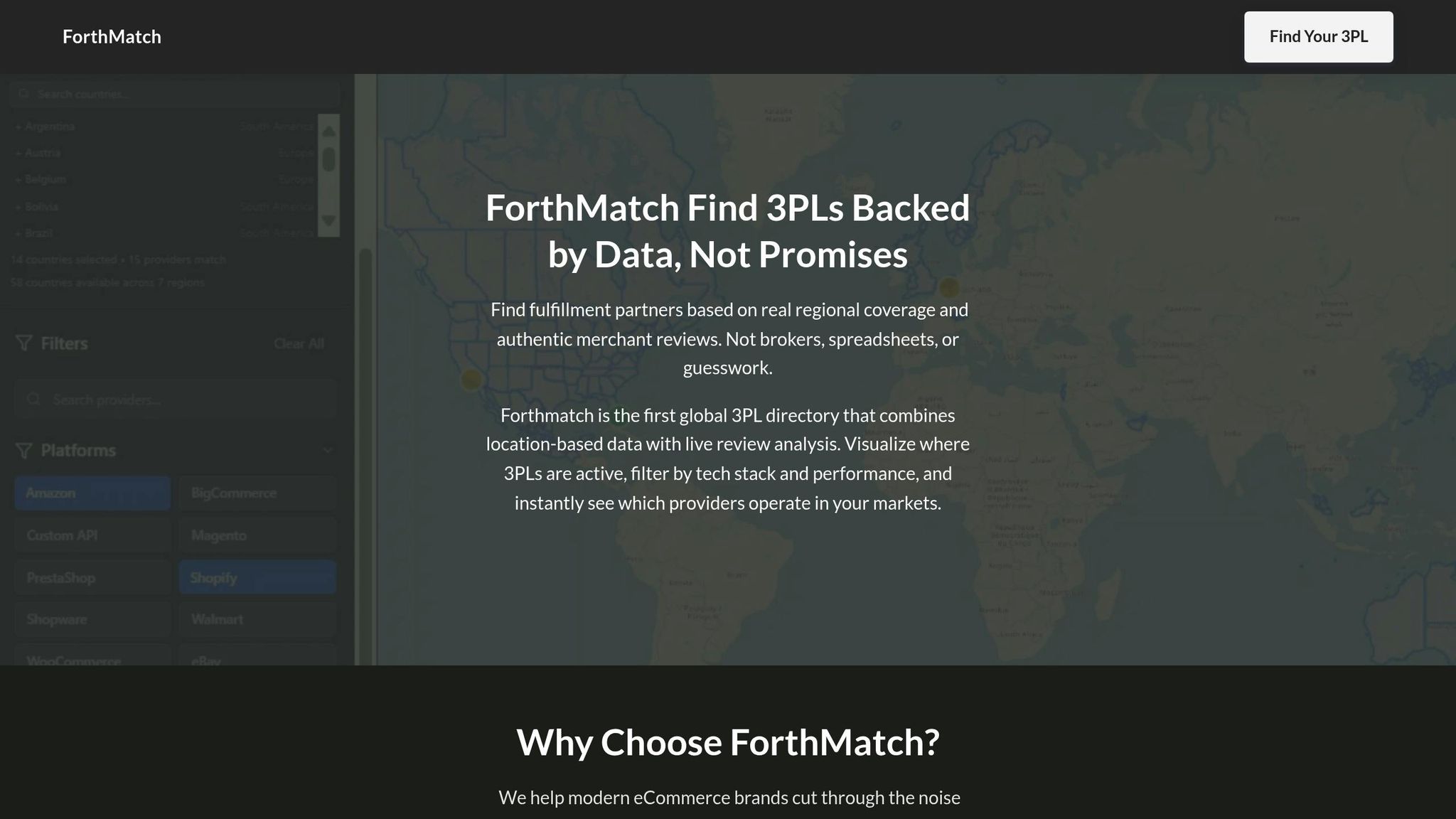

Using Forthmatch for 3PL Selection

Forthmatch simplifies the daunting task of finding the right 3PL partner. This platform is designed to connect DTC brands with vetted 3PL providers, eliminating the usual headaches of lengthy forms, brokers, and delays.

One standout feature is the real-time service area maps. These let you see exactly where each 3PL operates, so you can quickly determine if their coverage aligns with your return patterns. No more guessing - just clear, actionable insights.

Another game-changer is the platform compatibility filters. If your eCommerce setup relies on Shopify Plus or specific returns management apps, you can filter for 3PLs that integrate seamlessly with your existing tools. This feature saves time and ensures you avoid tech mismatches.

Forthmatch also enables direct contact with providers, cutting out brokers and their fees. Once you've identified a potential partner, you can reach out directly to negotiate terms and discuss your needs. This direct approach simplifies pricing discussions and ensures transparency.

For added confidence, the platform includes data-driven trust scoring. Instead of relying on marketing claims, you can evaluate providers based on their reputation, performance metrics, and credibility. This objective scoring system helps you identify 3PLs with a proven track record in reverse logistics.

Finally, the platform's search and filtering tools allow you to zero in on providers with specific expertise in reverse logistics. This targeted approach ensures you're not wasting time on general fulfillment providers who may lack the specialized knowledge your business needs.

Key Takeaways

Reverse logistics plays a crucial role in eCommerce. Choosing the right third-party logistics (3PL) provider can transform returns from a financial burden into a strategic advantage. Leading direct-to-consumer (DTC) brands understand that returns aren't just a cost of doing business - they're an opportunity to strengthen customer loyalty and reclaim value from returned inventory.

A strong tech setup, combining Return Management Systems (RMS) and Warehouse Management Systems (WMS), can simplify the entire process. These tools help automate inspections, track product conditions, and determine whether items should be restocked, refurbished, or disposed of. On top of that, data analytics can reveal return trends and help you tackle the root causes, reducing return rates over time.

Customer communication is a key piece of the puzzle during the returns process. Clear policies, automated updates, and fast refunds enhance customer satisfaction and encourage repeat purchases. A good 3PL should integrate smoothly with your eCommerce platform, offering real-time updates and consistent messaging. This level of transparency and efficiency lays the groundwork for choosing the right 3PL partner.

When evaluating a 3PL for reverse logistics, geographic reach, technology integration, and specialized expertise are critical considerations. Cost transparency and adherence to environmental standards are also essential, especially for brands managing regulated products or catering to eco-conscious customers.

Forthmatch simplifies the 3PL selection process with tools like real-time service area maps, compatibility filters, and direct access to providers. Its data-driven trust scoring removes uncertainty, while the platform’s broker-free approach ensures open and straightforward pricing discussions.

FAQs

How can a 3PL provider help streamline my reverse logistics process?

Partnering with a third-party logistics (3PL) provider can simplify and improve the way your business handles returns. Their expertise allows them to manage key aspects like consolidating shipments, optimizing transportation routes, and taking care of inspections, restocking, and repairs - all through integrated systems that keep things running smoothly.

Many 3PL providers also rely on advanced technology and data analytics to refine workflows, offer real-time tracking, and maintain clear communication with customers. By streamlining these processes, they can help cut costs, reduce delays, and enhance customer satisfaction, making returns and exchanges far easier for both your business and your customers.

How do Returns Management Systems (RMS) and Warehouse Management Systems (WMS) improve reverse logistics?

Returns Management Systems (RMS) are designed to centralize and automate the returns process, making it easier to manage tasks and data in one place. By simplifying the tracking, processing, and analysis of returns, these systems help reduce errors, improve efficiency, and uncover trends that businesses can use to refine their operations.

Warehouse Management Systems (WMS) work hand-in-hand with RMS to handle returned inventory more effectively. They monitor products as they arrive, streamline storage and routing, and ensure seamless coordination between inbound and outbound workflows. Together, RMS and WMS improve the speed, precision, and cost-efficiency of reverse logistics, enabling businesses to manage returns more effectively while delivering a smoother experience for customers.

What should I look for in a 3PL provider to handle product returns and meet environmental standards?

When selecting a 3PL provider to manage product returns, it's crucial to assess their capability in handling reverse logistics effectively while ensuring compliance with environmental regulations. Look for providers experienced in managing Extended Producer Responsibility (EPR) obligations and adhering to the U.S. Environmental Protection Agency (EPA) guidelines for reverse distribution processes.

It's also worth considering their dedication to sustainability efforts. This might include actions like reducing waste, running recycling programs, or improving transportation routes to cut down on emissions. Partnering with a provider that prioritizes environmentally conscious practices not only helps meet legal requirements but also supports your company’s broader sustainability objectives.