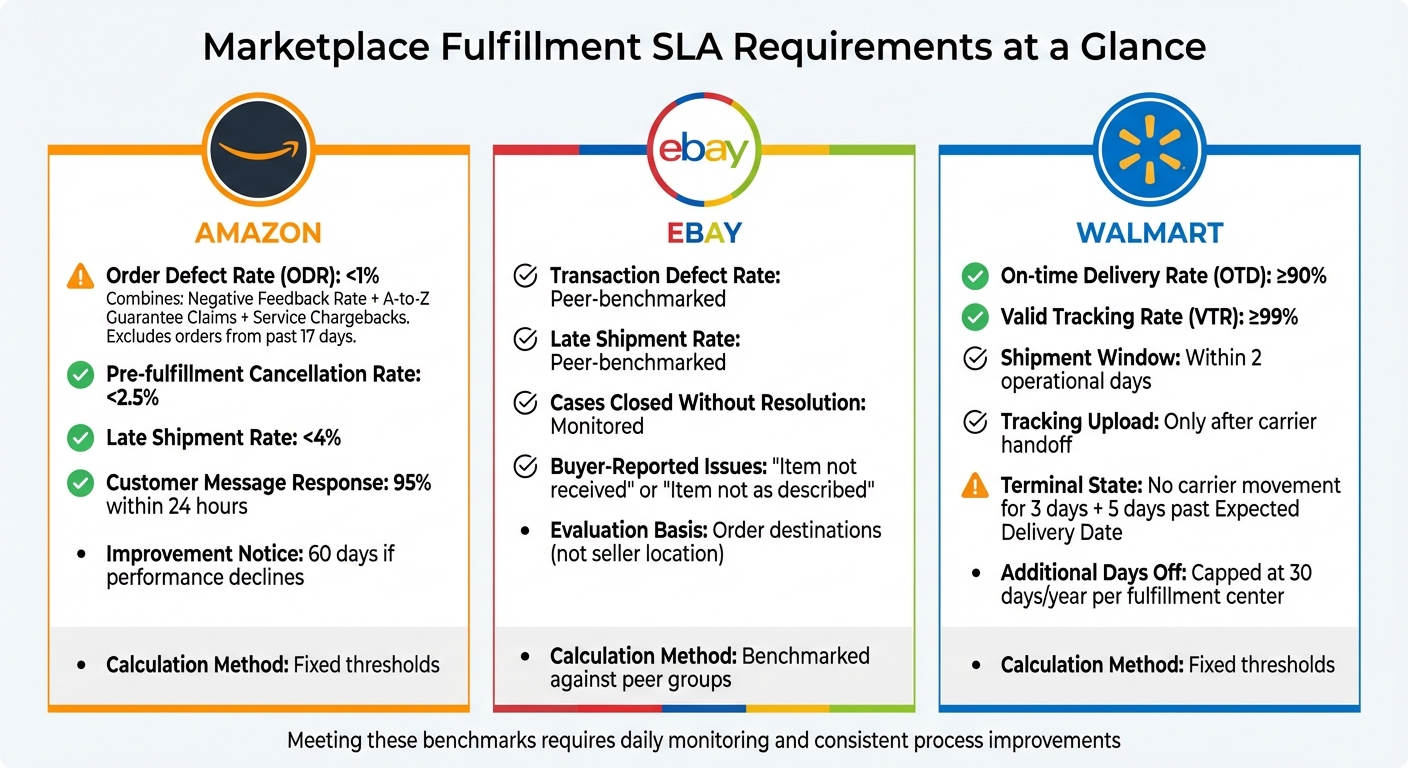

Marketplace fulfillment SLAs are strict performance metrics sellers must meet to maintain account health and avoid penalties. Key requirements include shipping on time, accurate tracking, and maintaining low defect rates. Falling short can lead to suppressed listings, withheld funds, or account suspension. Here's what you need to know:

- Amazon: Keep Order Defect Rate (ODR) below 1%, Late Shipment Rate under 4%, and respond to 95% of buyer messages within 24 hours.

- Walmart: Ensure 90% On-time Delivery Rate and 99% Valid Tracking Rate.

- eBay: Metrics like transaction defect rate and late shipment rate are benchmarked against peers.

Actionable Steps:

- Monitor performance dashboards daily.

- Set internal targets tighter than marketplace thresholds.

- Use centralized systems to track orders and ensure timely processing.

- Partner with reliable 3PLs and hold them accountable to SLA standards.

- Regularly analyze data to identify and fix recurring issues.

Meeting these benchmarks requires consistent tracking and process improvements. Staying compliant not only avoids penalties but also builds customer trust and long-term success.

How to: Multi Channel Fulfillment Order - Ship a non Amazon Order FBA MCF (eBay/Walmart)

Understanding Marketplace SLA Requirements

Marketplace Fulfillment SLA Requirements Comparison: Amazon, eBay, and Walmart

Each marketplace has its own set of fulfillment standards, and meeting these is crucial for maintaining seller performance. Take Amazon, for example: they require an Order Defect Rate (ODR) below 1%, a Pre-fulfillment Cancellation Rate under 2.5%, and a Late Shipment Rate below 4%. Amazon's ODR combines three factors: Negative Feedback Rate, A-to-Z Guarantee Claim Rate, and Service Chargeback Rate. Notably, orders placed within the past 17 days are excluded from ODR calculations, as this window allows time for potential customer complaints to surface.

eBay uses two systems - Seller Standards and Service Metrics - to evaluate sellers. These systems track metrics like transaction defect rate, late shipment rate, cases closed without seller resolution, and buyer-reported issues such as "Item not received" or "Item not as described." Unlike Amazon's fixed thresholds, eBay benchmarks sellers against peer groups, flagging those with higher rates of buyer-reported problems. eBay's evaluation is based on order destinations rather than the seller's location.

Walmart's requirements are equally stringent. Sellers must maintain a ≥90% On-time Delivery Rate, a ≥99% Valid Tracking Rate, and ensure shipments occur within two operational days. Walmart is particularly strict about tracking accuracy; tracking numbers should only be provided once the package has been physically handed over to the carrier. If a package shows no carrier movement for three days and is five days past the Expected Delivery Date, Walmart considers it in a "terminal state" and may cancel the order.

Core SLA Metrics by Platform

Every marketplace monitors specific metrics that shape how you manage your fulfillment operations. For example, Amazon's Late Shipment Rate focuses on whether shipments are confirmed by the expected ship date, which is tied to your handling time (defaulting to 1–2 business days if not otherwise set). This means you'll need to streamline both order processing and shipment confirmation.

| Marketplace | Key Metric | Required Threshold | Calculation Method |

|---|---|---|---|

| Amazon | Order Defect Rate (ODR) | <1% | Combines negative feedback, A-to-Z claims, and chargebacks |

| Pre-fulfillment Cancellation Rate | <2.5% | Orders canceled before shipment | |

| Late Shipment Rate | <4% | Shipments not confirmed by expected ship date | |

| eBay | Transaction Defect Rate | Peer-benchmarked | Evaluated against similar sellers |

| Late Shipment Rate | Peer-benchmarked | Compared to category averages | |

| Walmart | On-time Delivery Rate (OTD) | ≥90% | Actual delivery versus Expected Delivery Date |

| Valid Tracking Rate (VTR) | ≥99% | Accurate tracking numbers provided |

Amazon provides sellers with a 60-day improvement notice if performance declines. On the other hand, Walmart closely monitors the use of Additional Days Off, which are capped at 30 days per fulfillment center annually; excessive use may result in account suspension.

Converting SLA Policies into Daily Targets

To translate percentage thresholds into actionable daily goals, you need to calculate your maximum allowable failures. For instance, if you process 1,000 orders per month, a 4% Late Shipment Rate means you can have up to 40 late shipments - or roughly 1–2 per day.

Your handling time plays a significant role in meeting these targets. For example, with a two-business-day handling time, an order placed on Monday at 2:00 PM must be shipped by the end of Wednesday. Adjust your cutoff times to align with your actual processing capacity.

Carrier transit times also set tight deadlines. Consider this scenario: shipping from California to New York with a three-day ground service carrier, while Walmart requires delivery within five days of order placement. This leaves just two days for processing and handoff. You’ll need to work backward from the Expected Delivery Date, factoring in weekends, holidays, and carrier pickup schedules, to determine the latest possible ship date.

These calculations feed into a centralized tracking system, helping you maintain consistent performance across platforms.

Building a Multi-Platform SLA Tracking Matrix

Managing multiple marketplaces effectively requires a centralized tracking matrix. This tool should capture each platform's requirements, seasonal adjustments, and program-specific standards. Include columns for key metrics like ODR, Late Shipment Rate, and Valid Tracking Rate, and rows for each marketplace - plus extra rows for premium programs or seasonal variations. For example:

- Amazon's requirements remain steady year-round.

- eBay's peer benchmarking means acceptable performance thresholds may shift over time.

- Walmart doesn't publicly announce seasonal changes, but faster fulfillment is typically expected during Q4.

Regularly update your matrix using data from marketplace dashboards. Check Amazon Seller Central's Account Health page, eBay's Seller Standards dashboard, and Walmart Seller Center's performance reports daily. These platforms are the most reliable sources for tracking your account status.

Document any policy changes or new program requirements. For instance, Amazon Seller Fulfilled Prime demands a 99% on-time delivery rate and same-day or one-day delivery speeds - much stricter than standard requirements. Keeping these details in your tracking matrix ensures your team prioritizes orders that require expedited handling.

With your metrics clearly outlined, the next step is to fine-tune your internal processes to meet these targets.

Setting Internal Fulfillment Standards That Meet Marketplace SLAs

To consistently meet - and even exceed - marketplace SLAs, it's essential to establish strong internal fulfillment standards. These standards should align with the operational metrics that directly impact your performance on platforms like Amazon and Walmart. For example, Amazon requires sellers to maintain a Late Shipment Rate below 4%, while Walmart sets a 92% On-time Delivery threshold. Achieving these goals starts with tracking key internal metrics such as inventory accuracy, dock-to-stock times, and same-day shipping rates.

Inventory accuracy is a critical starting point. If your system shows stock that isn’t actually available, you risk cancellations that could hurt your Amazon Pre-fulfillment Cancellation Rate. Maintaining at least 98% inventory accuracy is non-negotiable. Similarly, completing dock-to-stock processes within two hours ensures inventory is ready for fulfillment without delays. For same-day shipping, aim to process and ship 95% of standard orders received by noon on the same day. These practices help avoid order cancellations and keep your SLA performance intact.

Another key metric is order drop-to-ship time, which measures the time between receiving an order and handing it off to the carrier. For expedited orders, aim to ship at least 97% of those received by 2:00 PM. Accuracy is equally important - every incorrect order costs $35–$50 to resolve, not to mention the potential loss of customer trust. Implement safeguards like secure packaging, automated checks, and staff training to ensure orders leave your facility error-free. While many companies report order accuracy rates between 95% and 100%, even a 1% error rate can result in 10 defective orders per 1,000 - dangerously close to Amazon's 1% Order Defect Rate threshold.

Internal Metrics That Drive SLA Compliance

To stay on track with marketplace SLAs, your warehouse operations need measurable benchmarks that directly influence performance. One such metric is the unit fill rate, which measures your ability to ship complete orders without splitting or back-ordering items. Strive for a 100% initial order fill rate, as incomplete shipments frustrate customers and contribute to negative feedback, which can increase your Order Defect Rate. Industry averages for unit fill rates range from 60% to 92%, but top performers consistently hit the 100% mark.

Returns processing speed is another critical factor. Efficient returns management not only improves customer satisfaction but also ensures faster restocking. Aim to process returns within 8–12 hours of receipt, with a target of completing 97% of returns within two business days. Faster processing reduces complaints about delayed refunds and keeps inventory available for resale.

Additionally, track carrier handoff times separately from order processing. For instance, if a carrier pickup is scheduled for 3:00 PM but your packing process runs late, the order risks missing the same-day shipment window. Walmart’s Valid Tracking Rate requirement of 99% or higher means you must upload tracking numbers only after packages leave your facility.

Writing 3PL Contracts That Guarantee SLA Performance

When outsourcing fulfillment to a 3PL, your contract should include detailed SLA clauses that align with marketplace requirements. Define what constitutes "on-time shipment" - for instance, orders received by 12:00 PM EST must ship the same day, with tracking uploaded within two hours of carrier pickup. Require inventory accuracy standards of 98% or higher, verified through regular cycle counts.

Include performance benchmarks that meet or exceed marketplace thresholds. For example, set a Late Shipment Rate at least 1% lower than the marketplace standard to create a safety buffer. For Walmart sellers, require a 92% or higher On-time Delivery Rate. Additionally, document how your 3PL will handle peak seasons, federal holidays, and unexpected carrier delays without compromising SLA performance.

Accountability is key. Require weekly performance reports detailing metrics like order accuracy, same-day shipping rates, and dock-to-stock times. When vetting potential 3PL partners, ask for historical performance data that demonstrates their ability to meet marketplace standards. For example, a 3PL claiming to meet Amazon Seller Fulfilled Prime’s 99% on-time delivery rate should provide evidence to back up their claims. Platforms like Forthmatch can offer real-time analytics and insights to help you evaluate 3PL performance.

Adapting SLAs for U.S. Fulfillment Operations

U.S. fulfillment operations require adjustments based on geography, carrier schedules, and federal holidays. For instance, configure your order management system to automatically account for federal holidays like Thanksgiving, Christmas, and Independence Day by extending handling times. This ensures you remain compliant with marketplace SLAs during non-operational days.

Time zone differences also play a significant role. Walmart requires sellers to set operating schedules and cutoff times based on the local time zone of each fulfillment center. For example, an order received at 11:00 AM PST in Los Angeles is effectively 2:00 PM EST in Atlanta, potentially missing the same-day cutoff for your East Coast facility. To avoid such issues, set warehouse-specific cutoff times and route orders to the nearest facility to minimize transit times.

Carrier transit times vary widely across the U.S. Ground shipping from California to New York might take 5–6 business days, while shipping from California to Nevada could take just 1–2 days. To optimize delivery times, consider a bi-coastal inventory strategy, placing stock in both West Coast and East Coast warehouses. This setup can ensure ground transit times of three days or less for 95% of U.S. addresses, reducing the need for costly expedited shipping.

Peak seasons, such as Black Friday through Christmas, Prime Day, and back-to-school, bring additional challenges. Carriers often revise shipping cutoff times and may suspend overnight service guarantees during these periods. Proactively communicate with your 3PL about forecasted volumes, promotional schedules, and inbound shipments to ensure they allocate sufficient resources to handle the increased demand. This preparation can help you maintain SLA compliance even during the busiest times of the year.

sbb-itb-eb0f906

Creating Workflows That Deliver Consistent SLA Performance

To meet marketplace SLAs effectively, you need workflows designed for precision and efficiency. Think of your operations as a well-oiled machine, where every process is fine-tuned to ensure orders move smoothly from acceptance to carrier handoff. A good starting point? A centralized order management system. By consolidating orders from multiple marketplaces into a single platform, you reduce the risk of errors and ensure rapid processing - especially critical when platforms demand order acceptance within 24 hours. These proactive measures align your internal fulfillment processes with marketplace expectations, ensuring every order meets SLA requirements.

Standard Order Processing Workflows

The backbone of consistent SLA performance is a unified order management system. Platforms like Amazon, Walmart, and eBay can all feed into one dashboard, making it easier to track, manage, and process orders. This approach not only minimizes the chances of missed orders but also automates key tasks like order acceptance and tracking. To stay ahead, set internal targets that align with the specific requirements of each marketplace. Automated stock alerts and reorder points can further safeguard against stockouts, keeping your fulfillment process running smoothly.

Using FIFO (First-In, First-Out) inventory rotation can also make a big difference. It helps maintain product freshness and speeds up backorder fulfillment by cutting down on unnecessary delays. For added efficiency, document procedures for handling exceptions - like address errors, payment holds, or partial shipments - and establish clear receiving protocols to address delivery discrepancies on the spot.

Preventing SLA Failures Before They Happen

Beyond efficient order processing, smart inventory management plays a key role in avoiding SLA breaches. If a large share of your orders is concentrated in a specific region, consider positioning inventory locally to meet delivery deadlines with ground shipping. Your carrier choices should also align with your delivery promises. For example, if you offer two-day delivery, work with regional carriers or maintain inventory in multiple strategic locations to meet that commitment. For fast-moving items, keep a safety stock buffer of 10–15 days to avoid stockouts.

Packing standards and cross-check procedures are equally important. Clear guidelines and quality checks can help minimize shipping errors and defects, reducing the risk of SLA failures.

Monitoring and Managing 3PL Performance

If you’re working with a third-party logistics (3PL) provider, keeping a close eye on their performance is essential. Regular reviews of key metrics - like same-day shipping rates, order accuracy, and dock-to-stock times - can reveal how well they’re meeting your expectations. Compare their performance against your agreed SLAs. If discrepancies arise, such as falling inventory accuracy or shipping delays, investigate the root cause immediately. Whether it’s a staffing issue, carrier delays, or system errors, require your 3PL to implement corrective actions with clear deadlines.

Accountability is key to maintaining SLA compliance. Structured review sessions can help drive improvements. For example, Forthmatch offers 3PL accountability sessions for $50, allowing you to set performance benchmarks and track progress over time. Request detailed reports segmented by warehouse location or product category to identify trends and areas for optimization. These insights ensure your 3PL stays aligned with your operational standards, keeping your SLA performance on track.

Tracking and Improving SLA Performance Over Time

Meeting marketplace SLAs isn't something you achieve once and forget about - it demands ongoing attention and fine-tuning. Real-time SLA monitoring is key to ensuring your fulfillment services consistently meet the performance metrics and targets you've committed to. This not only keeps you accountable but also helps you make steady progress over time.

Setting Up Real-Time SLA Monitoring

A solid real-time monitoring system gives you live data, customizable alerts, and uninterrupted functionality. Start by regularly reviewing marketplace dashboards and seller scorecards. Platforms like Amazon's Seller Central, Walmart's Seller Center, and eBay's Seller Hub provide performance metrics updated throughout the day. Set up early warning alerts for critical metrics like on-time delivery rate and valid tracking rate. For example, if your goal is a 95% on-time delivery rate, configure alerts to notify you if performance dips below 93%. This allows you to address potential problems before they escalate into compliance issues.

SLA management software can streamline this process by defining SLA rules, tracking performance data in real time, and comparing results against your targets. With tools like Forthmatch's real-time performance dashboard, you can automate SLA and KPI tracking across your fulfillment operations, ensuring nothing gets overlooked.

Use these real-time alerts as a starting point for a deeper dive into your performance metrics.

Analyzing Performance Data to Find Patterns

To improve, you need to understand the story your data is telling. For customer communication SLAs, monitor metrics like response time ratio, average response time, message volume trends, resolved versus pending cases, and complaint rates. For fulfillment operations, focus on key metrics such as initial order fill rate, percentage of same-day shipments, error-free shipping rates, dock-to-stock time, and returns processing time. Breaking down this data by SKU, region, carrier, or warehouse can help you uncover recurring issues. For instance, if a specific carrier is consistently late in a certain ZIP code, you can adjust your shipping strategy to address the problem.

Forthmatch's SLA Analytics Hub ($9/month) offers detailed reporting, export options, and issue categorization. By segmenting your performance data, you can identify challenges tied to specific products, regions, or fulfillment partners - turning raw data into actionable insights.

These insights are the foundation for targeted improvements.

Running Improvement Cycles and Measuring Results

Once you've analyzed your data, it's time to act. Begin by measuring your current performance to establish a baseline. An effective improvement cycle combines real-time monitoring, data-driven analysis, and iterative process tweaks. For instance, if you introduce a new packing method, compare order accuracy rates before and after the change to evaluate its effectiveness.

Historical benchmarking and analytics tools can help you track progress over time. Forthmatch's structured 3PL accountability sessions ($50 per session) are designed to help you establish baseline metrics and monitor improvements. These sessions provide clear evidence of whether your changes are working. Keep a record of each improvement cycle, including dates, actions taken, and measurable results, to identify what works best and refine your processes further.

Conclusion

Meeting marketplace fulfillment SLA requirements isn’t a one-and-done task - it’s an ongoing process that requires your internal operations to stay in sync with platform standards. For instance, knowing metrics like Amazon’s target response time of 95% or Walmart’s on-time delivery rate of 90% or higher is just the starting point. Turning these benchmarks into actionable daily goals ensures your team maintains steady and reliable performance.

Staying on top of these metrics is what separates successful sellers from those who face penalties. Real-time tracking of KPIs allows you to spot and fix issues before they snowball into account suspensions or listing suppressions . Using performance management tools that centralize data from multiple marketplaces gives you the clarity to act quickly and effectively when challenges arise. This level of visibility also lays the groundwork for building strong partnerships that help you consistently meet SLA requirements.

Partnering with 3PL providers is a key piece of the puzzle. By negotiating contracts that guarantee SLA adherence and conducting regular reviews focusing on metrics like order accuracy and on-time shipping, you create a system of accountability that delivers results. When combined with tech-driven workflows, these partnerships provide the flexibility and transparency needed to maintain high service levels. Tools like Forthmatch (https://forthmatch.io) can further simplify the process of finding reliable 3PL providers tailored to direct-to-consumer brands.

Ultimately, the top-performing sellers treat SLA compliance as part of a continuous improvement cycle. By analyzing performance data, running improvement tests, and measuring their impact, you develop a fulfillment operation that not only meets but exceeds marketplace expectations. This proactive, data-driven approach ensures you’re not just keeping up with standards but setting the stage for long-term growth and customer satisfaction across all your marketplace platforms.

FAQs

What are the key differences in fulfillment SLA requirements for Amazon, eBay, and Walmart?

The shipping and fulfillment requirements for Amazon, eBay, and Walmart reflect each platform's distinct priorities:

- Amazon: Sellers are typically required to ship orders within 1 to 5 days, with same-day or next-day delivery often being the norm. Amazon also expects extremely high order accuracy, with a target of around 99.9%.

- eBay: Unlike Amazon and Walmart, eBay’s shipping timeframes and accuracy expectations are not as clearly outlined in publicly available information. This makes their requirements less rigid and provides sellers with more flexibility.

- Walmart: Sellers must ship orders within 2 business days unless they have an approved lag-time exemption. Additionally, sellers are required to log lag-time details at the SKU level, which directly affects their eligibility for Walmart’s One-Day and Two-Day delivery programs.

Among the three, Amazon sets the bar high for speed and precision, Walmart enforces tighter shipping windows, and eBay offers more leeway in its fulfillment requirements.

How can sellers track and improve their marketplace SLA performance?

To keep SLA performance on track and improve it over time, sellers need to focus on consistent monitoring and timely adjustments. Begin by keeping an eye on key metrics, such as on-time delivery rates and valid tracking compliance, using your marketplace dashboard. Set specific goals - like maintaining at least a 96% on-time delivery rate - and use alerts to quickly address potential problems.

Take time to regularly audit tracking numbers and assess how well your carriers are performing. If delays become a recurring issue, it might be worth exploring more dependable carriers or fine-tuning internal processes like order picking and packaging. Look for patterns in problem rates to pinpoint the root causes and address them with targeted solutions.

For businesses aiming to scale, partnering with a trusted third-party logistics (3PL) provider can be a game-changer. Tools like Forthmatch let you compare 3PL options based on delivery reliability and other key factors, ensuring you meet SLA standards without unexpected costs. By combining routine reviews, process optimizations, and dependable partnerships, sellers can steadily boost their SLA performance.

What key elements should a 3PL contract include to meet SLA requirements?

To keep everything running smoothly and meet SLA requirements, a 3PL contract needs to spell out the services offered and set clear, measurable performance benchmarks. These might include things like delivery timelines, order accuracy rates, and how quickly returns are processed. It should also detail reporting procedures, include penalties or credits for not meeting targets, and lay out steps for escalation and resolving disputes.

The contract should also cover handling and safety protocols, terms for inventory management, and procedures for receiving and counting stock. These specifics help ensure your logistics partner stays accountable and consistently meets your marketplace fulfillment expectations.