Choosing between in-house and outsourced fulfillment boils down to control versus flexibility. If you want full oversight of your operations, in-house fulfillment might be the way to go. But if you’re looking for scalability and lower upfront costs, outsourcing to a 3PL provider could be the smarter choice. Both models have unique cost structures and trade-offs, so understanding the breakdown is key.

Key Takeaways:

- In-house fulfillment: High upfront costs (e.g., $50,000–$200,000) for warehousing, labor, and technology. Best for businesses prioritizing control and brand consistency.

- Outsourced fulfillment (3PL): Lower initial investment ($1,000–$5,000) with variable costs that adjust to demand. Ideal for growing or seasonal businesses.

Quick Comparison:

| Factor | In-House Fulfillment | 3PL Fulfillment |

|---|---|---|

| Costs | Fixed, high upfront investment | Variable, pay-as-you-go |

| Control | Full oversight | Limited, managed by provider |

| Scalability | Limited by physical infrastructure | Adjusts to demand |

| Setup Time | Longer | Faster |

| Best For | Established brands with steady demand | Growing or seasonal businesses |

Both approaches have their pros and cons. Your choice should align with your business size, growth plans, and priorities.

3PL vs. In-House Fulfillment: Which is Right for Your Brand?

1. In-House Fulfillment Costs

Handling your fulfillment operations in-house comes with a variety of hidden expenses that can significantly inflate your overall costs. If you only consider labor expenses, you might underestimate your total fulfillment cost per order by up to 50%. Let’s break down the major cost categories involved.

The first piece of the puzzle is warehousing. Renting or purchasing space brings costs like utilities, maintenance, and repairs. Be aware that warehouse rental rates can climb by as much as 10%. These expenses form the foundation of your fulfillment operation.

Next, labor costs are often the largest chunk of your budget. These include salaries, benefits, overtime, recruitment, training, and management oversight. Leadership time spent on fulfillment-related tasks also adds to the expense.

Your technology infrastructure is another key factor. A warehouse management system (WMS) is essential for tracking inventory and orders, but it doesn’t come cheap. You’ll also need equipment like barcode scanners, automation tools, and regular system updates and maintenance to keep everything running smoothly.

Inventory management introduces both direct and indirect costs. Storage fees are typically based on volume or pallet size. Then, there’s inventory depreciation and stock insurance to consider. Mismanaged inventory can be a costly mistake: retailers lose $349 billion annually due to stockouts. On the flip side, overstocking ties up valuable capital and increases storage costs.

Variable costs, such as packaging, shipping, and utilities, grow with your order volume. For instance, pick-and-pack fees range from $0.20 to $5 per item. Shipping alone accounts for an average of 8.7% of merchants’ yearly expenses. These costs can be particularly tricky to manage during periods of rapid growth.

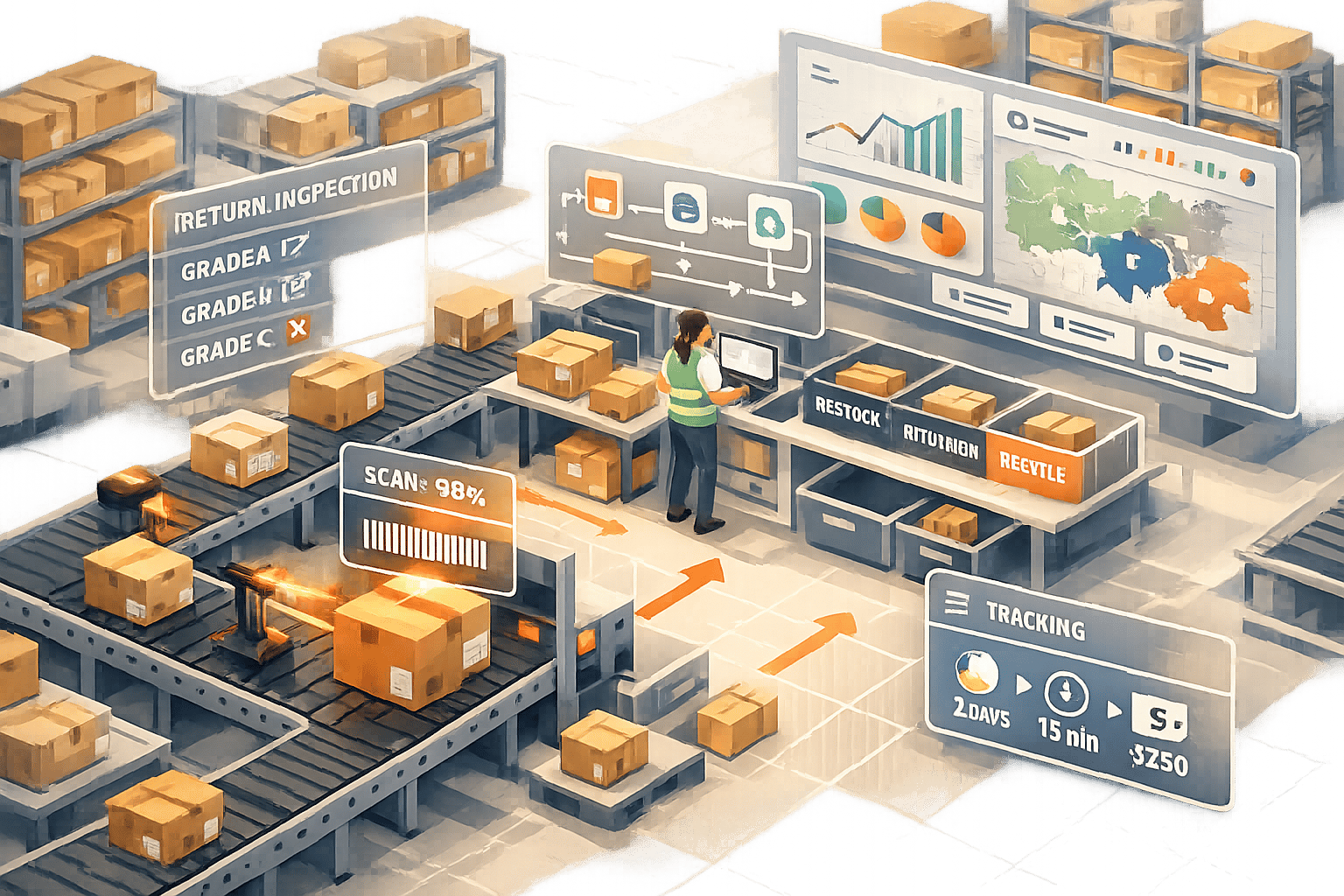

Don’t overlook administrative expenses. You’ll need staff for customer service and order management, as well as office supplies, equipment, and compliance-related fees. Returns management also adds hidden costs, including labor for processing, restocking fees, and losses from damaged returned items [17, 19].

Here’s a quick summary of the main cost categories and their components:

| Cost Category | Key Components |

|---|---|

| Warehousing Costs | Rent/lease payments, utilities, facility and equipment maintenance/repairs |

| Labor Costs | Salaries, benefits, overtime, training, and certification |

| Technology Costs | WMS software, automation tools, system maintenance and updates |

| Inventory Costs | Storage fees, inventory depreciation, stock insurance |

| Fulfillment Fees | Picking and packing labor, packaging materials, equipment like scanners |

| Administrative Costs | Customer service staff, office supplies, compliance fees |

Scaling your operations adds another layer of complexity. As order volumes increase, you’ll need to expand staffing, warehouse space, and equipment. These infrastructure investments often require significant upfront costs, even before your revenue catches up to justify them.

To get a clear picture of your in-house fulfillment costs, use this formula:

Total Fulfillment Cost = Total Warehousing Costs + Total Picking & Packing Costs + Total Shipping Costs + Total Labor Costs.

Make sure to account for all indirect expenses to fully understand your true fulfillment costs. This comprehensive understanding is essential when comparing in-house fulfillment to third-party logistics (3PL) options.

2. 3PL Fulfillment Costs

One of the biggest advantages of using a third-party logistics (3PL) provider is the shift from fixed to variable costs. Unlike managing your own warehouse, where you're tied to fixed overhead costs, 3PL pricing adjusts based on your actual usage. This flexibility is especially helpful for businesses dealing with fluctuating demand. That said, understanding the full fee structure is essential for accurate cost planning. Let’s dive into the key setup and ongoing costs associated with 3PL services.

Setup and Onboarding Fees

Getting started with a 3PL provider involves some upfront costs. Onboarding fees for small eCommerce businesses typically average around $550, though they can range anywhere from $0 to $3,000 depending on the complexity of the setup. Setup fees, which cover things like account creation, system integration, and initial inventory processing, usually fall between $100 and $1,000. Additionally, technology and integration costs can add a one-time expense of $600 to $3,500.

Storage Costs

Storage is often one of the largest components of 3PL expenses, making up about 50% of total costs on average. Pricing models vary by provider:

- Pallet storage: Typically $5 to $15 per pallet monthly, though some providers charge as much as $15 to $40.

- Cubic foot pricing: Ranges from $0.30 to $0.55 per month for smaller items.

- Bin storage: Costs range from $1 to $2.50 per bin, with some providers charging $3 to $6.

"With your own warehouse, you pay for the entire space regardless of how much you use. If it's too big, you waste money. If it's too small, you face the cost of securing additional space. A 3PL lets you pay only for what you use and scale as needed."

- Tony Runyan, Chief Client Officer, Red Stag Fulfillment

Inbound Receiving and Fulfillment Fees

Inbound receiving, which involves getting your inventory into the 3PL’s warehouse system, typically costs:

- $20 to $50 per hour

- $5 to $15 per pallet

- Around $0.25 per item

Some providers may also charge $10 to $50 per pallet or $35 to $50 per hour, depending on their pricing structure.

Pick and pack fees, covering the cost of selecting and packaging orders, can range from $0.20 per item to as much as $5.00 per order for more complex setups. Fulfillment fees as a whole generally account for 25% to 35% of each order’s total cost.

Shipping Costs

Shipping costs include carrier charges along with any 3PL markups or discounts. Many 3PL providers offer shipping discounts of 10% to 30% off standard carrier rates, though some may add markups of 0% to 12%. Here’s a breakdown of typical shipping expenses:

- Base rates for small parcels: $8 to $18

- Residential delivery fees: $4.00 to $5.35 per package

- Fuel surcharges: 10% to 15% extra

- Rural delivery surcharges: $3.20 to $6.50

- Extended area surcharges (e.g., Alaska or Hawaii): $35 to $40

Returns Processing and Account Management

Returns processing is another cost to factor in, especially since 17.6% of online shoppers return products. Providers typically charge $1 to $3.50 for inspection and restocking, or $1 to $6 per return in some cases.

Account management fees vary widely, ranging from $75 to $250 per month as a flat rate, or $40 to $60 per hour. Some providers charge between $50 and $300 per month for this service. Additional services, like label printing or order inserts, may add $0.10 or more per shipment.

Pricing Models and Additional Fees

3PL providers use various pricing models that can significantly impact your overall costs. Common options include:

- Per-unit pricing: A fixed fee for each unit stored or shipped.

- Flat-rate pricing: Predictable monthly fees regardless of volume.

- Variable pricing: Costs adjust based on order volume and SKU count.

- Hybrid models: A mix of different pricing approaches.

"You need to understand the full pricing structure - storage, pick-and-pack fees, shipping rates, and any potential surcharges. A clear view of your total costs can help avoid surprises and make sure the 3PL aligns with your budget."

- Joe Spisak, CEO and Founder, Fulfill.com

Additional fees can also add up. For example, long-term storage fees may apply to slow-moving inventory, and special handling fees for fragile, oversized, or temperature-controlled items can range from $50 to $200 or more per month. Even small changes in package dimensions can increase storage and shipping costs.

sbb-itb-eb0f906

Pros and Cons Analysis

Building on the earlier cost breakdowns, this section dives into the trade-offs between in-house and outsourced fulfillment. Deciding between these models isn’t just about comparing upfront costs - it’s about figuring out which one aligns best with your business goals, growth plans, and operational needs. These choices influence not just your expenses but also your ability to scale and adapt.

In-House Fulfillment: Control Comes at a Price

With in-house fulfillment, you get full control over everything - from storing your products to packing and shipping orders. This level of oversight is especially valuable if your brand relies on a consistent customer experience or deals with specialized products. Plus, once you’ve made the initial investments in warehouse space, equipment, and staff, your ongoing costs tend to stabilize, which can simplify budgeting if your order volumes stay steady.

That said, there are some big challenges. Setting up in-house operations requires hefty upfront spending on real estate, technology, and staffing. You’ll also face ongoing costs like maintenance and utilities. Scaling can be tricky too - if demand dips, you’re still stuck paying for the same space and resources. And perhaps most importantly, running fulfillment can pull focus away from your core business. Tyler Sellers, Director of Operations at Red Stag Fulfillment, explains:

"Most ecommerce business owners are good at creating, marketing, and selling products. It's rare for an entrepreneur to be able to run a fulfillment operation successfully and scale it correctly without putting sales at risk."

3PL Fulfillment: Flexibility with Some Compromises

The appeal of third-party logistics (3PL) lies in its flexibility. Instead of committing to fixed warehouse costs, you pay based on what you use. This makes 3PL a great option for businesses with seasonal demand or those going through rapid growth.

Another advantage is expertise. Instead of building logistics capabilities from scratch, you can tap into the skills and systems of established providers. In fact, 81% of businesses using 3PL services report significant improvements in meeting customer needs. Financially, outsourcing can free up resources for other priorities. Tony Runyan highlights this benefit:

"Operational costs can be a profit-killer for growing businesses. Balancing cash flow and infrastructure investment with surging sales demand is no easy task. When you outsource logistics to a reliable third party, you'll have more capital available to invest into sales, marketing, and product development."

The numbers back this up. For example, Natural Dog Company saved $750,000 annually on postage and another $500,000 on rent and payroll after switching to a 3PL. Similarly, The Singing Machine Company estimated it would save $2.8 million annually by outsourcing its logistics.

However, outsourcing does mean giving up some control. Customization options can be limited, and any issues on the provider’s end - like delays or errors - can directly impact your business.

Side-by-Side Comparison

Here’s a quick look at how the two models stack up:

| Factor | In-House Fulfillment | 3PL Fulfillment |

|---|---|---|

| Best for | Companies needing maximum control | Businesses focused on growth and scaling |

| Cost structure | Fixed costs with high upfront investment | Variable costs with lower upfront investment |

| Control | Full oversight of all processes | Limited; operations handled by the provider |

| Expertise | Requires building in-house knowledge | Access to specialists without hiring |

| Scalability | Limited by physical infrastructure | Adjusts to demand fluctuations |

| Implementation | Longer setup with infrastructure needs | Faster setup time |

| Ideal when | Brand experience and consistency matter | Capital is tight and demand is variable |

When Each Model Makes Sense

In-house fulfillment is ideal for larger businesses with steady order volumes, those needing specialized handling, or companies prioritizing brand control over efficiency. If you’ve got the capital and want to oversee every customer interaction, this option could be the right fit.

On the other hand, 3PL services shine for businesses experiencing seasonal demand or rapid growth. With the global 3PL market projected at $1.29 trillion in 2024, it’s clear that many companies see the value in outsourcing logistics to scale efficiently while keeping fixed costs low.

Ultimately, the right choice depends on your priorities. If rapid growth and operational flexibility are key, 3PL might be your best bet. If control and customization are more important, in-house fulfillment could be the way to go. Some businesses even mix and match, handling core products internally while outsourcing less critical operations to third-party providers. By weighing these trade-offs against your overall goals and budget, you can find the model that fits your strategy.

Conclusion

Choosing the right fulfillment strategy boils down to your business's size, growth plans, and priorities.

For smaller direct-to-consumer (DTC) brands, outsourcing to a 3PL can lead to significant cost savings - typically cutting 30–40% off per-order expenses. Initial investments for 3PL services generally range from $1,000 to $5,000, compared to the hefty $50,000–$200,000 needed to establish an in-house operation. On the other hand, businesses experiencing rapid growth often benefit from the flexibility of 3PLs, which can handle seasonal spikes and scaling demands. However, fulfillment costs in such cases might average around 70% of an order's value.

For established brands managing high order volumes and requiring specialized handling, in-house fulfillment may become more economical in the long run. That said, this route demands substantial capital and operational expertise to execute effectively. These factors highlight the importance of aligning your fulfillment choice with your business's operational scale and goals.

The 3PL market is on track to hit $1.3 trillion by 2026, with over 24,000 providers in the U.S. alone. This gives businesses a wide array of outsourcing options. Evaluating potential partners should focus on aspects like technology integration, scalability, and transparent pricing to ensure a good fit.

Platforms like Forthmatch simplify this process by offering a vetted directory of 3PL providers. Their tools include transparent pricing and real-time service area maps, giving businesses direct access to providers without broker fees or hidden costs. This makes it easier to find fulfillment partners that align with your operational needs and future growth plans.

Ultimately, the best fulfillment model is one that serves your current needs while leaving room for future flexibility.

FAQs

What hidden costs should businesses consider when managing in-house fulfillment?

Many businesses tend to overlook the hidden expenses tied to managing fulfillment in-house. These can range from the costs of maintaining warehouse facilities and investing in necessary infrastructure to dealing with reverse logistics. On top of that, operational hiccups - like mistakes or shipping delays - can ramp up labor expenses and leave customers feeling frustrated.

There are also other often-missed costs, such as resource bottlenecks during busy seasons or the financial strain of holding onto dead stock. This unsold inventory not only eats up valuable storage space but also locks away capital that could be better used elsewhere. Taking a closer look at these factors can help you decide if handling fulfillment internally is actually the right move for your business.

How can a business decide if switching from in-house fulfillment to a 3PL provider is more cost-effective?

To figure out if partnering with a 3PL provider is more budget-friendly, start by comparing the fixed costs of managing your own fulfillment - like warehousing, labor, and technology - with the variable expenses tied to 3PL services. These might include storage, shipping, and handling fees. Don’t forget to factor in things like your order volume, how scalable your operations need to be, and the potential savings from discounted shipping rates that many 3PL providers can offer.

It’s also important to think about where your business stands in terms of growth and what your operational goals are. For example, if your current system is struggling to keep up with increasing demand or seasonal surges, outsourcing to a 3PL could offer the flexibility and cost savings you need. By carefully weighing these factors, you’ll be able to make a decision that aligns with your business needs and goals.

What should companies consider when selecting a 3PL provider to support their growth and operations?

When picking a 3PL provider, it's essential to assess their ability to scale alongside your business and the variety of services they offer to address both current demands and future growth. A good provider should bring solid industry knowledge, advanced technology systems for managing inventory and orders, and well-established carrier relationships to help streamline shipping times and costs.

You’ll also want to factor in their reliability, geographic coverage to support your target markets, and how well their services align with your operational goals. By making a decision based on data and careful evaluation, you can secure a partnership that not only meets your immediate needs but also supports your long-term growth strategy.