Managing returns is expensive, but reverse logistics software can help reduce costs significantly. By automating workflows, improving shipping efficiency, and reclaiming value from returned items, businesses can transform returns from a financial burden into a streamlined process. Here’s how:

- Automation: Speeds up returns by automating tasks like sorting, inventory updates, and refund processing, cutting labor costs and errors.

- Shipping Optimization: Selects cost-effective carriers and routes, consolidates shipments, and negotiates better rates to lower transportation expenses.

- Value Recovery: Quickly reintegrates sellable items into inventory or routes products for repair, reducing losses.

- Fraud Prevention: Tracks patterns to detect suspicious returns, saving billions lost annually to fraud.

- Metrics and Insights: Provides real-time data to improve processes, reduce return rates, and make informed decisions.

In 2024, U.S. retailers lost over $103 billion to inefficient returns and fraud, highlighting the need for smarter solutions. Reverse logistics software not only addresses these challenges but also boosts customer satisfaction by ensuring faster, smoother returns. Pairing this software with reliable 3PL providers further enhances efficiency and cost savings.

Takeaway: Automating returns, optimizing shipping, and reclaiming product value are key to reducing costs and improving operations.

Main Cost Drivers in Returns Management

Primary Returns Cost Components

Returns management involves several key expenses that can significantly affect profitability. One of the biggest costs is transportation, which includes the shipping of returned items from customers back to warehouses or processing centers. This is particularly costly in the U.S., where the vast geographic area and regional variations in shipping rates add complexity and expense.

Another major expense is labor costs, which cover tasks like inspecting returned items, issuing refunds, updating inventory records, and handling customer inquiries. The need for manual labor and extensive customer service efforts, especially during peak return periods, drives up these costs.

Inventory holding costs also play a significant role. These costs arise when returned items sit in warehouses waiting for processing or decisions about their next steps. This not only ties up valuable warehouse space and resources but also leads to potential losses in product value, especially for seasonal or fast-moving goods. The longer these items remain unprocessed, the greater the financial strain on the business.

Lastly, product disposition costs include the expenses associated with deciding the fate of returned goods. This could involve restocking, refurbishing, recycling, or disposing of items altogether. Each option requires different resources and comes with varying levels of value recovery. When manual processes dominate, these inefficiencies can further inflate costs.

Problems with Manual Returns Management

Manual processes in returns management often lead to inefficiencies that drive up operational costs. For instance, when staff manually inspect, sort, and restock returned products, the process becomes slow and error-prone. These delays reduce the resale value of items as they sit idle, missing the chance to be resold at their original price.

Errors in manual data entry only add to the problem, causing issues like incorrect inventory counts, inaccurate refund amounts, and discrepancies that require extra time and resources to fix. During busy return periods, manual systems struggle to scale, leading to backlogs that force companies to pay overtime or hire temporary staff.

Another issue is the lack of real-time visibility in manual systems. Without this, businesses can't easily track the status of returns, identify bottlenecks, or make informed decisions to improve processes. This lack of transparency also makes it harder to detect and prevent return fraud, which has become a growing expense for U.S. retailers.

Customer satisfaction also takes a hit with manual systems. Longer refund processing times and limited visibility into return statuses lead to more customer service inquiries. This not only increases staffing costs but also risks losing customers entirely - a costly outcome considering the high expense of acquiring new customers in today's competitive market.

U.S.-Specific Factors Affecting Returns Costs

In addition to the general cost drivers, certain factors unique to the U.S. market amplify these challenges. For one, U.S. consumers have come to expect free and fast returns. While this improves customer satisfaction, it also forces retailers to absorb higher shipping and processing costs.

The country’s vast size and varying shipping rates across regions make transportation particularly expensive. Retailers often provide prepaid return labels and expedited processing to meet customer expectations, further adding to the financial burden.

Regulatory requirements also add complexity. Federal and state laws regarding return policies, refund timelines, and disclosure requirements vary widely, requiring companies to navigate a challenging legal landscape. This often demands specialized expertise, increasing operational costs.

Return fraud is another significant issue in the U.S. market. In 2024 alone, U.S. retailers lost over $103 billion due to fraudulent activities like serial returners. With fraud rates doubling year over year, businesses relying on manual systems find it increasingly difficult to detect and prevent these losses.

These factors highlight the immense cost pressures in the U.S. eCommerce space, making efficient returns management critical for profitability. Addressing these challenges often requires leveraging advanced reverse logistics software to streamline processes and reduce costs effectively.

The Challenges of Reverse Logistics and the Cost of Returns

How Reverse Logistics Software Reduces Returns Costs

Reverse logistics software turns the typically expensive process of managing returns into a more efficient and cost-effective system that safeguards your profits.

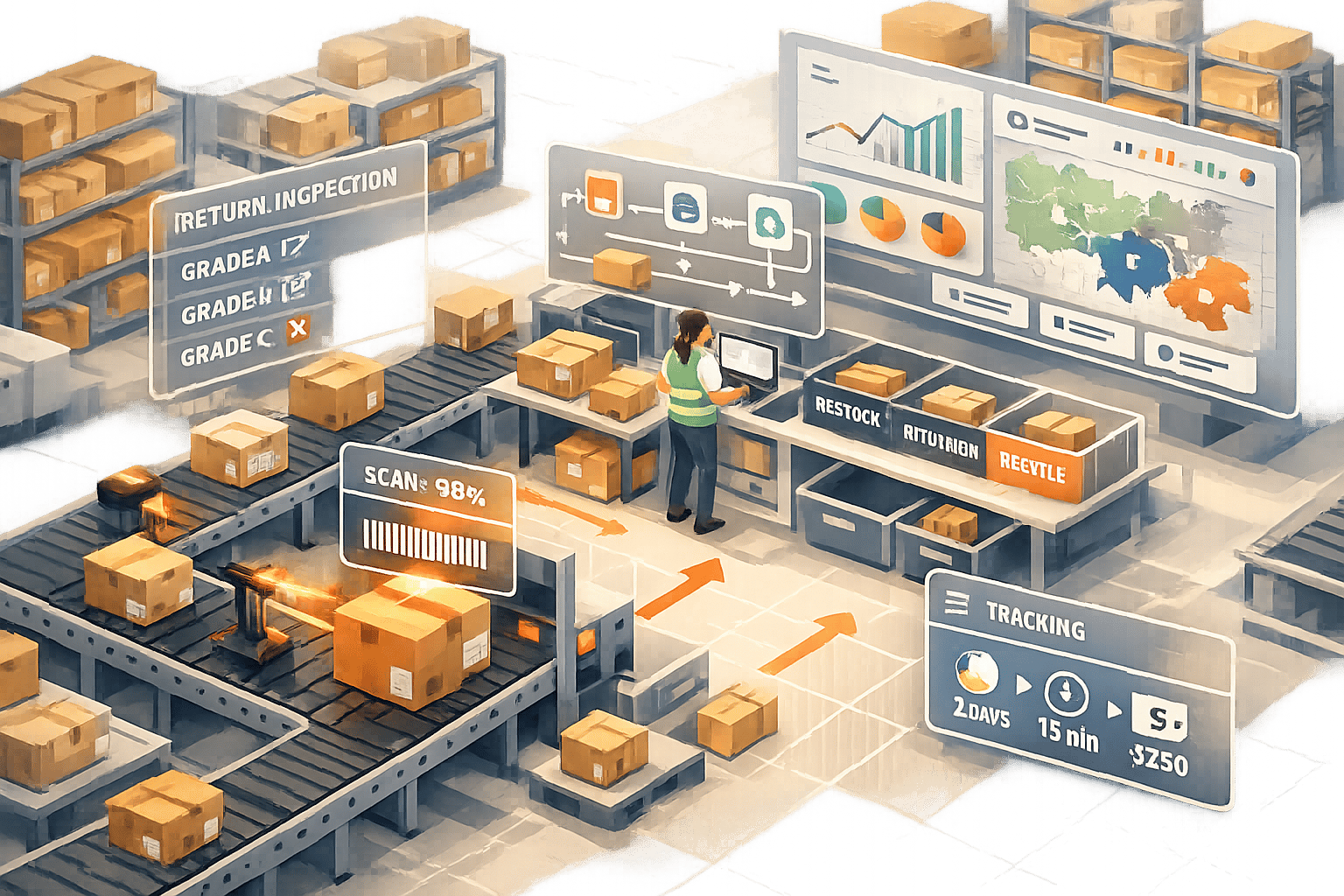

Automating Returns Workflows

One of the biggest advantages of reverse logistics software is its ability to automate manual tasks. Instead of relying on time-consuming processes like manually approving return authorizations, generating labels, or updating records, the software takes over and handles these tasks seamlessly.

For example, modern systems can automatically sort returned items based on their condition, update inventory records instantly, and trigger the appropriate next steps, such as restocking or initiating repairs. This level of automation eliminates common errors like incorrect inventory counts or misplaced refunds, which often require extra resources to fix.

Here’s a real-world example: A leading third-party logistics (3PL) provider reduced its return cycle from 12 days to just 4 days - a 67% improvement - while also cutting returns handling costs by 25%. These savings came from removing manual bottlenecks and reducing the labor hours needed for each return.

Automation also improves communication with customers, which reduces inquiries and boosts satisfaction. The same 3PL provider reported a jump in customer satisfaction among retail partners, increasing from 70% to 88% thanks to more transparent and efficient return handling.

But automation is just one piece of the puzzle. The software also tackles shipping costs, another major expense in returns management.

Optimizing Shipping and Carrier Selection

Shipping costs can eat up a significant portion of your returns budget, but reverse logistics software helps tackle this issue with real-time carrier comparisons and route optimization.

By integrating with multiple shipping partners, the software can dynamically choose the most cost-effective option for each return. It considers factors like the destination, package size, and delivery speed to find the best deal - saving money across all shipments.

Route optimization takes things a step further by consolidating returns into fewer shipments and selecting the most efficient paths back to processing centers. For instance, the software might route items to a nearby facility instead of a central hub, or combine multiple returns into a single shipment to reduce costs.

The data these systems generate also gives companies a strong position when negotiating with carriers. Armed with detailed metrics on shipping volumes, return patterns, and carrier performance, businesses can secure better rates and service terms. These negotiated savings add up over time, creating meaningful long-term reductions in transportation costs.

Recovery and Sustainability Programs

Beyond automation and shipping, reverse logistics software helps businesses recover value from returned items through smarter disposition strategies. Instead of defaulting to disposal or heavy discounting, the software uses automated decision-making to determine the best course of action for each product.

For instance, items in good condition can be quickly reintegrated into inventory, thanks to inventory reintegration workflows. This minimizes the time they spend sitting in storage, essentially turning them back into revenue-generating stock. Meanwhile, products that need minor repairs can be routed through automated repair workflows, allowing brands to recover significant value instead of writing off the entire cost. This is especially useful for industries like electronics and apparel, where small fixes can make a big difference.

The software’s focus on sustainability also resonates with environmentally conscious U.S. consumers. By tracking metrics on waste reduction and recycling efforts, companies can report on their progress toward a circular economy. This not only cuts waste disposal costs but also enhances brand reputation - a win-win for direct-to-consumer (DTC) brands that compete on both price and values.

Platforms like Forthmatch further amplify these benefits by connecting DTC brands with 3PL partners specializing in advanced reverse logistics. This combination of cutting-edge software and expert partnerships creates a comprehensive solution that reduces immediate processing costs while maximizing long-term value recovery opportunities.

sbb-itb-eb0f906

Choosing the Right Reverse Logistics Software

After achieving cost savings through automation and optimized shipping, the next step is selecting the right reverse logistics software. This choice is crucial for turning costly returns into efficient, streamlined processes. In 2024, U.S. retailers faced losses exceeding $103 billion due to inefficient reverse logistics and fraud, underscoring the importance of picking software with the right tools.

Key Features to Look For

The best reverse logistics software should offer:

- Returns tracking for real-time updates on item status.

- Automated workflows to classify returns by product type and condition.

- Analytics dashboards to identify trends and prevent fraud.

- Platform integrations with popular eCommerce systems like Shopify and WooCommerce.

Businesses using automation at this level have reported up to 50% faster returns processing while reducing labor costs. AI-driven features can assess whether items should be resold, repaired, or recycled, based on their condition and profitability. Additionally, seamless integration with other platforms ensures smooth data sharing and operational efficiency.

Once the right software is in place, the next step is collaborating with transparent third-party logistics (3PL) providers to further optimize savings.

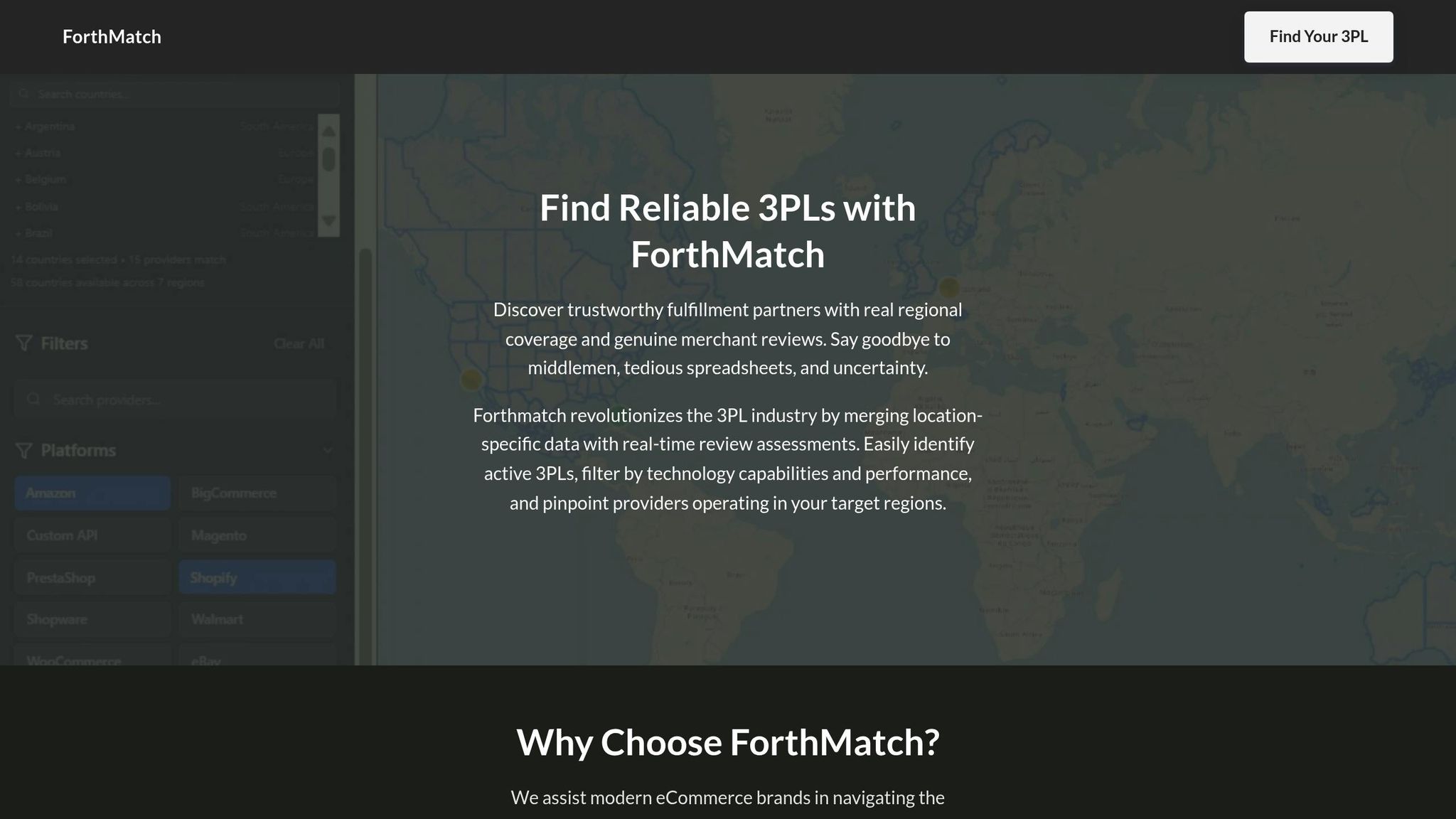

Finding Transparent 3PL Partners with Forthmatch

While advanced software is essential, teaming up with the right 3PL provider can take your reverse logistics strategy to the next level. More than two-thirds of businesses using 3PLs report noticeable savings in their operations. However, the process of identifying the right partner often gets bogged down by brokers, hidden fees, and lengthy negotiations.

Forthmatch simplifies this process. It offers a free, transparent directory of vetted 3PL providers specifically designed for direct-to-consumer (DTC) brands. Through Forthmatch, you can compare fulfillment partners based on delivery coverage, platform compatibility, pricing, and feedback from other merchants. Real-time service area maps show exactly where providers operate, while advanced filters help you pinpoint the capabilities you need.

By integrating with platforms like Shopify, Forthmatch identifies your key sales regions and matches you with 3PLs that serve those areas. It also allows direct communication with providers, cutting out intermediaries. This makes it easier to negotiate clear contracts and service levels that align with your goals.

Combining transparent 3PL partnerships with advanced software ensures better cost control and eliminates hidden fees, creating a more efficient reverse logistics operation.

Integration and Scalability Requirements

For a reverse logistics strategy to succeed, seamless integration and scalability are non-negotiable. Your software must integrate smoothly with existing systems while being scalable to handle business growth. Compatibility with ERP systems, warehouse management systems (WMS), and your eCommerce platform is key. Without proper integration, you risk inefficiencies like data silos and manual reconciliation that can derail operations.

Scalability becomes especially critical during peak seasons or periods of rapid expansion. Effective software should handle higher return volumes without requiring extra labor or causing bottlenecks. For example, large furniture retailers using ERP systems with reverse logistics features have successfully managed returns during high-demand periods while maintaining customer satisfaction.

The software should also adapt to fluctuating return volumes, avoiding fixed costs that don’t match actual needs. Integration with inventory and order management systems ensures accurate stock levels and quick restocking, reducing idle product time.

To ensure the chosen solution meets your needs, pilot test options with key stakeholders. This helps validate integration and performance. Additionally, clear communication with potential 3PL partners during this phase establishes expectations and service levels that align with your long-term growth plans.

Best Practices for Reducing Returns Costs

After choosing the right software and securing reliable 3PL partnerships, the next step is to fine-tune your processes to maximize cost savings. By focusing on data, streamlined workflows, and sustainable practices, you can cut costs while enhancing your brand image.

Track and Analyze Key Metrics

Keeping an eye on key metrics is critical for spotting inefficiencies in your returns process. For instance, tracking return cycle time helps you lower inventory holding costs and improve cash flow. Monitoring recovery rates - the percentage of returned items that can be resold or refurbished - can minimize unnecessary losses.

It’s also important to measure shipping costs per return to see if your carrier choices and routing are cost-effective. And don’t overlook fraud metrics: return fraud has become a major issue, doubling annually and costing U.S. retailers over $103 billion in 2024.

Reverse logistics software can centralize all this data, giving you a clear view of trends and patterns that manual tracking might miss. With these insights, you can make informed adjustments to reduce returns and associated costs, improving your entire workflow.

Improve Workflows and Prevent Fraud

Once you’ve gathered insights, use them to optimize your returns workflows. Automated sorting systems, for example, can classify returns by product type and condition in minutes, slashing labor costs tied to manual inspections. Real-time inventory updates allow for quicker restocking, so products don’t sit idle.

Automation can cut returns processing times by up to 50%, especially during peak seasons. These software-driven systems also improve accuracy by flagging items for inspection, identifying those ready for resale, and directing damaged goods to the right disposal or refurbishment channels.

Fraud prevention is another area where automation shines. For example, your system can flag suspicious behavior, like frequent high-value returns or refund requests without actual returns. This helps mitigate losses while keeping operations efficient.

Don’t forget to regularly review workflows and gather customer feedback. These steps can help you fine-tune processes and adapt to new challenges as they arise.

Use Sustainability for Cost Efficiency

Sustainability isn’t just good for the planet - it can also save you money. Your software can identify items that can be refurbished and resold instead of discarded. Products with minor cosmetic issues or missing parts can often be restored to sellable condition at a fraction of the cost.

Recycling programs are another way to cut costs, as they reduce disposal fees by reclaiming material value. Choosing sustainable carriers and optimizing transportation routes can lower both fuel costs and carbon emissions. Additionally, working with local refurbishment centers and recycling facilities can minimize transportation expenses for items that can’t be resold as-is.

Eco-friendly practices don’t just save money - they also build trust with your customers. When shoppers see that your returns process is handled responsibly, they’re more likely to feel confident buying from you, knowing their returns are managed with care for the environment.

Conclusion

Reverse logistics software is reshaping how DTC brands handle returns, especially as costs continue to climb. By automating workflows, optimizing shipping decisions, and providing real-time data insights, this technology transforms what was once a costly, manual process into an efficient, cost-saving operation. For example, automation has cut returns processing times by as much as 50%, leading to lower costs and faster inventory turnover. These improvements not only save money but also lay the groundwork for smoother operations in the long run.

Key Takeaways

The value of reverse logistics software goes far beyond cost reduction. Automation simplifies tedious manual tasks, speeds up restocking, and helps preserve resale value, all of which improve cash flow. Meanwhile, data analytics uncover patterns that can help reduce the volume of future returns.

Customer experience also gets a boost. Shoppers appreciate transparent tracking, quicker refunds, and hassle-free returns, which builds trust and encourages repeat purchases - fueling future sales growth.

There’s also an environmental upside. By identifying opportunities for refurbishment and recycling, this software reduces waste and recovers value from items that might otherwise be discarded. This appeals to eco-conscious consumers while protecting your bottom line - a win-win for brands.

Outsourcing reverse logistics to a 3PL provider can amplify these benefits. In fact, over two-thirds of businesses report significant cost savings when working with 3PLs. Their specialized expertise, advanced tools, and economies of scale make them a smart choice for managing returns more effectively.

Next Steps for DTC Brands

To get started, evaluate your current returns process to pinpoint inefficiencies and high-cost areas. Look for bottlenecks caused by manual tasks or gaps in visibility that could be addressed with the right tools.

When choosing reverse logistics software, prioritize systems that integrate seamlessly with your existing eCommerce and warehouse platforms. Features like automated workflows, real-time tracking, and robust analytics should be at the top of your list. Fraud prevention tools are also essential, given the rise in return fraud.

For the physical side of returns, consider partnering with a transparent 3PL provider. Platforms like Forthmatch simplify this process by offering a free directory of vetted providers. You can compare options based on delivery reach, platform compatibility, and real merchant feedback - without worrying about brokers or hidden fees. Their real-time service maps and direct contact features make it easy to find a 3PL that fits your needs.

"Our experience with Forthmatch was a game-changer. Thanks to their platform, we found a 3PL that perfectly fits our needs and saved $600 per month while gaining valuable visibility into our operations." - CLAIRE RASMUSSEN, CEO OF SOME COMPANY

Keep in mind that adopting reverse logistics software isn’t a one-and-done solution. Monitor metrics like return cycle times, recovery rates, and customer satisfaction to fine-tune your processes and adapt to market changes.

FAQs

How can reverse logistics software enhance the returns process and reduce costs for eCommerce brands?

Reverse logistics software simplifies the returns process for eCommerce brands, making it faster and more efficient. By automating tasks like generating return labels, updating inventory, and processing refunds, it saves time while minimizing errors. This streamlined approach not only cuts down operational costs but also enhances the customer experience with quicker, hassle-free returns.

Additionally, integrating this type of software provides businesses with insights into return patterns. By analyzing this data, companies can pinpoint recurring issues like defective products or incorrect orders, helping them reduce return rates over time. This proactive strategy not only lowers expenses but also boosts customer satisfaction.

What key features should I look for in reverse logistics software to reduce returns costs?

When choosing reverse logistics software, prioritize features that simplify returns and help manage costs efficiently. Key functionalities to look for include automated return processing, real-time tracking, and data analytics. These tools not only speed up the returns process but also provide insights to refine your operations. It's also crucial that the software integrates smoothly with your current eCommerce platform and supports flexible return policies to improve the customer experience.

For eCommerce businesses, resources like Forthmatch can make logistics planning easier. Forthmatch offers a global directory of vetted third-party logistics (3PL) providers, enabling you to compare options based on delivery coverage, pricing, and platform compatibility. This level of transparency helps you select the best partners to streamline your reverse logistics and keep costs under control.

How does reverse logistics software help reduce return-related costs and prevent fraud?

Reverse logistics software is a game-changer for businesses looking to reduce the costs tied to product returns. It simplifies key processes like return approvals, inventory restocking, and refund management by automating them. This not only saves time but also cuts down on errors and boosts overall efficiency.

On top of that, many of these tools come equipped with features designed to tackle return fraud. They can track return patterns, verify product serial numbers, and enforce stricter return policies. With these capabilities, businesses can better detect and prevent fraudulent activities, safeguarding their profits in the process.