- Reduce shipping distances: Shorter delivery routes mean fewer zones and lower costs - brands save 20–30% on last-mile expenses.

- Lower per-order costs: Regional 3PLs cut shipping costs to $3–$7 per order compared to $5–$10+ for in-house shipping.

- Avoid expensive shipping options: Faster standard delivery eliminates the need for costly expedited shipping.

- Share infrastructure and carrier discounts: Benefit from pre-negotiated rates and bulk shipping efficiencies.

Key takeaway: By placing inventory in regional warehouses and using tools like Forthmatch to track performance, DTC brands can cut costs and deliver faster without sacrificing quality.

Top 10 3PL Warehousing Benefits 🚀 Save Money & Scale Faster

How Regional 3PLs Lower Fulfillment Costs

Regional 3PLs (third-party logistics providers) offer several ways to trim fulfillment expenses. Key strategies include reducing shipping distances, strategically placing inventory, and leveraging bulk shipments.

Shorter Shipping Distances and Zone Skipping

The proximity-focused approach of regional 3PLs plays a big role in cutting costs. One standout method is zone skipping, where shipments are consolidated and sent to a regional hub before local carriers handle the final mile. This strategy helps avoid higher costs tied to long-distance shipping, like fuel surcharges (which account for 10–15% of shipping labels) and residential delivery fees ($4–5 per package).

Regional Warehousing and Inventory Placement

Storing inventory closer to high-demand areas is another way regional 3PLs reduce costs. By positioning goods in regional warehouses, brands minimize transportation expenses and last-mile delivery fees. Additionally, this setup reduces the need for expedited shipping and split shipments, which can pile on extra pick-and-pack charges. For instance, Walmart has shown that placing fulfillment centers near key customer hubs can significantly lower transportation costs while speeding up delivery times. However, managing multiple regional warehouses can increase complexity and inbound shipping costs, so it's essential to ensure order volumes justify these changes.

Bulk Shipments and Load Management

Regional 3PLs also cut costs by consolidating orders into bulk shipments. By maximizing truck capacity and combining shipments for clients in the same area, they lower the cost per package. These providers often secure carrier discounts by grouping deliveries headed in similar directions. Advanced tools - like route optimization, real-time tracking, and data analytics - further reduce transportation costs by as much as 10–20%.

Regional vs. National 3PL Cost Comparison

Choosing between regional and national 3PLs depends on your business needs and where your customers are located. Here’s a side-by-side look at how they compare:

| Feature | Regional 3PLs | National 3PLs |

|---|---|---|

| Cost | Lower for local and regional orders; reduced zone fees and fuel costs | Higher for cross-country shipments; may offer volume discounts |

| Flexibility | High; customized solutions for local markets | Moderate; standardized processes with limited customization |

| Delivery Speed | Faster for regional customers due to shorter transit times | Consistent nationwide coverage, though distant regions may take longer |

| Setup Complexity | Requires multiple partnerships for broader coverage | Typically involves one partnership for national reach |

| Hidden Fees | Possible split-shipment surcharges and multiple storage fees | Potential removal fees and migration costs |

For businesses with a concentrated customer base in specific regions, regional 3PLs often deliver better value. They offer competitive rates and adaptable solutions, with average B2C fulfillment costs projected to be around $3.25+ per order in 2025. On the other hand, brands with customers spread across the country might find centralized fulfillment through national 3PLs more efficient, even if it comes with higher per-order costs. This comparison underscores why regional 3PLs are often the smarter choice for businesses targeting specific markets.

Steps to Maximize Savings with Regional 3PLs

To truly cut costs with regional 3PLs, it's not just about choosing the right warehouse locations. It’s about digging into your data and fine-tuning your processes. Here’s how you can identify opportunities, streamline your operations, and keep fulfillment costs in check.

Use Order Data to Find Key Regions

Your order data holds the key to smarter warehouse placement. Dive into your shipping addresses, sales trends, and e-commerce heatmaps to uncover geographic clusters where most of your orders are coming from. For instance, if 60% of your orders are shipping to the Northeast, setting up a fulfillment center in that region can significantly reduce delivery times and shipping zones.

Don’t stop there - factor in seasonal trends and growth forecasts. If a particular area shows consistent year-over-year growth, it might make sense to invest in a regional center there. By moving inventory closer to your customers, you’ll not only lower shipping costs but also improve delivery speed. This type of analysis directly supports smarter inventory and packaging decisions.

Optimize Inventory and Packaging

Managing inventory efficiently can save you a fortune in storage fees and prevent funds from being tied up in unsold products. Use real-time tracking and automated replenishment tools to keep stock levels just right. Regularly review sales trends and seasonal demand to avoid overstocking or running out of key items. Remember, long-term storage fees can be 1.5–3 times higher than standard pallet rates.

Packaging is another area where savings can add up fast. Switching to right-sized boxes or lightweight materials can reduce dimensional weight charges. For example, replacing bulky boxes with mailer envelopes for smaller items could cut shipping costs by as much as 20%. Custom inserts and snug-fitting protective packaging not only prevent damage but also avoid wasting space, saving on materials and shipping.

Negotiate Better Regional Shipping Rates

Once you’ve optimized your inventory and packaging, it’s time to use that data to negotiate better shipping rates. Regional 3PLs often have strong relationships with local carriers, giving them access to discounted rates that individual brands can’t secure on their own. Use your shipping volume and regional focus as leverage in these negotiations. In many cases, regional providers can deliver 10–30% lower rates through consolidated carrier agreements.

When comparing rate cards, look for volume-based discounts and zone-specific pricing that reflects the shorter delivery distances of regional fulfillment. Also, push for all-inclusive pricing to avoid surprises like fuel surcharges or residential delivery fees. Sometimes, paying a slightly higher rate upfront is worth it if it means better service and fewer hidden costs.

Track 3PL Performance Regularly

After locking in competitive rates, keep a close eye on your 3PL’s performance to ensure those savings stick. Set key performance indicators (KPIs) like order accuracy, on-time delivery, and cost per order. Use real-time dashboards to identify and address inefficiencies quickly.

Establish service level agreements (SLAs) that align with your business goals and customer expectations, and monitor metrics such as processing speed, delay patterns, and fulfillment accuracy. If you notice a spike in late deliveries or errors, it’s time to reassess your warehouse processes or carrier partnerships.

Data is your best ally here. Track inventory turnover, shipping cost trends, and customer satisfaction across regions and 3PL partners. Tools like Forthmatch, which offer real-time tracking and SLA analytics, can simplify this process. For example, Gordon Belch, Co-Founder of vybey, shared that Forthmatch’s tracking insights saved his company $600 per month by providing a clear plan for operational improvements.

sbb-itb-eb0f906

Use Technology to Choose and Monitor Regional 3PLs

Technology has reshaped how businesses select and manage regional 3PLs, replacing outdated manual processes with data-driven tools. These tools not only streamline operations but also help keep fulfillment costs in check.

Track Performance with Real-Time Data and SLA Monitoring

Keeping tabs on fulfillment operations in real-time is crucial for spotting and addressing issues before they escalate. The most effective monitoring platforms track key metrics like order accuracy, on-time delivery, average fulfillment time, and inventory turnover. With instant access to this data, you can quickly spot trends and resolve bottlenecks.

Service Level Agreements (SLAs) gain new significance when paired with automated monitoring tools. Look for platforms that track important metrics such as maximum order processing times, minimum accuracy levels, and guaranteed delivery windows. Automated alerts can flag SLA violations, enabling rapid responses to potential problems.

Advanced tools go beyond surface-level metrics by offering root cause analysis. Instead of just noting delays, these tools identify whether issues stem from inventory shortages, processing inefficiencies, or carrier problems. This deeper insight allows you to collaborate with your 3PL partners to implement targeted solutions, ultimately reducing fulfillment costs. Platforms like Forthmatch leverage these capabilities to make selecting the right partners simpler and more effective.

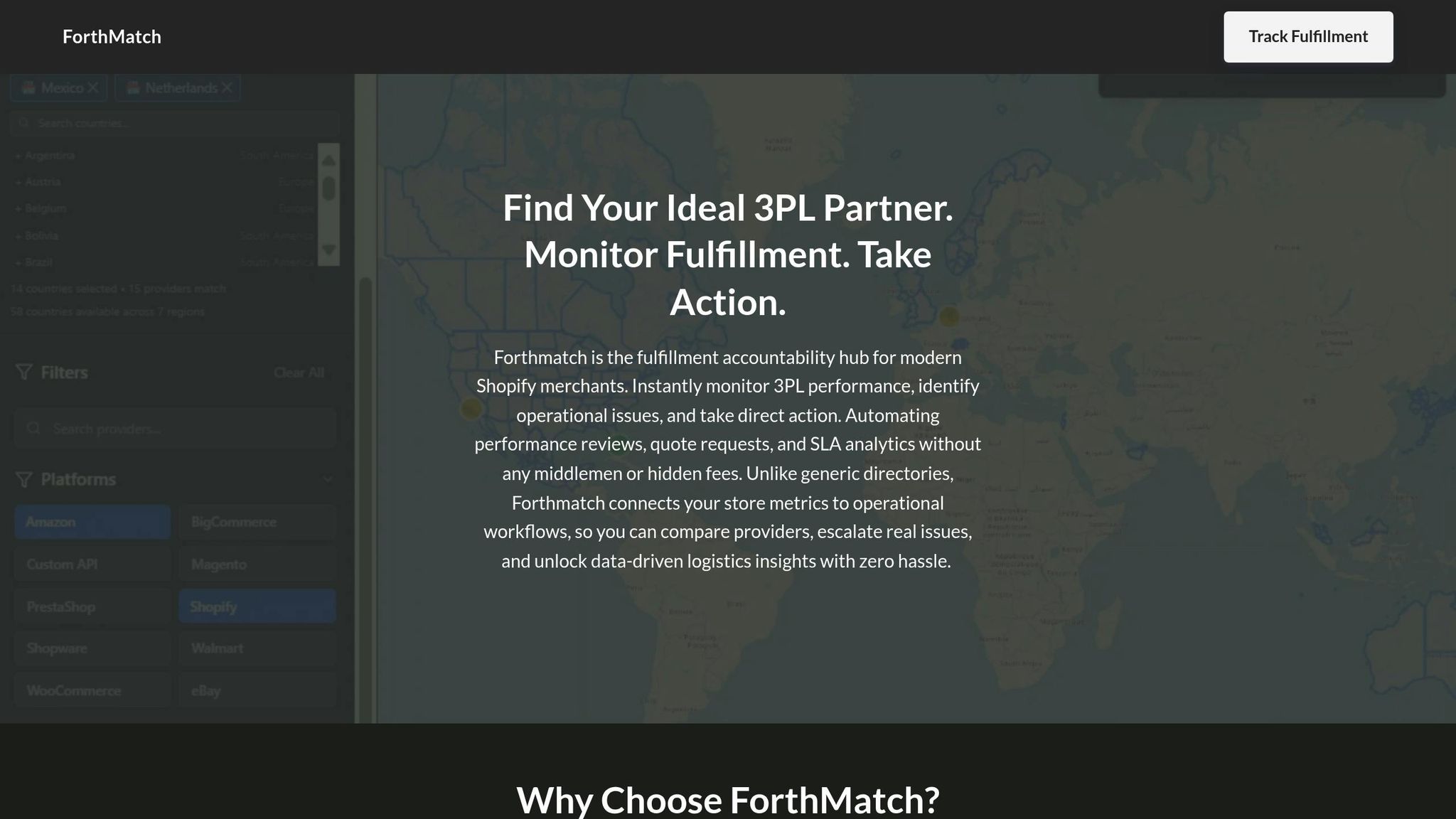

How Forthmatch Simplifies Regional 3PL Selection

Forthmatch makes choosing a 3PL provider easier by offering a free, global directory of vetted options tailored for DTC brands. The platform lets you compare providers based on delivery reach, integration compatibility, pricing, and real merchant feedback, all in one convenient location.

What sets Forthmatch apart is its commitment to transparency. Real-time service area maps show exactly where providers deliver, while feature-based filters help you narrow down your choices. Whether you need Shopify integration, same-day delivery, or specialized packaging, you can quickly find providers that meet your needs.

By connecting you directly with 3PL providers, Forthmatch eliminates brokers and hidden fees. This direct approach ensures fair pricing and clear communication, which is especially important for brands working with tight budgets.

Automate RFPs and Benchmarking with Forthmatch

Traditional RFP processes can be slow and inconsistent. Forthmatch simplifies this by automating quote requests, allowing you to send standardized proposals to multiple regional 3PLs at once. This makes it easier to compare providers objectively while saving significant time.

The platform’s benchmarking tools use aggregated performance data and merchant reviews to help you evaluate providers based on metrics that matter to your business, like delivery speed, accuracy, and customer service. Instead of relying on sales pitches, you can make informed decisions backed by real-world data.

"Forthmatch gave us daily, granular visibility into fulfillment delays and real accountability with our 3PL partner. The before/after tracking saved us $600/month and gave us a clear action plan to improve operations." - Gordon Belch, Co-Founder at vybey

Forthmatch also offers tools like the SLA Analytics Hub ($9/month), which provides ongoing performance tracking, instant alerts, and root cause analysis. For more structured collaboration, the 3PL Accountability Sessions ($50/session) allow you to review provider performance with clear metrics and actionable improvement plans. These features help ensure your 3PL partnerships remain effective long after the initial agreement.

With a pay-per-use pricing model, Forthmatch keeps costs flexible and transparent, so you only pay for the services you actually use.

Maintain Long-Term Cost Savings with Regional 3PLs

Achieving initial savings is just the beginning. The real challenge lies in sustaining those savings over time through careful management and smart growth strategies.

Manage Partnerships for Continuous Improvement

Long-term success with regional 3PLs depends on treating them as true partners rather than just service providers. This collaborative approach is critical for keeping costs under control. In fact, 64% of businesses report lower operating costs when working with a 3PL, but maintaining these savings requires ongoing effort and communication[6].

Schedule quarterly reviews with your regional 3PLs to evaluate performance metrics, address delays, and set actionable goals. These meetings should focus on hard data rather than vague feedback. Key metrics to monitor include order accuracy, on-time delivery rates, and average fulfillment costs per order. By keeping a close eye on these numbers, you can catch potential issues early and address them proactively.

The strongest partnerships often include shared dashboards where both parties can track real-time metrics. If problems arise, creating joint task forces allows for quick, collaborative solutions. Companies that work closely with their 3PLs to develop process improvement plans tend to resolve bottlenecks faster and adapt more easily to market shifts.

Regular reviews also give you leverage to renegotiate contracts, helping avoid hidden fees or unexpected charges that can erode your savings.

Expand Regional Networks as You Grow

As your business scales, expanding your regional 3PL footprint is key to maintaining cost efficiency. By analyzing order data, you can identify high-demand regions where adding fulfillment centers could reduce shipping distances and costs. This targeted approach ensures growth doesn’t lead to unnecessary complexity or added expenses.

Start small when entering new regions. Pilot programs allow you to test demand and service quality before committing to full-scale partnerships. For instance, if sales in the Midwest are surging, partnering with a regional 3PL in that area can significantly lower delivery times and shipping costs for customers in that region.

While regional expansion can cut shipping fees, it also adds complexity. Each new location increases inventory management challenges and the risk of split-shipment surcharges when orders are fulfilled from multiple warehouses. Expand only when the volume of orders justifies the additional overhead.

| Expansion Factor | Regional Approach | National Approach |

|---|---|---|

| Cost Structure | Lower for localized delivery | Higher for nationwide reach |

| Scalability | Easier for regional growth | Better for national expansion |

| Complexity | Lower with fewer nodes | Higher with multiple nodes |

| Customer Satisfaction | Higher for local customers | Variable, depends on reach |

As your network grows, maintaining visibility and control becomes even more critical.

Use Transparent Platforms for Long-Term Success

To ensure sustainable cost savings, leverage transparent platforms that provide real-time insights and eliminate hidden fees. These tools help you maintain control over operations and avoid unexpected cost increases.

Forthmatch is one such platform, offering features like real-time monitoring, automated benchmarking, and a pay-per-use pricing model. The SLA Analytics Hub ($9/month) provides instant alerts and detailed reporting to address issues before they escalate. Meanwhile, the 3PL Accountability Sessions ($50/session) are structured reviews designed to assess provider performance and create actionable improvement plans.

When it’s time to re-evaluate contracts, the Request Quotes feature ($50/session) allows you to compare your current providers against market rates, ensuring you remain competitive and can negotiate better terms.

By cutting out brokers and hidden markups, transparent platforms help you maintain direct relationships with your 3PL partners. This direct communication is invaluable for addressing performance concerns and securing contract improvements that align with your long-term cost-saving goals.

The pay-per-use pricing model also ensures you only pay for what you need, making it easier to keep costs manageable as your business evolves and your fulfillment requirements change.

Conclusion: Key Points for Reducing Fulfillment Costs

Regional 3PLs give DTC brands a powerful way to cut fulfillment costs while speeding up delivery times. The secret? Strategic inventory placement. By storing products closer to your customers, you can shrink shipping distances, avoid hefty zone surcharges, and reduce transportation expenses by as much as 10–20% through smarter routing and regional warehousing. These strategies, as outlined above, provide a clear roadmap for lowering costs without sacrificing efficiency.

Shipping consolidation services from regional 3PLs can also slash costs by up to 30% for small businesses. And for high-volume DTC brands, even small per-package savings can add up fast. These savings enable smarter, data-backed decisions that directly impact your bottom line.

To get the most out of your fulfillment strategy, use order data to identify high-demand areas. This allows you to strategically position inventory and calculate your total fulfillment costs, including hidden fees like fuel surcharges (10–15%), residential delivery fees ($4–$5 per label), and long-term storage penalties, which can be up to three times standard rates. A full understanding of these costs ensures you’re comparing actual expenses, not just surface-level rates.

Technology plays a key role in maximizing savings. Tools for real-time monitoring, automated benchmarking, and transparent cost comparisons help you avoid pitfalls, such as "budget" 3PLs that may come with hidden costs like high shrinkage allowances (up to 4% inventory loss).

For long-term success, treat your regional 3PLs as partners. Regular performance reviews, shared dashboards, and collaborative improvement plans can ensure consistent savings as your business scales. When the time is right, expand your regional network strategically, but only if your order volume justifies the added complexity. Combining strategic inventory placement, technology, and strong partnerships creates a reliable framework for reducing fulfillment costs.

Looking to lower your fulfillment expenses with regional 3PLs? Platforms like Forthmatch make it easy to compare vetted 3PL providers based on delivery reach, pricing, and real merchant reviews. With tools such as the SLA Analytics Hub ($9/month) for real-time tracking and Request Quotes ($50/session) for competitive benchmarking, you can make informed logistics decisions without dealing with brokers or hidden fees. Start optimizing your fulfillment strategy today.

FAQs

How do regional 3PL providers help DTC brands lower last-mile delivery costs?

Regional third-party logistics (3PL) providers can help cut down last-mile delivery costs by positioning their operations closer to where your customers are. With fulfillment centers located nearby, packages travel shorter distances, which often means quicker delivery times and reduced shipping costs.

On top of that, regional 3PLs typically offer flexible pricing structures designed to meet the unique needs of direct-to-consumer (DTC) brands. By concentrating on specific regional markets, they can streamline delivery routes and rely less on costly national carriers for every shipment. This not only saves money but also boosts customer satisfaction by ensuring faster deliveries.

What challenges can arise when managing multiple regional warehouses?

Managing multiple regional warehouses comes with its fair share of challenges. One of the biggest hurdles is dealing with operational complexity. Coordinating inventory levels, shipments, and returns across various locations demands well-organized systems and processes. If things aren't carefully managed, it can lead to frustrating inefficiencies - like one warehouse being overloaded with stock while another runs out.

Another issue is ensuring consistent service quality. Different regions might have varying delivery speeds, operational capabilities, or even customer expectations. These differences can directly affect the overall experience for your customers. On top of that, managing costs isn’t straightforward either. Expenses like labor, utilities, and transportation can differ widely depending on the location, making budgeting a real challenge.

To tackle these problems, businesses should look into advanced inventory management tools, set up clear and effective communication channels, and team up with trustworthy regional 3PL providers. For example, platforms like Forthmatch are a great resource for DTC brands, helping them connect with the right logistics partners to simplify operations and cut down on fulfillment costs.

How can Forthmatch help DTC brands optimize fulfillment with regional 3PL providers?

Forthmatch makes it easier for DTC brands to connect with the right regional 3PL partners. With tools to compare providers based on delivery areas, pricing, and service features, the platform ensures businesses find the best match for their logistics needs. Merchants can quickly filter options by region, services offered, and compatibility with their eCommerce platforms, creating a customized solution.

The platform also offers real-time service area maps and direct access to thoroughly vetted 3PL providers, cutting out unnecessary intermediaries and avoiding hidden fees. This level of transparency empowers brands to make smarter logistics choices, saving money and boosting efficiency.