3PLs (Third-Party Logistics providers) help DTC (Direct-to-Consumer) brands manage supply chain risks effectively. These risks, such as supplier delays, quality issues, or financial instability, can severely impact DTC brands due to their direct involvement in logistics and customer fulfillment. Here's how 3PLs reduce these risks:

- Diversified Supplier Networks: 3PLs work with multiple suppliers across different regions, minimizing reliance on a single source and mitigating disruptions from regional issues like natural disasters or political instability.

- Inventory Management: They use advanced forecasting tools to maintain optimal inventory levels and strategically place stock across multiple warehouses, ensuring availability even during disruptions.

- Real-Time Tracking: Technologies like RFID and IoT provide live updates on shipments, enabling quick responses to potential issues.

- Quality Control: Rigorous checks and compliance expertise ensure products meet standards, protecting brand reputation.

- Backup Plans: Contingency strategies, such as alternative suppliers and emergency inventory, enable swift action during disruptions.

DTC brands face unique challenges, including tight cash flow cycles, just-in-time inventory strategies, and high customer expectations. Partnering with the right 3PL provider is key to building a resilient supply chain. Platforms like Forthmatch simplify the selection process by offering vetted 3PL directories, trust scores, and real-time service maps.

Key Takeaway: 3PLs provide essential tools and expertise to reduce supplier risks, ensuring smoother operations, better customer satisfaction, and fewer disruptions.

Main Supplier Risks That Affect DTC Brands

Money and Payment Risks

Payment-related risks with suppliers can strain cash reserves and disrupt daily operations for DTC brands. The core issue often stems from a mismatch in the timing of cash outflows (payments to suppliers) and inflows (revenue from sales). Let’s break it down with a real-world example.

In September 2025, a DTC brand faced this exact challenge. They paid a 50% deposit of $5,000 on Day 0 for 1,000 units and settled the remaining $5,000 on Day 45. However, their sales didn’t kick in until Day 50, and the cash from those sales didn’t hit their accounts until Days 55–57. This left the brand navigating a cash gap of over 50 days.

These upfront payments lock up funds for extended periods, significantly lengthening the cash conversion cycle. As DTC brands grow, this extended cycle can put immense pressure on liquidity.

Supplier Risk I Managing Supply Chain Risk I Explainer Video

How 3PLs Reduce Supplier Risks

Third-party logistics providers (3PLs) act as essential partners for direct-to-consumer (DTC) brands, helping them navigate and mitigate supplier-related risks. Their infrastructure and expertise create safeguards that individual brands often can’t implement on their own.

Working with Multiple Suppliers

3PLs maintain a broad network of geographically dispersed suppliers, reducing reliance on any single source. If one supplier encounters issues like production delays or quality problems, 3PLs can quickly shift to alternative suppliers, ensuring uninterrupted operations.

This geographic diversity also protects against regional disruptions. For example, if a supplier in one country is affected by political instability or a natural disaster, 3PLs can redirect production to partners in unaffected areas. This multi-sourcing strategy significantly lowers the risk of operational downtime.

Additionally, 3PLs often negotiate better terms with suppliers due to their large purchasing volumes. These agreements can include more favorable payment schedules, quality guarantees, and priority production slots - advantages that individual DTC brands might struggle to secure on their own.

Managing Extra Inventory

Using advanced forecasting tools, 3PLs determine the optimal inventory levels for each product. By analyzing historical sales data, seasonal trends, and market conditions, they help brands maintain just the right amount of extra inventory.

This approach reduces financial strain for brands, as many 3PLs offer flexible payment terms. Some even provide consignment options, allowing brands to pay only after products are sold.

Strategically placing inventory across multiple fulfillment centers further minimizes risk. If one warehouse faces an issue, orders can be seamlessly fulfilled from another location, preventing delays. These inventory strategies are supported by real-time tracking systems, ensuring smooth supply chain operations.

Real-Time Tracking and Data

3PLs utilize technologies like RFID, GPS, and IoT sensors to monitor shipments from suppliers to fulfillment centers. These tools allow for immediate identification of potential problems. Predictive analytics further enhance this process by spotting trends that could indicate supplier reliability issues.

AI-powered demand forecasting adds another layer of precision. By analyzing factors such as weather patterns, economic shifts, and even social media trends, 3PLs can better predict inventory needs. This reduces the chances of stockouts or overstocking, while providing DTC brands with greater visibility and control over their supply chains.

Quality Checks and Rule Compliance

3PLs implement rigorous quality assurance programs to ensure that defective products don’t reach consumers. These programs include incoming inspections, random sampling, and detailed documentation of quality metrics. By catching issues early, they help maintain a brand’s reputation for reliability.

Navigating regulatory requirements can be especially challenging for DTC brands operating across states or internationally. 3PLs bring expertise in compliance, from FDA guidelines for health products to FTC labeling rules for consumer goods. They ensure all products meet necessary standards before they enter the fulfillment process.

Many 3PLs also hold certifications like ISO 9001 for quality management or industry-specific credentials. These certifications demonstrate their commitment to maintaining high standards, providing brands with added confidence that supplier risks are being handled effectively.

Backup Plans for Problems

Beyond diversified sourcing and inventory management, 3PLs develop contingency plans to address potential disruptions. These plans outline responses to various scenarios, such as supplier delays or major supply chain interruptions. They include alternative suppliers, emergency inventory locations, and clear communication protocols to keep brands informed.

When disruptions occur, 3PLs can act swiftly. Thanks to their relationships with multiple carriers, they can reroute shipments through alternative transportation networks. Backup inventory is also on hand to fill gaps during supplier transitions.

Speed is critical during supply chain disruptions, and 3PLs excel in this area. With dedicated teams monitoring supply chain health around the clock, they can detect and address issues faster than most brands could manage internally. This rapid response often determines whether a disruption remains a minor hiccup or escalates into a significant problem.

sbb-itb-eb0f906

Using 3PL Directories to Pick the Right Partner

After explaining how 3PLs help reduce supplier risks, the next step is finding the right partner to work with.

Why Picking the Right 3PL Matters

Choosing the right 3PL provider isn’t just about logistics - it can make or break your supply chain. A good match helps your business grow by improving order accuracy, cutting down on rework, and reducing return rates. These benefits protect your margins and improve overall operations. Plus, the right partner grows with you, adapting to new SKUs, additional sales channels, and shifting customer demands.

On the flip side, a poor choice can lead to hidden costs, such as damaged inventory, delayed shipments, or customer service headaches - all of which can harm your brand’s reputation. A careful selection process helps you avoid these pitfalls and ensures your supply chain stays strong.

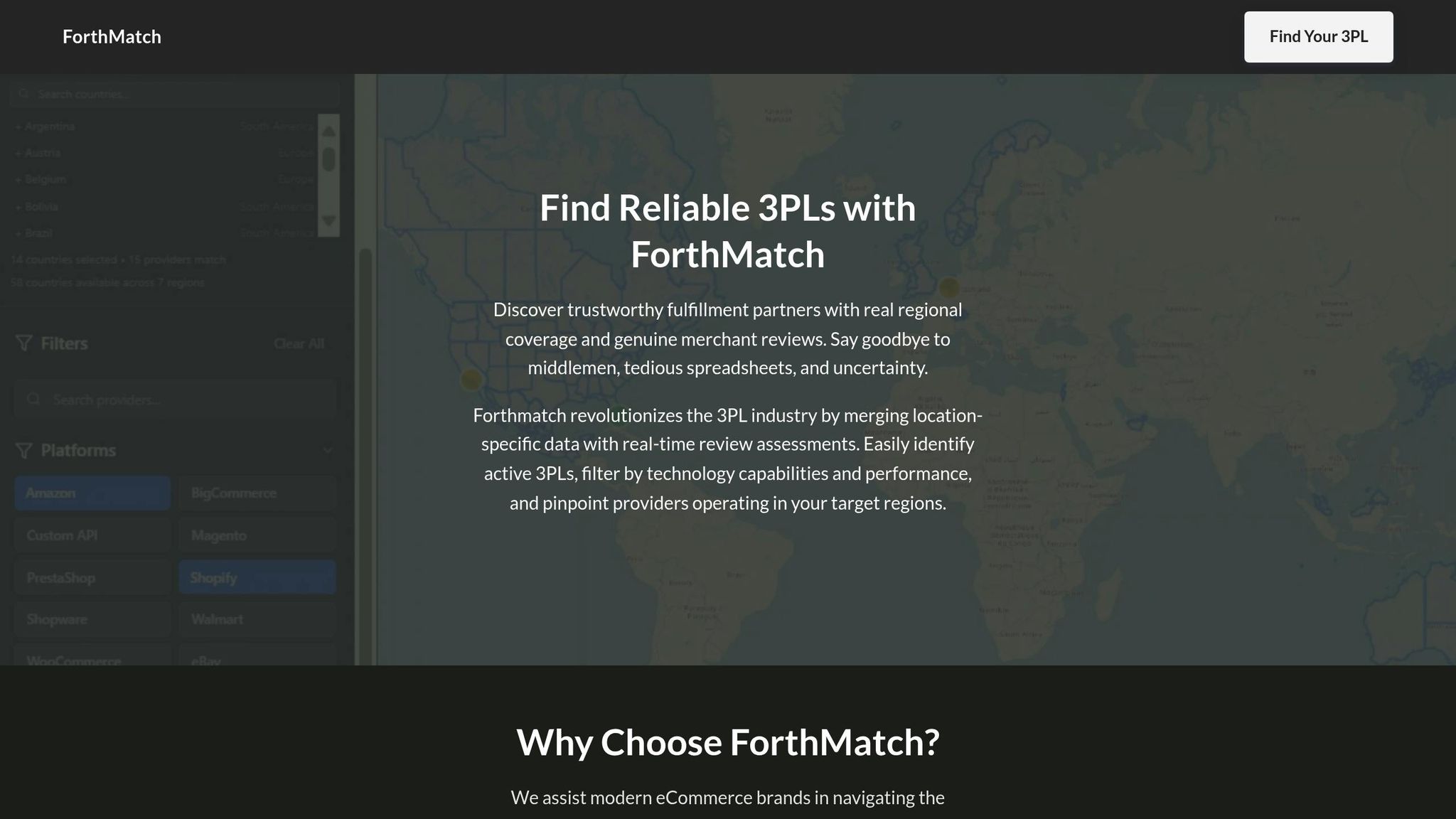

How Forthmatch Simplifies 3PL Selection

Forthmatch offers a free, global directory of pre-vetted 3PL providers, making it easier to find the right fit without dealing with middlemen or hidden fees. The platform features real-time service area maps that use isochrones and isodistances, giving you a clear picture of each provider’s delivery zones. Advanced filters let you narrow down options based on region, specialty, and platform compatibility.

One standout feature is Forthmatch's trust scoring system. It uses public reputation signals, domain credibility, and performance metrics to help you identify reliable providers before you even reach out. This data-driven approach minimizes the risks that could otherwise disrupt your supply chain and harm your brand.

Comparing 3PLs Based on Risk Factors

Selecting a provider is just the first step; evaluating risk factors is equally important. When assessing 3PLs, don’t stop at pricing or location. Forthmatch provides a structured framework to evaluate providers on key areas like growth alignment, technology integration, operational performance, pricing transparency, and geographic reach.

Geographic reach is especially critical when managing supplier risks. Forthmatch’s real-time service maps let you see how well a provider’s delivery zones match your customer base. Providers with multiple fulfillment centers are a safer bet, as they can maintain operations even if disruptions occur in one region.

Another key feature is platform compatibility filtering, which ensures seamless integration with your existing tech stack. This prevents data silos and visibility issues that could worsen supplier risks. Soon, Forthmatch will introduce community-sourced reviews and sentiment scoring, giving you even more insights into providers’ communication, problem-solving skills, and overall reliability.

Best Practices for Managing Supply Chain Risks

Once you've chosen a 3PL partner, the next step is to actively manage supply chain risks. This involves a continuous process of monitoring and adapting, using strategies that complement the risk mitigation tools your 3PL partner provides. Here's how to stay ahead.

Check for Risks Regularly

Supply chain risks are always evolving, so regular assessments are a must. Schedule quarterly reviews to evaluate your suppliers and your 3PL's performance. Use metrics like order accuracy, delivery times, and inventory turnover to measure effectiveness. Adjust your risk management strategies to reflect seasonal patterns and market changes. Dive into 3PL performance reports to spot recurring problems, such as shipment delays or inventory mismatches. These periodic reviews lay the groundwork for effective real-time monitoring.

Use Real-Time Data and Monitoring

Real-time data can revolutionize how you handle supply chain risks. Tools like GPS, RFID, and IoT provide instant updates on inventory levels, shipment progress, and potential disruptions. Surprisingly, only 31% of companies actively use real-time data today. Closing this gap can give you a major edge. For example, automated alerts from IoT sensors can flag issues like low stock levels, delays, or even temperature fluctuations in sensitive shipments. This kind of monitoring also allows for dynamic route adjustments and more precise delivery estimates.

Work Together on Backup Plans

Strong collaboration with your 3PL is key to effective contingency planning. Don’t just assume your provider has everything covered - work together to prepare for disruptions like natural disasters, supplier failures, or shipping delays. Develop and test these contingency plans regularly through simulations, ensuring they’re ready to handle real-world challenges. This proactive approach ensures quicker, more effective responses when disruptions occur.

Keep Up with Rule Changes

Regulations change frequently, and staying up-to-date is essential to avoid disruptions or fines. Work with your 3PL to review compliance updates monthly. Use tools like a compliance calendar to track deadlines for certifications, tax updates, and regulatory changes. Make sure your provider holds the necessary certifications for handling specific products, whether it’s hazardous materials, food, or medical devices. Keep detailed records of shipments, quality checks, and compliance activities to streamline audits and investigations.

Conclusion: Building Stronger Supply Chains with 3PLs

Teaming up with a 3PL can transform how brands manage their supply chains. With access to diverse supplier networks, strategic inventory solutions, and real-time visibility, companies can shift from simply reacting to problems to proactively preventing them. This means fewer stockouts, quicker recovery from disruptions, and - most importantly - happier customers who get their orders on time.

But the perks don’t stop at risk management. 3PLs offer cost advantages that individual brands often can’t achieve alone. They negotiate better shipping rates, maintain backup inventory across multiple locations, and handle the complexities of compliance - whether that’s dealing with hazardous materials or navigating international shipping regulations. Their infrastructure and expertise become an extension of a brand’s operations.

Of course, these benefits hinge on finding the right 3PL partner. That’s where transparent tools make all the difference. Forthmatch simplifies the process with real-time service area maps, access to vetted providers, and unbiased rankings - no broker fees, no hidden markups. Instead of wasting weeks chasing quotes or sitting through sales calls, DTC brands can quickly pinpoint 3PLs that align with their needs, from platform compatibility to delivery capabilities. This efficiency is critical in today’s ever-changing supply chain environment.

Looking ahead, supply chains will continue to face challenges from geopolitical shifts, climate concerns, and evolving customer demands. Resilient partnerships with 3PLs allow brands to stay agile and thrive in the face of these uncertainties. The real game-changer? Viewing logistics not as a cost to minimize but as a strategic tool that drives customer satisfaction and fuels growth.

FAQs

How can 3PLs help DTC brands address cash flow challenges with supplier payments?

When direct-to-consumer (DTC) brands team up with a third-party logistics provider (3PL), they can tackle cash flow challenges more effectively. One way 3PLs help is by simplifying payment processes. Many offer tools like automated billing and invoicing, ensuring suppliers get paid on time and with fewer mistakes. This not only keeps payments running smoothly but also strengthens relationships with suppliers.

Another benefit is how 3PLs often combine logistics fees and order payments into a single system. This makes it easier for brands to manage their funds and allocate resources where they’re needed most. By reducing administrative headaches and improving cash flow, 3PLs give growing DTC brands a stronger financial foundation.

How do 3PLs use technology to improve tracking and supply chain visibility?

Third-party logistics (3PL) providers use cutting-edge tools to improve tracking and make supply chains more transparent. Technologies like RFID tags, GPS, IoT sensors, and barcode systems enable real-time updates on shipments and inventory. Mobile devices further streamline communication and ensure accurate, up-to-the-minute information.

On top of that, many 3PLs harness the power of AI and machine learning to process vast amounts of data. By identifying trends and offering actionable insights, these technologies help businesses minimize delays, stay informed, and make more strategic logistics decisions.

Why is selecting the right 3PL partner essential for DTC brands, and how does Forthmatch help?

Choosing the right 3PL partner is crucial for direct-to-consumer (DTC) brands. It helps reduce supply chain risks, streamlines logistics, and ensures reliable delivery - factors that are essential for building customer trust and staying ahead in the market. On the flip side, poor logistics decisions can result in delayed shipments, inventory headaches, and unhappy customers, all of which can damage your brand’s reputation.

Forthmatch makes this process easier. It’s a free and transparent platform where DTC brands can compare thoroughly vetted 3PL providers. You can evaluate them based on real-world performance, delivery coverage, pricing, and service offerings. By cutting out brokers and hidden fees, Forthmatch gives businesses the tools to make smarter, quicker logistics decisions that align with their specific needs.