3PLs (third-party logistics providers) can help businesses reduce storage costs by offering flexible pricing, advanced inventory management, and strategic warehouse locations. Instead of paying for fixed warehouse space, 3PLs charge based on actual usage, helping businesses save money. Here’s how they do it:

- Flexible Pricing Models: Options like per-pallet, per-cubic-foot, or per-SKU pricing let you pay only for the space or inventory you use.

- Shared Facilities: Costs like rent, utilities, and staffing are distributed across multiple brands, making storage more affordable.

- Inventory Optimization: Advanced systems reduce handling times, flag slow-moving products, and improve space efficiency.

- Geographic Distribution: Warehouses closer to customers reduce shipping costs and delivery times.

- Automation: Technology like warehouse management systems (WMS) and robotics cut labor costs and improve accuracy.

How 3PLs calculate your storage fees

3PL Storage Pricing Models Explained

Grasping how 3PLs set up their storage fees is key to managing your costs. The pricing model you choose can significantly affect your monthly expenses, especially as your inventory levels shift.

Types of Storage Pricing Models

Per-pallet pricing involves a flat monthly fee for each pallet your inventory occupies. This model is ideal for businesses storing large quantities of similar products. However, if your inventory includes smaller items or products of varying sizes, you might end up paying for unused pallet space.

Per-cubic-foot pricing charges based on the exact volume of your inventory, measured in cubic feet. This option is great for brands with irregularly sized products or smaller inventories that don’t fill entire pallets. You’re only billed for the space you actually use, making it a more precise approach.

Per-SKU pricing is based on the number of unique products (SKUs) you store, rather than the physical space they occupy. This can be a cost-effective choice for brands with a wide variety of products that don’t require much individual storage space. However, it may become costly if you maintain large quantities of each SKU.

Some 3PLs offer hybrid pricing models, combining elements of these structures. For instance, you might pay a base fee per SKU along with additional charges for cubic footage if you exceed a certain inventory threshold.

Benefits of Flexible Pricing Options

Choosing the right pricing model can lead to significant savings, depending on your product mix and inventory patterns.

- Cubic-foot pricing is often a great fit for brands like fashion or electronics companies that deal with products of varying sizes and seasonal inventory shifts. You avoid paying for unused pallet space, which keeps costs aligned with your actual storage needs.

- Per-pallet pricing is well-suited for businesses selling large, bulky items like furniture or appliances. It provides a predictable monthly expense and ensures you’re fully utilizing each pallet position.

- Per-SKU pricing works best for brands with extensive product catalogs but low inventory volumes per item. Beauty brands, for example, often benefit from this model since their products typically require minimal storage space.

Many 3PLs allow businesses to switch between pricing models as their needs evolve. This flexibility ensures you can adapt your storage costs as your product lineup or inventory volumes change over time.

Pricing Model Cost Comparison

| Pricing Model | Best For | Monthly Cost Example | Pros | Cons |

|---|---|---|---|---|

| Per Pallet | Bulky items, consistent inventory | $25-$40 per pallet | Predictable for large products | Inefficient for smaller items |

| Per Cubic Foot | Mixed product sizes, seasonal brands | $0.50-$1.20 per cubic foot | Pay only for space used | Requires more complex calculations |

| Per SKU | High-variety, low-volume inventory | $5-$15 per SKU per month | Simple for diverse product lines | Expensive with high quantities |

The cost differences between models can be striking. For instance, a beauty brand with 50 SKUs might spend $250-$750 monthly using per-SKU pricing. If those products are densely packed, cubic-foot pricing could cost $400-$800 instead. Meanwhile, a furniture company storing 10 large items on 5 pallets would pay $125-$200 with per-pallet pricing, compared to $600-$1,000 under cubic-foot pricing.

Additionally, many 3PLs offer discounts for long-term storage but may apply premium aging fees for inventory that sits idle for more than 90 to 180 days. This encourages businesses to maintain efficient inventory turnover. Up next, we’ll dive into how inventory management strategies can help you keep storage costs under control.

Inventory Management to Lower Storage Costs

Third-party logistics providers (3PLs) can help businesses cut down on storage costs by speeding up inventory turnover. Let’s break down how strategies like demand forecasting, cross-docking, and location-specific methods work together to keep storage expenses in check.

Demand Forecasting and Dead Stock Removal

3PLs rely on advanced forecasting tools to predict demand and identify slow-moving products. This allows businesses to take action - whether through pricing adjustments, promotions, or discontinuing certain items - before excess inventory becomes a problem.

Managing dead stock is another crucial service. When products reach the end of their lifecycle, a dependable 3PL can step in to coordinate liquidation sales, donation programs, or even proper disposal. This proactive approach prevents businesses from racking up storage fees on items that no longer generate revenue.

Additionally, automated reorder points, based on sales trends and lead times, ensure that stock levels remain balanced. These systems help avoid overstocking, which can quickly inflate storage costs.

By streamlining these processes, businesses can not only save on storage but also improve cash flow by turning inventory into revenue more efficiently.

Cross-Docking and Direct Fulfillment

Cross-docking eliminates long-term storage by sorting and repackaging shipments for immediate delivery. This keeps items moving, shifting costs from storage fees to shorter-term handling and processing charges.

Direct fulfillment takes this efficiency even further. In this model, suppliers ship products straight to the 3PL facility, where orders are processed immediately for delivery to customers. This reduces the need for extended storage and lowers handling costs. It’s particularly useful for new product launches or limited-time promotions, helping businesses avoid the pitfalls of overstocking.

For these strategies to work seamlessly, businesses need a 3PL partner with strong coordination skills - one capable of synchronizing incoming shipments with outgoing orders and maintaining high standards of quality control.

Storage Method Cost and Efficiency Comparison

Traditional warehousing works well for businesses with stable inventory and predictable costs. However, alternatives like cross-docking and direct fulfillment stand out for their ability to reduce storage time and adapt quickly to changing market demands. These methods not only cut storage fees but also allow businesses to respond faster to customer needs and trends.

That said, the success of these approaches depends on thorough planning, reliable supplier relationships, and precise forecasting and coordination by the 3PL partner. When executed well, these integrated strategies help businesses keep storage costs lean, enhancing overall efficiency and profitability.

Using Smart Warehouse Locations

Placing warehouses strategically can significantly reduce storage and shipping costs for DTC (direct-to-consumer) brands. When third-party logistics (3PL) providers position their facilities closer to customers, delivery times get shorter, and long-haul transportation expenses drop. This approach lays the groundwork for exploring the specific advantages of proximity, network design, and cost savings.

Proximity to Major Customer Areas

When it comes to shipping, location is everything. Warehouses near major metropolitan areas can cut shipping costs compared to those located farther away. Shorter distances mean lower fuel costs, fewer handling fees, and faster delivery times. Regional fulfillment takes it a step further by spreading inventory across multiple locations to meet local demand, avoiding the pitfalls of overstocking a single facility. This setup is especially helpful for temperature-controlled goods, as it shortens cold-chain routes, reducing both spoilage risks and the need for costly specialized transportation.

Nationwide and Global Networks

A network of strategically placed warehouses across the U.S. allows businesses to allocate inventory based on regional demand. This distributed model offers more flexibility than relying on a single, centralized warehouse. During busy seasons, inventory can be shifted to balance capacity and avoid extra storage fees. In slower periods, operations can consolidate to save on costs.

On a global scale, strategically located hubs simplify customs processes and reduce per-unit shipping costs, making international operations more efficient.

Warehouse Location Impact Comparison

| Location Strategy | Average Shipping Cost | Delivery Time | Storage Flexibility | Peak Capacity |

|---|---|---|---|---|

| Single Central Warehouse | Higher | Longer | Limited | Prone to congestion |

| Regional Network (multiple hubs) | Moderate | Faster | High | Better capacity balance |

| Nationwide Network (widespread) | Lower | Fastest | Very high | Effectively distributed |

Well-placed warehouses also reduce the need for costly expedited shipping. When inventory is closer to customers, ground shipping becomes more efficient, cutting out the need for premium rush services. Distributed networks handle seasonal demand spikes by spreading the load across multiple facilities, avoiding last-minute storage or transportation surcharges. Techniques like zone skipping - where packages bypass intermediate sorting centers and head directly toward their destinations - further trim handling costs and speed up delivery times.

sbb-itb-eb0f906

Technology's Role in Cost Reduction

Technology plays a critical role in cutting costs within 3PL operations, building on efficient inventory and location strategies. By streamlining warehouse processes, modern tech reduces storage expenses and improves overall operational efficiency. For direct-to-consumer (DTC) brands, this translates to better accuracy, optimized use of warehouse space, and lower costs.

Warehouse Management Systems (WMS)

Warehouse Management Systems (WMS) are the digital nerve center of today’s fulfillment operations, managing everything from the moment an item arrives to when it ships out. These systems provide real-time inventory tracking, reducing the time spent searching for items and automating inventory counts. With insights into inventory levels, locations, and movement patterns, WMS ensures better space utilization and fewer errors.

By analyzing factors like product size, turnover rates, and seasonal demand, WMS can suggest efficient storage layouts to maximize available space. This not only boosts efficiency but also sets the stage for deeper automation, which we’ll dive into next.

Automation and Data-Driven Adjustments

Automation tools, such as robotic pickers and conveyor belts, take over repetitive tasks like moving items between storage zones and packing areas. These systems work around the clock, cutting down on manual labor and improving accuracy. For DTC brands, this means fewer mistakes and faster order processing.

Data analytics add another layer of efficiency. By examining past sales trends and seasonal demand spikes, 3PLs can optimize storage allocation and predict future needs. This proactive approach helps reduce storage fees and handling costs. Predictive maintenance tools also play a role, monitoring equipment like forklifts and conveyors to catch issues before they cause downtime.

Machine learning further enhances operations by analyzing past workflows. It can refine picking routes, improve staff scheduling, and streamline processes - all contributing to lower storage and handling expenses. Together, automation and data-driven insights create a more efficient, cost-effective warehouse environment.

Selecting the Right 3PL Partner

Picking the right third-party logistics (3PL) partner can make or break your storage and shipping strategy. A poor choice can lead to unexpected fees and rising costs, while a well-chosen partner can streamline your operations. Let’s dive into the qualities that matter most when evaluating potential 3PL providers.

Key Qualities of an Effective 3PL Partner

Transparent pricing is non-negotiable. Look for providers that clearly outline all fees, from storage and handling to labor and technology costs. Avoid those who give vague or incomplete estimates. The best partners provide a detailed breakdown, so you’re never caught off guard by hidden charges.

Flexible pricing models are essential if your business experiences seasonal fluctuations. Some 3PLs offer flat monthly rates, while others use tiered pricing that scales with volume. Choose a model that aligns with your inventory patterns and growth plans to ensure your costs stay manageable.

Technology integration is a game-changer for smooth operations. Your 3PL should integrate seamlessly with your eCommerce platform to enable real-time inventory updates and automated order processing. This ensures your supply chain stays efficient and error-free.

Strategic geographic coverage is another critical factor. The location of a 3PL’s warehouses can significantly impact your shipping costs and delivery times. Providers with facilities near your key markets can help you reduce last-mile delivery expenses and improve customer satisfaction.

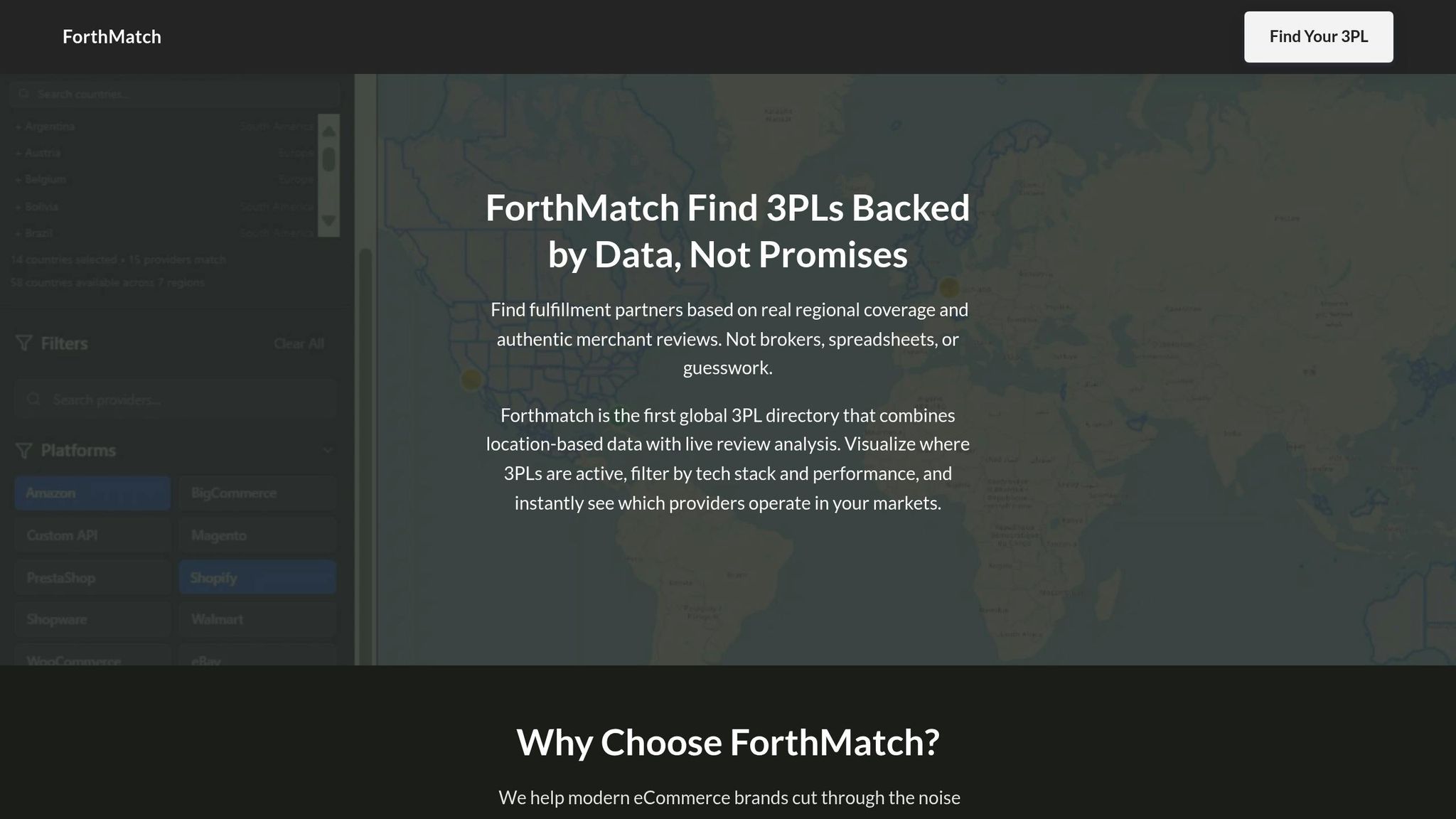

By focusing on these qualities, you can simplify the selection process and avoid costly mistakes. Forthmatch, for example, offers a streamlined approach to finding the right 3PL partner.

How Forthmatch Simplifies 3PL Selection

The traditional process of selecting a 3PL provider often involves time-consuming quotes, broker fees, and limited visibility into the provider’s capabilities. Forthmatch eliminates these hurdles by offering a free, user-friendly directory of vetted 3PL providers tailored to direct-to-consumer (DTC) brands.

With real-time service area maps, Forthmatch provides visual tools to assess delivery coverage. These maps display delivery zones within 30–60 minutes of key regions, helping you quickly identify providers with warehouses ideally placed to serve your target markets.

The platform also enables direct communication with providers, cutting out middlemen and their added costs. This direct connection ensures you receive unbiased information and can negotiate terms without worrying about hidden referral fees.

An intuitive filtering system allows you to narrow down your options based on criteria like platform compatibility, regional coverage, and provider specialties. This saves time and ensures you focus only on providers that meet your specific needs.

Finally, community-sourced reviews and performance data give you a clearer picture of each provider’s reliability and cost-effectiveness. Feedback from other DTC brands helps you avoid providers with hidden issues and empty promises.

3PL Evaluation Factors Comparison

| Factor | High Priority | Medium Priority | Low Priority |

|---|---|---|---|

| Clear Pricing | Detailed fee breakdown with no hidden costs | Some clarity but minor ambiguities | Vague pricing with hidden charges |

| Flexible Pricing Models | Matches inventory cycles and seasonal trends | Partially adaptable with occasional gaps | Fixed pricing, no flexibility |

| Technology Integration | Real-time connection with major eCommerce platforms | Basic integration with occasional delays | Manual processes, frequent issues |

| Geographic Coverage | Warehouses near key customer regions | Adequate coverage with some limitations | Limited network, high delivery costs |

Conclusion: Reducing Storage Costs with 3PLs

The right 3PL provider can transform storage expenses into a competitive advantage by combining flexible pricing models, smart inventory management, and strategic warehouse locations. These elements work together to cut costs and enhance efficiency.

Effective inventory management plays a significant role in reducing storage expenses. By leveraging demand forecasting and cross-docking, a skilled 3PL minimizes the time products sit in storage. Advanced warehouse management systems further optimize space usage, ensuring you only pay for what you truly need. When paired with warehouses strategically located near key customer markets, these efficiencies also lower shipping costs.

Automation and real-time inventory tracking add another layer of savings. These tools prevent overstocking, reduce errors, and enable just-in-time fulfillment, keeping products moving and minimizing storage dwell times.

Strategic geographic placement completes the cost-saving strategy. A 3PL with a well-distributed network allows you to position inventory closer to customers, cutting down storage times and shortening delivery distances. This proximity not only trims last-mile delivery costs but also improves customer satisfaction by speeding up delivery times.

Selecting the right partner is essential. Transparent pricing, seamless technology integration, and a strong track record help distinguish reliable 3PLs from costly missteps. Platforms like Forthmatch simplify this process by offering access to vetted providers, real-time service maps, and community reviews - without hidden fees or broker markups.

When pricing, technology, and location align, you gain a lean, scalable operation that keeps costs in check and performance high.

FAQs

What’s the best 3PL storage pricing model for my business?

Choosing the right 3PL storage pricing model comes down to understanding your inventory size, storage requirements, and how consistent you need your budget to be. Here are some of the most common models to consider:

- All-Inclusive Rates: This option bundles all services into one fee, making it a great choice if you prefer steady, predictable monthly costs.

- Fixed Monthly Fees: With this model, you pay a flat rate regardless of how much you use, making it ideal for businesses with consistent storage needs.

- Hybrid Models: A combination of fixed fees and charges based on usage, offering flexibility if your inventory levels tend to fluctuate.

Take a close look at what matters most to your business - whether it’s cost consistency or the ability to adjust to changing needs. Working with a dependable 3PL provider can simplify this decision and even help you save on storage costs over time.

How can a 3PL with well-placed warehouses help reduce costs and improve efficiency for my eCommerce business?

Why Strategically Located Warehouses Matter for Your eCommerce Business

Teaming up with a 3PL that operates warehouses in prime locations can be a game-changer for your eCommerce operations. When your inventory is stored closer to your main customer base, you can cut down on shipping distances, trim transportation costs, and speed up delivery times. The result? Happier customers and fewer expenses tied to lengthy shipping routes.

Warehouses situated near major transportation hubs also simplify your supply chain. They make it easier to manage stock levels and respond quickly to shifts in market demand. This kind of setup not only reduces delays but also supports growth, allowing your business to scale efficiently while keeping operational costs under control.

How can partnering with a 3PL provider and their technology help reduce my storage costs?

Partnering with a 3PL provider equipped with advanced technology can help trim your storage costs in meaningful ways. Tools like real-time inventory tracking and warehouse management systems (WMS) allow you to fine-tune stock levels, sidestep overstocking, and boost order accuracy. This means you’ll need less storage space and can avoid expensive mistakes.

On top of that, automation takes efficiency up a notch by streamlining operations and reducing labor costs. With tighter inventory control and quicker stock turnover, your business can cut down on storage expenses while enhancing supply chain performance - saving both time and money in the process.