Last-mile delivery - the final step in getting a package to your doorstep - can make up 53% of shipping costs. For international orders, this process gets even more complex due to customs, documentation, and varying address formats. That’s where third-party logistics providers (3PLs) step in.

Key takeaways:

- Challenges: Customs delays (43% of businesses struggle), address errors (73% of consumers face delivery failures), and multi-carrier handoffs.

- Solutions by 3PLs:

- Use regional hubs and local warehouses to cut costs and speed up deliveries.

- Consolidate shipments to save 25–30% on transportation.

- Automate customs processes to reduce delays by up to 50%.

- Offer real-time tracking with IoT devices and AI.

- Emerging tech: Drones, autonomous robots, and AI-driven route optimization are reshaping delivery.

Choosing the right 3PL involves evaluating their global reach, cost transparency, and ability to handle returns efficiently. With the right partner, businesses can reduce costs, improve delivery times, and enhance customer satisfaction.

How 3PLs Optimize Cross-Border Last-Mile Delivery

Third-party logistics providers (3PLs) are transforming cross-border last-mile delivery with smart strategies that bring products closer to customers, cut down on handling steps, and speed up customs processes. These methods create a foundation for further cost and time savings through practices like shipment consolidation and streamlined customs management.

Regional Fulfillment Hubs and Local Warehousing

To reduce shipping times and costs, 3PLs rely on regional hubs and local warehouses. For instance, shipping an item from the U.S. to Europe can range from $20 to $50 per package. However, storing inventory in local warehouses significantly reduces these costs and shortens delivery times.

Studies show that 68% of online shoppers abandon their carts because of high shipping fees or slow delivery. By offering 2-day or 3-day delivery to international customers, regional hubs address these concerns. Warehouses strategically located near key transportation networks - like highways, ports, and airports - simplify both inbound and outbound logistics. They also handle many customs-related tasks upfront, smoothing the overall process.

For businesses aiming to expand globally, partnering with 3PLs that operate hubs in major regions such as Europe, North America, and Asia is essential. Warehouse locations are chosen based on factors like proximity to target markets, access to transportation infrastructure, local shipping regulations, and even regional weather risks.

Cross-Docking and Consolidation Points

Localized inventory goes hand-in-hand with cross-docking, a practice that consolidates shipments to maximize cost savings. By grouping shipments at cross-docking centers, transportation expenses can drop by 25–30%, making it easier to implement just-in-time distribution models.

This approach allows businesses to adapt quickly to changing market demands. For example, some Canadian retailers have cut inventory costs by up to 15% while improving product availability on shelves by consolidating deliveries from multiple suppliers. For cross-border shipping, consolidation points also standardize shipments, optimize picking and packing, and provide the flexibility needed to adjust distribution strategies as demand fluctuates.

Customs Clearance and Documentation Management

Navigating customs is one of the most complex aspects of cross-border delivery, and it’s an area where 3PLs shine. Their expertise in customs clearance and documentation ensures compliance with international trade laws. These providers take care of the entire paperwork process, including accurate classification of goods, duty payments, and preparing essential documents like invoices, certificates of origin, and bills of lading.

With automated systems, 3PLs streamline customs clearance and minimize errors. Customs delays can cost businesses millions due to supply chain disruptions each year, so efficient management is critical. Experienced 3PLs maintain strong relationships with customs officials and use pre-clearance strategies to avoid unnecessary delays. By working closely with customs brokers, they reduce miscommunications and ensure smoother operations.

These combined efforts create a seamless approach to global last-mile delivery, addressing logistical challenges while keeping costs and delays to a minimum.

Technology That Powers Cross-Border Last-Mile Delivery

Technology is reshaping how cross-border last-mile deliveries are handled, offering real-time visibility and automation that simplify the complexities of international shipping. Modern third-party logistics providers (3PLs) are leveraging cutting-edge tools to streamline the movement of packages across borders, giving businesses and consumers greater control and transparency throughout the delivery process.

Real-Time Tracking and IoT Integration

Real-time tracking has become a non-negotiable feature for cross-border deliveries. In fact, 70% of consumers see tracking as a key factor when deciding where to shop online. To meet this demand, 3PLs use advanced tracking systems that offer detailed updates on a package’s location and condition. IoT devices like GPS sensors, temperature monitors, and shock detectors ensure packages are monitored every step of the way.

Take JUSDA’s China-Europe Express Rail, for example. It uses IoT sensors to provide real-time shipment tracking while integrating AI to speed up customs clearance. Additionally, tools like API integrations and GPS-powered geofencing send automated alerts when shipments reach critical checkpoints, allowing for proactive management of delivery schedules and customer updates. With the IoT logistics market expected to grow significantly, this technology is set to play an even bigger role in the future.

AI and Automation in Customs and Delivery Processes

Artificial intelligence is transforming some of the toughest parts of cross-border logistics - especially customs clearance. Countries using AI have slashed average customs clearance times by up to 55%, while AI systems that automate data validation can reduce these durations by 30–50%. For instance, Waytron Logistics Limited used AI to analyze historical customs data and real-time congestion reports, cutting customs delays by 43% in just six months.

"It doesn't just predict - it recommends pre-emptive action. That's the real power."

- Leo, operations manager

AI’s impact doesn’t stop at customs. AIDocBuilder, for example, automated 80% of customs paperwork for a global provider, reducing invoicing time from 10 minutes to just 5 seconds and saving $3.2 million annually. Companies like C.H. Robinson are using generative AI to handle email inquiries and booking requests, automating over 10,000 transactions daily. Route optimization powered by AI has also proven to lower logistics costs by up to 15% while improving service levels by 65%. For businesses navigating international shipping, AI acts as a compliance expert, as Erin, the founder of a direct-to-consumer (DTC) wellness brand, aptly put it:

"It's like having a compliance veteran riding shotgun on every shipment."

- Erin, founder of a DTC wellness brand

These advancements are setting the stage for a new era in last-mile delivery solutions.

New Last-Mile Fulfillment Technologies

Emerging technologies are redefining what’s achievable in last-mile delivery, complementing the strategic hubs and consolidation methods already used by 3PLs. For example, Walmart has completed over 6,000 drone deliveries in under 30 minutes and plans to use its 4,700 stores as fulfillment hubs. Meanwhile, autonomous delivery robots are gaining traction. Starship Technologies’ robots are already making deliveries in urban neighborhoods and on college campuses, and Wing, a subsidiary of Alphabet, is running commercial drone deliveries in the US, Australia, and Finland.

These innovations align with growing consumer expectations for faster and more eco-friendly delivery options. Hyperlocal fulfillment centers, often automated micro-warehouses, bring inventory closer to customers, enabling same-day or even hour-specific delivery windows. When paired with AI-driven demand forecasting - which can boost accuracy by 10% to 75% - these centers significantly enhance delivery speed and efficiency.

However, integrating these technologies isn’t without challenges. 3PLs must navigate regulatory hurdles, infrastructure gaps, and customer acceptance. Still, early adopters are already seeing the benefits. For instance, Amazon’s AI systems optimize inventory placement, allowing 60% of Prime deliveries in major US cities to arrive within a single day. This blend of AI, strategic warehousing, and automation underscores how technology is revolutionizing cross-border last-mile delivery.

Solving Common Cross-Border Last-Mile Problems

Cross-border last-mile delivery comes with its own set of challenges that can disrupt even the most well-thought-out logistics plans. Issues like mismanaged carrier handoffs and unexpected costs can quickly eat into profit margins. To tackle these hurdles, third-party logistics providers (3PLs) have developed effective strategies that help businesses stay on track.

Managing Carrier Handoffs and Service Inconsistencies

When packages switch between carriers during cross-border delivery, the risks of delays, damage, or even loss increase significantly. This is especially true when shipments involve multiple carriers with different service standards. To counter this, 3PLs build robust carrier networks that span air, ocean, and ground transport. By maintaining pre-negotiated agreements with a variety of carriers, they secure better pricing and more reliable service. This setup is crucial as consumer expectations evolve - 90% of consumers now anticipate delivery within two to three days.

To further enhance reliability, advanced tracking systems and unified platforms provide real-time visibility, ensuring smooth communication between international and domestic carriers. Additionally, 3PLs often recommend working with regional carriers to add flexibility and secure competitive rates.

These strategies not only improve delivery reliability but also simplify financial and administrative processes.

Simplifying Invoicing and Cost Management

Cross-border shipping often involves complicated fee structures that can turn a profitable sale into a financial headache. To simplify this, 3PLs use consolidated invoicing systems that bundle all shipping-related expenses into a single, transparent bill. This reduces administrative workload and makes cost management more straightforward.

Moreover, 3PLs leverage their negotiating power to keep shipping rates in check. As GlobalTranz explains:

"3PLs help keep shipping costs manageable by negotiating carrier rates and advising shippers on how to minimize fees and surcharges."

Advanced logistics systems also play a key role, automating price calculations and highlighting cost-saving opportunities. For example, these systems can flag shipments nearing weight thresholds that trigger higher fees or suggest alternative routes to avoid peak-season surcharges. Clear contracts and regular performance reviews ensure that 3PLs consistently deliver on cost-efficiency goals.

Handling returns efficiently is another critical piece of the puzzle for cross-border operations.

Handling Returns and Reverse Logistics

Managing international returns is tricky, thanks to varying customs rules, inconsistent return policies, and high shipping costs. In Southeast Asia, for instance, e-commerce return rates in 2022 ranged between 15% and 20% - more than double the rate of in-store sales. Notably, 83% of surveyed consumers said they’d increase their online purchases by at least 30% if returns were smoother. With global returns valued at nearly a trillion dollars annually, effective reverse logistics is essential.

To address these challenges, 3PLs rely on the "5 R's" of reverse logistics: Returns, Recapture, Remanufacturing, Reuse, and Recycle. Automation helps speed up the return process while reducing errors, and clear return policies improve the overall customer experience. Advanced inventory systems also allow returned items to be quickly reintegrated into sellable stock.

Zulfiqar Haider Shah, a Supply Chain Expert and Consultant, emphasizes the role of automation:

"Automation has not only expedited the return authorization and restocking process but also provided our customers with a more transparent and streamlined process. This has directly contributed to improved customer satisfaction, as returns are handled more swiftly, and customers receive timely updates throughout the process."

Similarly, Orlemyr Sousa da Silva, Logistics Specialist at CNH Industrial, highlights how data can transform returns:

"Detailed analysis of return data allows for identifying trends and opportunities for improvement, from product quality to marketing strategies. By partnering with a strategic warehouse partner, companies not only optimize their return processes but also transform a potentially costly activity into a valuable source of data for strategic decision-making."

In addition, smart 3PLs use Foreign Trade Zones to minimize duties and taxes on inbound returned goods and implement advanced tracking systems to provide real-time visibility throughout the returns process.

sbb-itb-eb0f906

Choosing the Right 3PL Partner for Cross-Border Success

Selecting the right third-party logistics (3PL) provider can determine the success or failure of your international expansion. Beyond overcoming logistical challenges, the right partner ensures smooth global operations. With countless providers claiming to offer flawless global fulfillment, it's essential to cut through the marketing noise and focus on what truly matters for your business.

Key Factors to Consider When Evaluating 3PL Providers

Strategic geographic presence is a critical consideration. Look for providers with established operations at key borders and inland locations. This ensures they can handle customs clearance efficiently and offer flexible distribution options once your goods arrive at their destination.

For example, a 3PL with facilities in both Laredo, Texas, and Nuevo Laredo, Mexico, can process shipments much faster than one that depends on third-party partners to manage border crossings.

LTL consolidation capabilities set top-tier providers apart. True less-than-truckload (LTL) consolidation for cross-border shipments optimizes trailer space, reduces mileage, and minimizes handling. This not only lowers costs but also decreases the risk of damage during transit.

Bilingual staff is another key asset, especially when operating in multiple countries. Miscommunication can lead to shipment delays or customs errors, particularly in regions like Mexico, where clear communication is vital to avoid costly mistakes.

Technology integration should be a top priority. Ensure your 3PL offers advanced tools such as transportation management systems (TMS), warehouse management systems (WMS), and real-time tracking. These systems should integrate seamlessly with your existing tech stack, providing full visibility across the supply chain - not just within the 3PL's operations.

Cost transparency is essential to protect your margins. Insist on a detailed breakdown of all costs, including base rates, fuel surcharges, and customs fees. Hidden charges can quickly erode the savings you expect from outsourcing.

Scalability is another critical factor. A provider that handles 1,000 orders per month efficiently may falter when your volume grows to 10,000. Confirm their capacity limits and expansion plans to ensure they can keep up with your growth.

Industry-specific experience can be a game-changer. Whether you're dealing with temperature-sensitive goods, hazardous materials, or high-value electronics, a 3PL with expertise in your product category will better navigate regulations and unique requirements.

With these factors in mind, streamlining the search for the right 3PL becomes much easier.

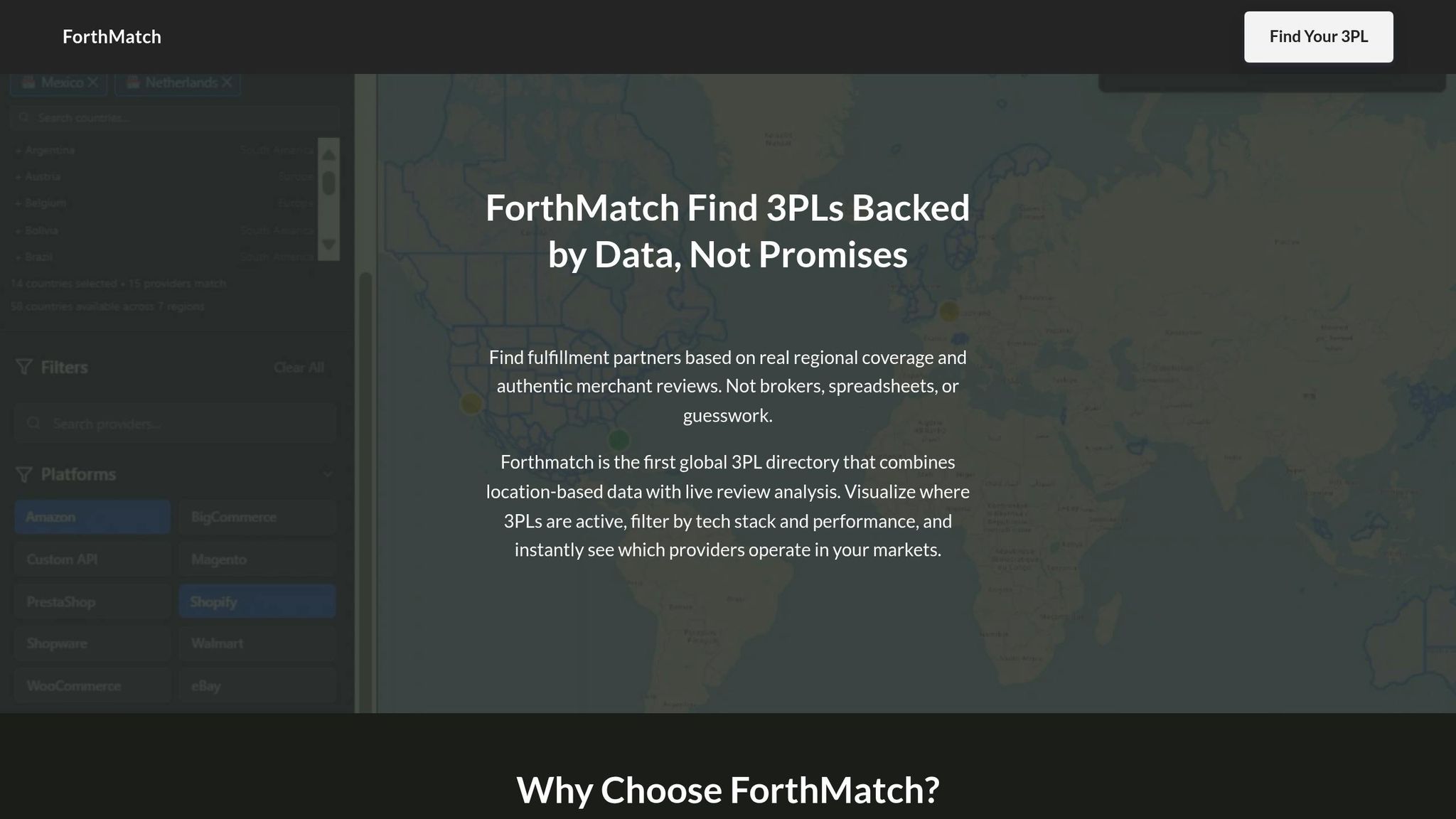

How Forthmatch Simplifies 3PL Selection

Traditional methods of choosing a 3PL - like lengthy RFP processes and multiple demo calls - can be cumbersome and inefficient. Forthmatch offers a faster, data-driven alternative to help you find providers that meet your specific needs.

Service area visualizations provide a clear picture of each 3PL's delivery reach. Forthmatch's regional footprint analysis shows exactly which areas are covered by a provider's warehouses, offering real operational data instead of vague claims about "global reach".

Market-based matching eliminates guesswork. By connecting your Shopify store to Forthmatch, you can automatically load the regions and countries you sell to. The platform then identifies fulfillment providers with proven operations in those areas, ensuring you're only considering 3PLs that can serve your customers effectively.

Filtering by technology and capabilities saves time by narrowing down options. You can filter 3PLs based on platform integrations, shipping zones, order volume requirements, and category expertise. This ensures you won't waste time evaluating providers that don't align with your business needs.

Reputation analysis through reviews offers insight into real-world performance. Forthmatch aggregates sentiment data from sources like Google and Trustpilot to give you a detailed picture of each provider's reliability, responsiveness, and overall trustworthiness.

Direct contact options cut out intermediaries and their fees. Forthmatch allows you to contact 3PLs directly, bypassing brokers, quote forms, and paywalls. As Forthmatch puts it:

"We help modern eCommerce brands cut through the noise and find fulfillment partners that actually serve their active regions. With clarity, confidence, and data to back it up."

Data-Driven Decision Making for 3PL Selection

Choosing the right 3PL requires focusing on performance metrics that directly impact your business. Key performance indicators (KPIs) like delivery times, order accuracy, cost efficiency, and customer satisfaction should guide your decision-making process.

Shipping accuracy is non-negotiable. The best providers maintain shipping accuracy above 99%. For instance, Red Stag Fulfillment achieved a 99.993% accuracy rate in 2024, with less than 0.01% inventory shrinkage. Tony Runyan, Chief Client Officer at Red Stag Fulfillment, emphasizes:

"Shipping accuracy should be a top priority for 3PLs. Everybody loses if our partners' customers don't receive orders on time and in full."

On-time delivery rates are equally important. While a 95% rate might be acceptable, exceptional providers aim for 99-100%. For cross-border operations, consider additional challenges like customs delays and carrier handoffs.

Cost benchmarking helps you evaluate pricing. A 2025 survey found that the average pick-and-pack cost for 3PLs is $3.25 for B2C and $4.85 for B2B. Use these figures to gauge whether a provider's rates align with industry standards.

Transparency and access to data are vital for ongoing optimization. Your 3PL should provide regular performance reports and grant you access to supply chain data. This allows you to identify trends, address issues proactively, and collaborate on improvements.

Establish clear expectations upfront, including service levels, performance metrics, and KPIs. Regular monitoring and quality checks ensure consistent performance, while open communication channels help address concerns quickly. A solid 3PL partnership can significantly boost your global success, especially when paired with tools like Forthmatch to guide your decision-making process.

Conclusion

Cross-border last-mile delivery comes with its fair share of challenges, but the right third-party logistics (3PL) partner can transform these obstacles into opportunities. By utilizing regional fulfillment hubs, simplifying customs clearance, and integrating advanced technology, 3PLs make international shipping more efficient and manageable.

Here's a key point to consider: last-mile delivery can account for as much as 53% of total shipping costs. E-commerce businesses that collaborate with specialized 3PLs have seen delivery times drop by an average of 24%, while on-time delivery rates have improved by 13%. And with 84% of shoppers saying they’re unlikely to return to a brand after a single poor delivery experience, it's clear that optimizing last-mile logistics is about more than just saving money - it's about safeguarding your brand's reputation.

Choosing the right 3PL is essential to achieving these results. Factors like a strong geographic presence, transparent pricing, and expertise in customs management and carrier coordination should guide your decision. Companies like Forthmatch simplify this process by offering data-driven insights into providers' service areas, technological capabilities, and merchant reviews - cutting out the need for lengthy RFPs and avoiding unnecessary broker fees.

A solid partnership with a capable 3PL doesn’t just improve delivery times and cut costs - it also frees you to focus on your core business while leaving the complexities of international logistics to the experts. As customer expectations for faster and more transparent delivery continue to rise, a dependable 3PL becomes a critical factor for staying competitive in global markets.

FAQs

How do 3PLs streamline customs clearance for cross-border last-mile deliveries?

How 3PLs Simplify Customs Clearance

Third-party logistics providers (3PLs) take the headache out of customs clearance by managing essential paperwork like commercial invoices and customs declarations. Their expertise ensures shipments comply with international regulations, reducing the risk of costly mistakes.

What’s more, 3PLs often collaborate with customs brokers and maintain strong relationships with customs authorities. This helps them navigate inspections efficiently, cutting down on delays that can slow your supply chain.

Another advantage? Many 3PLs calculate duties and taxes ahead of time. This proactive approach speeds up border processing, so shipments move through faster. By addressing potential issues early and tapping into their global logistics know-how, 3PLs make cross-border deliveries smoother and more predictable.

How does technology improve the speed and reliability of cross-border last-mile delivery?

Technology is reshaping cross-border last-mile delivery by making it faster and more dependable. Tools like AI-powered route optimization, real-time tracking, and visibility platforms are helping reduce delays, lower the chances of lost packages, and ensure deliveries arrive as expected. These advancements are streamlining the process and improving the overall experience for customers.

On the horizon, autonomous vehicles and delivery robots are showing promise in revolutionizing last-mile logistics. While these technologies are still in development, they have the potential to significantly improve efficiency and reliability, offering a glimpse into a future of quicker and more seamless cross-border shipping.

What should businesses look for when choosing a 3PL provider for cross-border last-mile delivery?

When choosing a 3PL provider for cross-border last-mile delivery, it's crucial to prioritize factors like reliability, global network reach, and expertise in international logistics. A dependable provider should have a solid grasp of customs procedures, regulatory requirements, and delivery schedules to ensure smooth operations.

It's also important to evaluate whether the provider offers scalable solutions, integrates seamlessly with your existing technology, and provides clear and upfront pricing. Features such as real-time tracking, robust infrastructure, and a strong history of handling cross-border shipments can make a significant difference. Partnering with the right 3PL can streamline your operations and enhance customer satisfaction for international deliveries.