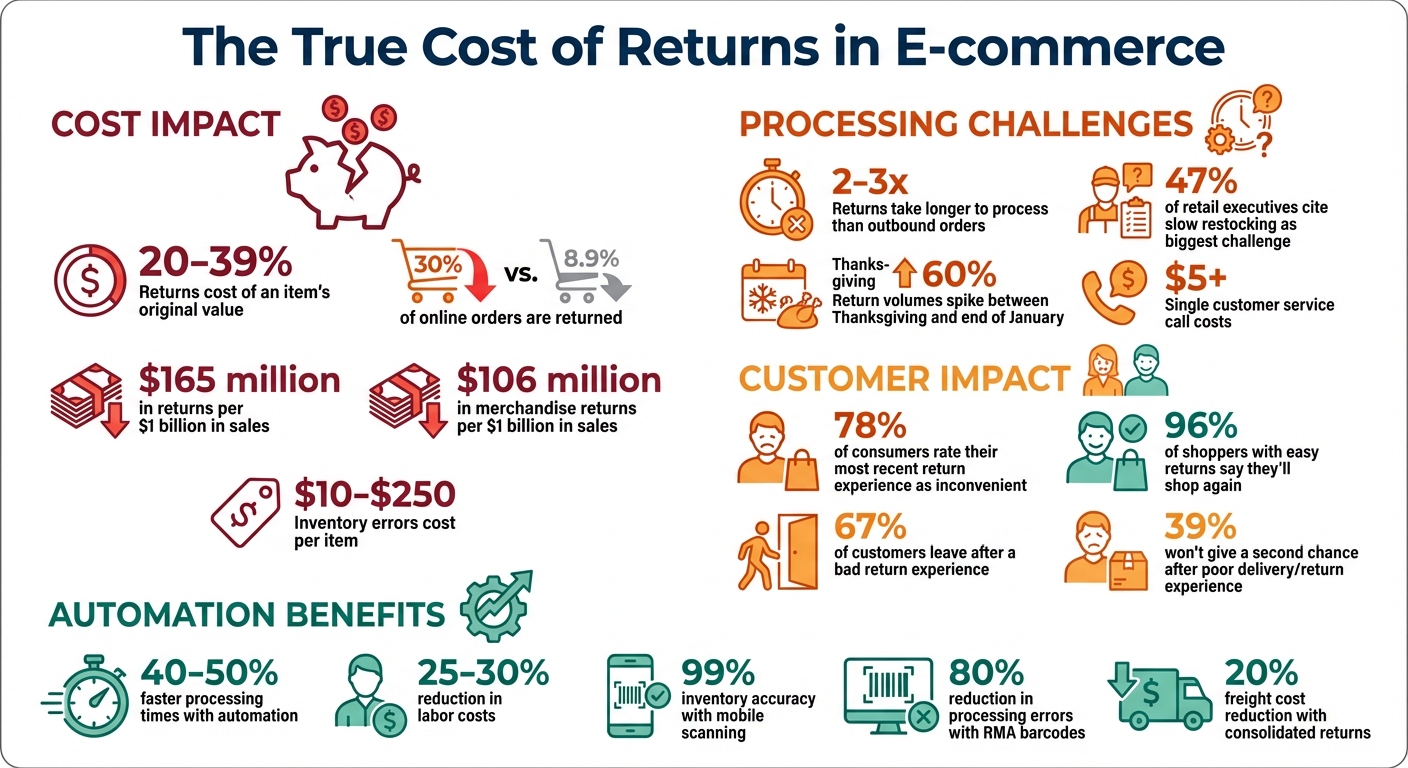

When it comes to managing e-commerce returns, third-party logistics (3PL) providers often face challenges that can hurt your business. Returns are costly, time-consuming, and prone to errors, with expenses eating up 20–39% of an item's value. Delays in processing, poor tracking, and inconsistent quality control can frustrate customers and damage your brand. To avoid these pitfalls, here's what you need to know:

- High Costs: Returns add labor, transportation, and storage expenses, costing $165 million per $1 billion in sales.

- Processing Delays: Refunds and restocking can take up to 3x longer than outbound orders, especially during peak seasons.

- Limited Visibility: Poor tracking systems lead to misplaced items, inventory errors, and lost sales opportunities.

- Quality Issues: Inconsistent grading of returns can result in defective items being resold, damaging customer trust.

Solutions: Use automated systems like RMA barcodes, set clear SLAs with your 3PL, and adopt real-time tracking tools to improve efficiency. Platforms like Forthmatch can help monitor 3PL performance, ensuring faster processing, better inventory accuracy, and fewer errors.

Returns management doesn't have to drain your profits - choose the right 3PL, leverage automation, and track their performance to turn returns into a smoother process.

The True Cost of Returns: Key Statistics for E-commerce Businesses

Why Is Returns Management Vital for Supply Chains?

High Reverse Logistics Costs

Reverse logistics can take a hefty toll on your budget. Beyond the usual outbound expenses, it places additional strain on various operational areas. For instance, processing a single return can cost anywhere from 20% to 39% of the item's original value and requires twice the labor compared to shipping an outbound order. To manage these costs effectively, you need to identify the key factors driving them.

What Drives These Costs

The costs start piling up the moment a return is initiated. Unlike outbound shipments, which move in predictable, high-volume batches, returns trickle in unpredictably and often in uneven "lumpy" volumes. Each returned item must go through a slow, manual grading process, which adds to the workload. In fact, 47% of retail executives cite slow restocking as their biggest challenge.

Warehouse congestion makes things worse, especially during times of global warehouse shortages. Returned goods clog up valuable space, disrupting the flow of outbound shipments. Seasonal items pose an additional risk - if they aren't processed quickly enough, their value diminishes. Miss the holiday season, for example, and you might end up with heavy markdowns or even liquidation.

Return fraud adds another layer of complexity, creating inefficiencies that delay processing and stretch resources even thinner. On top of that, something as simple as a single customer service call about a return can cost $5 or more. These challenges highlight the importance of understanding the underlying cost drivers to implement effective solutions.

How to Lower Costs

To combat the high costs tied to sporadic returns and labor-intensive processes, you can adopt several strategies. Start by tracking key metrics like cost per return and return-cycle time (the time from receiving a return to restocking it). Automation is another game-changer - automated sorting systems can remove manual bottlenecks and reduce new warehouse staff onboarding time to just 1–2 days.

Consider centralizing your returns in a dedicated area or facility, separate from outbound operations, to reduce warehouse congestion. You can also negotiate with carriers to consolidate returned parcels instead of shipping them individually. Some retailers are already leveraging third-party drop-off points or locker networks, cutting freight costs by as much as 20%.

Finally, streamline the grading process with handheld apps that guide inspectors and automatically categorize items for resale, refurbishment, or disposal. The quicker you can grade and restock an A-grade item, the better your chances of recovering its full value. These targeted measures can help you rein in costs and improve overall efficiency.

Slow Processing and Delayed Refunds

Handling returns is a time-consuming process - processing just one return can take two to three times longer than shipping out an order. Unlike outbound shipping, which typically involves straightforward tasks like picking and packing, returns require a series of manual steps: unboxing, verifying the item, and grading it (A, B, or C). Each step demands attention, doubling the time it takes to complete.

The problem only gets worse during peak seasons. Between Thanksgiving and the end of January, return volumes can spike by as much as 60%. Facilities without dedicated staff or flexible labor to handle the influx often struggle to keep up. Without designated buffer zones - or "quarantine" areas - for these high-volume periods, unprocessed returns can clog up receiving docks, creating bottlenecks that disrupt regular operations.

Errors in system integrations add another layer of delay. Issues like data mismatches or manual entry mistakes can stall orders and refunds, requiring time-consuming manual reviews. These delays leave customers waiting longer for their money, which can hurt your reputation.

How Delays Affect Your Business

These delays don’t just inconvenience customers - they can seriously impact your business. Slow processing erodes trust. For instance, 78% of consumers have rated their most recent return experience as inconvenient, often citing slow processing as the reason. On the other hand, 96% of shoppers who find returns "easy" or "very easy" say they’re likely to shop with that retailer again. When refunds take 10 days or more to process, customers lose confidence in your brand and may not return for future purchases.

The financial costs are just as concerning. Items sitting unprocessed for two weeks can’t be resold, tying up valuable capital. For seasonal merchandise, delays can mean missing the window to sell at full price, leading to markdowns. On average, retailers see $165 million in returns for every $1 billion in sales. These numbers highlight how delays can directly affect both revenue and cash flow.

Ways to Speed Up Processing

One of the fastest ways to cut down on delays is by using RMA (Return Merchandise Authorization) barcodes on return labels. These barcodes allow warehouse staff to instantly access order details and required actions - whether it’s a refund or an exchange - reducing processing errors by as much as 80%. This automation eliminates the need for manual data entry, speeding up the entire workflow.

Another effective strategy is setting clear Service Level Agreements (SLAs) with your 3PL partner. For example, you can require returns to be processed within 48 to 72 hours of receipt, even during peak seasons. Advanced returns management systems can further streamline the process, cutting processing times by 40% to 50% and reducing labor costs by 25% to 30% compared to manual methods. Real-time API integrations between your e-commerce platform (like Shopify) and your 3PL's warehouse management system (WMS) can also automate refund notifications as soon as an item is graded, eliminating manual steps.

For busy periods, consider working with 3PLs that set up dedicated receiving lanes specifically for returns. Keeping returns separate from regular inventory shipments prevents backlogs at the docks. Prioritizing high-value items during these times can also help recover capital faster, ensuring your most profitable products are back on the shelves quickly.

Poor Inventory Visibility and Tracking

If your 3PL doesn’t provide real-time tracking, you’re essentially flying blind when it comes to returned items. Products start to pile up in warehouses, causing operational delays. Items get misplaced, inventory counts become unreliable, and you lose the chance to quickly resell - or sometimes even resell at all.

The main culprit? Data silos. Many 3PLs rely on Warehouse Management Systems (WMS) that don’t integrate well with e-commerce platforms. As one product manager at a 3PL put it, “Our WMS isn’t designed for returns - it treats them as manufacturing inbound, disrupting proper workflow”. When systems can’t communicate, inventory records fall behind reality. This disconnect can lead to overselling items still in processing or missing out on sales because your system shows zero stock, even though perfectly good returns are sitting in the warehouse. The lack of integration between systems is a major factor behind these tracking failures.

Problems Caused by Weak Tracking

Poor tracking doesn’t just add to delays - it amplifies costs and logistical headaches. Consider this: about 30% of online orders are returned, compared to just 8.9% for in-store purchases. That equates to $106 million in merchandise returns for every $1 billion in sales. When returns aren’t tracked properly, the financial impact is staggering. Unprocessed items can’t be sold, and seasonal products lose value the longer they sit idle.

Chuck Fuerst, Director of Product Marketing at ReverseLogix, sums it up well:

"With little or no visibility over all of the returns activity, 3PLs never really know where an order is in the pipeline, when it will arrive at the facility, or what to do with it once it gets there".

This lack of visibility makes it nearly impossible to plan labor effectively. Without accurate forecasts, your 3PL might not have enough staff during peak periods or could mismanage warehouse space. Manual processes only make things worse, leading to errors in grading and mishandling returned goods.

The solution? Modern tracking technologies that bridge these visibility gaps.

Better Tracking Through Technology

Trackable return labels can notify your warehouse as soon as a carrier scans a package. This early alert allows your 3PL to prepare for docking and staffing needs before the item even arrives. When paired with automated RMA systems, these labels connect returns to their original orders instantly, eliminating manual data entry errors.

Mobile scanning and barcode technology offer unit-level tracking throughout the returns journey. This method improves inventory accuracy to 99% and can cut labor costs by 25% to 30%. For example, American Eagle Outfitters eliminated return backlogs entirely by using Optoro’s returns management solution. This system leverages real-time data to route returns to their most profitable outcome - whether that’s restocking, resale, or recycling.

Performance dashboards also play a critical role. They hold your 3PL accountable by monitoring processing speed, accuracy, and inventory reconciliation. Forthmatch, for instance, tracks SLA compliance in real time, catching delays before they escalate into customer complaints or lost revenue. Its platform uses historical data to identify trends and fix problems early. With direct API integrations between Shopify and your 3PL’s systems, inventory updates happen automatically as soon as items are graded and processed.

sbb-itb-eb0f906

Inconsistent Quality Control and Grading

When your 3PL's warehouse is flooded with returns, especially during high-volume periods, inspectors often rush through the grading process. Decisions about whether an item is "new", "refurbished", or "damaged" are made quickly, often without clear and consistent guidelines. This lack of standardization can result in serious mistakes - like restocking items with missing parts, color mismatches, or structural damage such as cracks. These errors don't just affect inventory accuracy; they can also hurt your business's profitability.

Common Quality Control Issues

Returns management is a major headache for nearly 47% of warehouse operators. During peak seasons, the pressure to process returns quickly can lead to misclassifications, with defective products being labeled as "new" and returned to inventory. When customers receive these mislabeled items, complaints pile up, and your brand's reputation takes a hit. Without standardized practices, your 3PL might also mishandle sensitive items - like hazardous materials, non-working electronics, or perishables - creating potential safety and compliance risks.

"Without these checks, a brand risks reputation damage and further costly customer service interactions".

Clearly, addressing these grading inconsistencies is essential to protecting both your operations and your brand image.

Enhancing Quality Control Processes

Implementing standardized inspection protocols can take the guesswork out of grading. Digital checklists integrated into your 3PL's system ensure that every item is assessed using the same criteria, no matter the circumstances.

"Standardized inspection procedures help determine whether items can be restocked, need refurbishment, or should be disposed of".

Technology can make a big difference here. Mobile barcode scanners allow staff to verify SKU data and log item conditions in real time. This reduces manual errors, increases inventory accuracy to 99%, and cuts labor costs by 25% to 30%.

Regular quality audits are another key step. By using analytics to identify SKUs with frequent grading issues, you can address problems before they escalate. Providing your 3PL with detailed training materials and visual guides tailored to your products ensures they know exactly what "acceptable condition" means for your brand. This clarity speeds up restocking decisions and reduces errors.

Tools like Forthmatch's performance dashboards also help you stay on top of quality metrics. These dashboards flag grading inconsistencies early, so you can address them before they impact your customers' experience.

How to Choose and Improve Your 3PL Partner

What to Look for in a 3PL

Choosing the right third-party logistics (3PL) partner for handling returns goes beyond basic warehousing capabilities. One of the most important factors is ensuring they use a dedicated Returns Management System (RMS) instead of a general Warehouse Management System (WMS). Why? An RMS is specifically designed to manage the entire lifecycle of a return - from the initial authorization to the final resolution. Additionally, their system should integrate seamlessly with Shopify, allowing for real-time data updates and automated inventory adjustments.

Another key aspect to evaluate is the consistency of their inspection processes. A reliable 3PL will have standardized protocols for inspecting returned items to determine whether they can be restocked, refurbished, or discarded. Beyond inspections, look for value-added services such as refurbishment, professional repackaging, and management of secondary markets. These services ensure you can recover some value from returned products instead of treating them as total losses.

Performance guarantees are equally important. Seek out partners who back their services with measurable targets, like 100% accuracy and 0% shrinkage, to minimize the risks associated with reverse logistics. Ask for specific metrics such as returns processing times, accuracy rates, and cost per return. Confirm that they use automated Return Merchandise Authorization (RMA) systems that generate unique tracking numbers and shipping labels. Additionally, ensure they support popular Shopify returns apps like Loop, Happy Returns, or AfterShip to simplify the returns process for your customers.

Using Forthmatch to Monitor 3PL Performance

Once you've chosen a 3PL partner, keeping tabs on their performance is crucial. This is where Forthmatch comes in. It integrates directly with your Shopify store, giving you real-time insights into whether your 3PL is meeting agreed-upon Service Level Agreements (SLAs) - such as processing returns within 24 to 48 hours. Forthmatch lets you track SLA compliance, monitor return stages, check inventory status, and even see when refunds are triggered.

With features like performance dashboards and the Accountability Session, Forthmatch helps establish a performance baseline over a short 2–4 week period. The tool generates detailed PDF reports comparing metrics before and after the assessment. You can track vital statistics like return-to-stock rates, inspection accuracy, and processing times. These insights are invaluable during contract negotiations or when addressing quality control concerns.

If your current 3PL isn't delivering, Forthmatch also offers RFP tools (Request for Proposal) to help you evaluate other providers. Using your actual order data, you can create automated quote requests and compare potential partners based on standardized performance metrics. This approach ensures you're making decisions based on hard data rather than sales pitches. Selecting the right 3PL and actively monitoring their performance can make a huge difference in streamlining your returns process while keeping costs under control.

Conclusion

Handling returns doesn’t have to eat into your profits or frustrate your customers. The main obstacles - high reverse logistics costs, slow processing times, poor inventory visibility, and inconsistent quality control - all boil down to one critical issue: a lack of real-time data. Without insight into what’s happening in your 3PL’s warehouse, you’re essentially operating in the dark.

The financial impact of inefficient returns processing is hard to ignore. Each return can cost 20% to 39% of the item’s original value, and inventory errors might set you back anywhere from $10 to $250 per item. Worse yet, a bad return experience can drive away 67% of customers, while 39% won’t give your business a second chance after a poor delivery or return experience. These issues don’t just hurt your bottom line - they erode customer trust and loyalty. That’s why fast, accurate returns processing powered by real-time data is essential.

The solution is straightforward: partner with a 3PL that uses a dedicated Returns Management System (RMS), set clear SLAs with measurable goals, and actively track their performance. Automation can make a huge difference here, cutting labor costs by 25-30% and speeding up processing times by 40-50%. This combination of efficiency and accountability is key to keeping costs low and customers happy.

This is where Forthmatch steps in. The platform gives you real-time visibility into your returns process, ensuring your 3PL meets agreed-upon deadlines. It flags SLA violations instantly and provides detailed, data-driven reports to hold your partners accountable. And if your current 3PL isn’t delivering, Forthmatch’s RFP tools let you compare alternatives using actual order data, making it easier to find a better fit.

Returns management may not be the most glamorous part of e-commerce, but it’s critical to your success. With the right systems, partners, and monitoring tools, you can transform returns from a costly headache into a strategic advantage that safeguards your margins and strengthens your brand reputation.

FAQs

How does automation help lower the costs of managing product returns?

Automation has the power to drastically reduce the costs tied to handling returns by simplifying critical processes. It can handle tasks like generating shipping labels automatically, providing real-time tracking for returned items, and speeding up the approval or rejection of return requests. This approach cuts down on manual effort, lowers the chance of errors, and accelerates refunds, making the entire workflow more efficient.

By streamlining these processes, businesses not only save time and improve accuracy but also deliver a smoother experience for customers - all while keeping operational costs in check.

What are the common reasons for delays in handling returns with 3PLs?

Delays in handling returns often stem from poor visibility into the status of returned items, making it difficult to track and prioritize them efficiently. Many third-party logistics providers (3PLs) use general-purpose warehouse management systems (WMS) instead of tools designed specifically for returns, which can lead to operational hiccups.

On top of that, manual inspection processes can become a major bottleneck - especially during sudden surges in return volume, like those seen after big sales events or holidays. These issues can strain 3PL operations, slowing down the process for e-commerce brands and their customers.

Why is real-time tracking important for managing returns efficiently?

Real-time tracking provides complete transparency into the status and location of returns. For 3PLs, this means smarter resource allocation - like optimizing labor and dock space - while keeping disruptions to a minimum. On the customer side, it ensures they stay informed, helps speed up refund processing, and cuts down on the number of support inquiries.

By simplifying these workflows, real-time tracking doesn’t just boost operational efficiency; it also elevates the customer experience, fostering trust and loyalty in your brand.