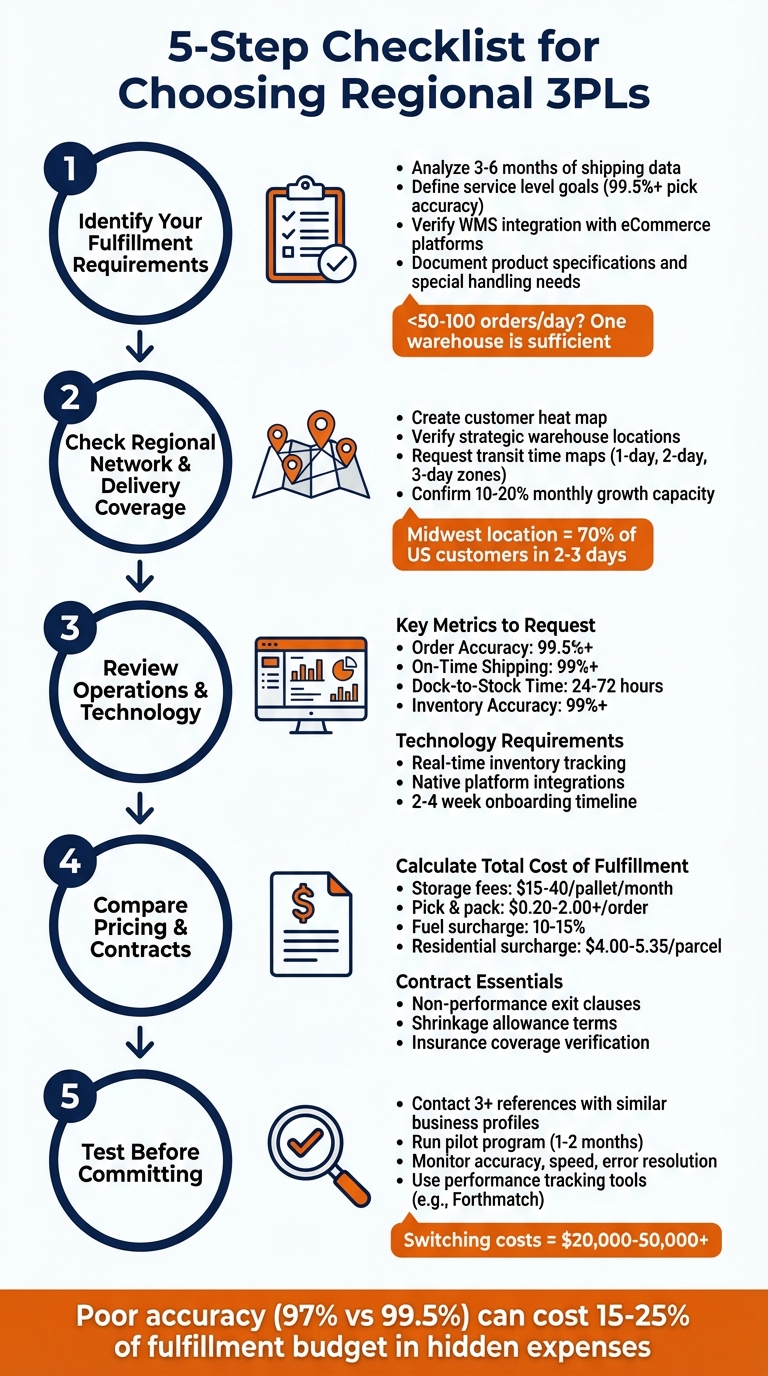

Choosing the right regional 3PL (third-party logistics provider) can directly impact your shipping speed, fulfillment costs, and customer satisfaction. The wrong choice could lead to hidden fees, delays, and unhappy customers. This guide provides a step-by-step checklist to help you evaluate potential 3PL partners and avoid costly mistakes.

Key Takeaways:

-

Understand Your Needs:

- Analyze 3–6 months of shipping data (order volumes, ZIP codes, product specs).

- Define service level goals (e.g., 99.5% pick accuracy, 2–3 day delivery).

- Ensure their WMS integrates with your eCommerce platform (Shopify, WooCommerce, etc.).

-

Evaluate Coverage & Scalability:

- Use a heat map to identify optimal warehouse locations.

- Verify their ability to handle peak growth (10–20% monthly during holidays).

- Check past performance data for Black Friday and Cyber Monday.

-

Review Operations & Technology:

- Request recent performance metrics (order accuracy, dock-to-stock times).

- Ensure real-time inventory tracking and multi-channel fulfillment capabilities.

- Test their reporting tools and onboarding timeline (2–4 weeks is ideal).

-

Assess Pricing & Contracts:

- Calculate the Total Cost of Fulfillment (TCF), including storage, pick/pack fees, and shipping surcharges.

- Review shrinkage allowances and contract terms for non-performance exit clauses.

- Confirm insurance coverage and compliance certifications for specialized products.

-

Test Before Committing:

- Contact references and run a pilot program to monitor accuracy, speed, and error resolution.

- Use tools like Forthmatch to track performance and ensure SLA compliance.

Bottom Line: A good 3PL partner aligns with your business needs, scales with your growth, and delivers consistent performance. Use this checklist to make an informed decision and protect your brand's reputation.

5-Step Checklist for Choosing the Right Regional 3PL Provider

How To Choose The Right 3PL For Your eCommerce Business

1. Identify Your Fulfillment Requirements

Before reaching out to third-party logistics providers (3PLs), take the time to outline every detail that impacts how your products move. Start by gathering 3–6 months of shipping data - this includes order volumes, customer ZIP codes, product dimensions, weights, and inventory turnover rates.

Your product's unique needs play a huge role here. A 3PL that excels in shipping apparel might not have the right setup for heavy gym equipment or temperature-sensitive cosmetics. As Portless explains:

Your category dictates your handling requirements. Fragile goods, cosmetics, batteries, oversized products, and temperature sensitive items each require different workflows.

Before you start conversations, set clear service level goals. Define what success looks like for your business: accuracy in picking and packing (top operators hit 99.5%+), cut-off times for orders, dock-to-stock speed (usually 24–72 hours), and standards for processing returns. These benchmarks will serve as your evaluation criteria.

Also, don't overlook technology. Your 3PL’s Warehouse Management System (WMS) must integrate smoothly with your eCommerce platform, whether that’s Shopify, WooCommerce, or another system. Real-time inventory tracking is non-negotiable - it’s the key to avoiding stockouts and overselling.

1.1 Analyze Your Order Volume and Customer Locations

Your order volume is a key factor in deciding whether you need one warehouse or multiple locations. If you're shipping fewer than 50–100 orders a day or generating under $5 million in gross merchandise value (GMV), one strategically located warehouse is usually sufficient.

Rich Patterson, Former Enterprise Sales Director at ShipBob, explains:

If you're not producing close to 5 million in GMV, or only ship 50-100 orders per day, you don't need multiple locations.

Keep in mind that managing multiple warehouses requires about 30% more inventory to maintain consistent stock levels. This is a major investment, so it only makes sense if the savings on shipping costs outweigh the extra expense.

Create a heat map of your U.S. order distribution to pinpoint where your customers are actually located. A well-placed facility in the Midwest can provide 2–3 day ground shipping to over 70% of U.S. customers. However, if your orders are concentrated on the coasts, you might be better off with an East/West split.

Think ahead to future growth. Can the 3PL handle 10–20% monthly growth during peak seasons? Steve Rajeckas, Content Marketing Manager at Red Stag Fulfillment, warns:

A 3PL that handles normal volume but melts down during Black Friday/Cyber Monday will cost you the sales that matter most.

Ask potential 3PLs for data on their shipping times and error rates during the last 2–3 holiday seasons. This will help you gauge whether they can scale when it matters most.

| Metric to Analyze | Why It Matters for 3PL Selection |

|---|---|

| Daily Order Volume | Determines if you need a single hub or a multi-node network. |

| Customer Heat Map | Helps identify the best location to minimize shipping zones. |

| Peak Surge Ratio | Ensures the 3PL can manage spikes during peak seasons. |

| Average Order Value | Determines if premium shipping costs align with your margins. |

| SKU Count/Turnover | Impacts storage fees and picking efficiency. |

1.2 Document Product Specifications

Make a detailed list of every SKU, including dimensions, weight, and any special handling needs. This step is critical to avoid mismatches with generalist 3PLs.

If you ship oversized or heavy items like furniture or gym equipment, confirm the 3PL has equipment for "non-conveyable" freight. Standard conveyor systems won’t cut it, and you could face unexpected surcharges or product damage without the right setup.

For fragile, high-value, or regulated products, you’ll need more than basic warehousing. Request visual proof - photos or videos - of how they handle similar items. If you’re dealing with hazmat materials, food, or medical products, make sure the 3PL can provide documentation of FDA or OSHA compliance.

Don’t forget about any value-added services your business needs, such as subscription box kitting, custom engraving, or branded packaging inserts. Specify these requirements upfront to confirm the 3PL can accommodate them.

1.3 Set Service Level Goals

Establish your performance expectations before evaluating potential partners. This creates accountability and gives you a clear way to compare providers.

Your Service Level Agreement (SLA) should cover key metrics like pick accuracy (aim for at least 99%), on-time shipping rates, dock-to-stock time (how quickly inbound inventory is ready for sale), and return processing speed. These factors directly affect customer satisfaction and your bottom line.

Determine what "fast shipping" means for your brand. Competing with Amazon? Your customers likely expect 2–3 day delivery as the norm. Check the 3PL’s daily order cut-off times to make sure they align with your shipping promises. For instance, a 2 PM cut-off might work fine, but a 10 AM cut-off could cause operational challenges.

Test their communication channels during the evaluation process. Quick response times - both during and outside business hours - are essential. A dedicated account manager is almost always better than a generic ticketing system.

Abby Nawrocki, Director of B2B Fulfillment Operations at Flexport, puts it this way:

Selecting a 3PL may seem like a daunting task, but it should be a celebration of the growth and success of your business. If you prioritize your needs such as cost, quality, and speed, you're sure to select a long-term partner that operates as a strong extension of your brand.

1.4 List Technology and Platform Requirements

Clearly outline your system and integration needs. Start by verifying platform compatibility - whether you're using Shopify, WooCommerce, BigCommerce, or another eCommerce platform.

Real-time inventory syncing is a must. You need instant visibility across all channels to avoid overselling or running out of stock. Test this functionality early in the evaluation process, not after signing a contract.

Define your reporting needs as well. Look for 3PLs that provide real-time dashboards showing order status, inventory levels, and shipping performance. Manual reports that take 24–48 hours to generate simply won’t work for today’s fast-paced direct-to-consumer operations.

If you sell across multiple channels (your website, Amazon, retail partners), confirm the 3PL can handle multi-channel fulfillment with proper inventory allocation. The system should automatically route orders to the right warehouse and carrier based on your rules.

Finally, ask about the onboarding timeline. Modern 3PLs should be able to get you up and running in 2–4 weeks. If a provider quotes 8+ weeks, consider it a warning sign.

2. Check Regional Network and Delivery Coverage

When evaluating a 3PL, make sure their warehouse locations align with your customer base. It's not just about the number of warehouses - they need to be strategically placed to deliver on time without eating into your margins.

Ask for a detailed transit time map for each warehouse. This map should clearly show 1-day, 2-day, and 3-day ground delivery zones overlaid with your customer heat map. A well-positioned warehouse can reach up to 70% of U.S. customers within 2–3 days, but only if it’s in the right spot relative to your order volume.

Also, consider proximity to ports. This can reduce drayage costs and improve inbound shipping times. As Portless explains:

Where a 3PL operates relative to your production determines your lead time, cash conversion cycle, and delivery experience.

For example, in December 2025, Maxwood Furniture partnered with Barrett Distribution Centers to expand its Western U.S. direct-to-consumer operations. They selected Barrett’s Montebello, California facility for West Coast fulfillment and planned to add a Dallas, Texas location to support further growth. Heidi Germann, Senior Manager of Operations at Maxwood, emphasized that system visibility and the geographic footprint were key factors in their decision.

Once you’ve outlined your fulfillment needs, assess whether the 3PL’s network can match your delivery and operational requirements.

2.1 Verify Warehouse Locations

Check if the 3PL operates in major logistics hubs like Boston, Los Angeles, Memphis, Dallas, or Indianapolis - cities known for their strong transportation infrastructure and dense carrier networks. However, don’t assume more locations automatically mean better service.

Sometimes, a single, well-placed warehouse can outperform a scattered network. Managing multiple warehouses often requires about 30% more inventory to maintain adequate stock levels across locations. This additional inventory is a major cash investment that only makes sense if the savings in shipping costs outweigh the expense. Carefully calculate this before committing to a multi-warehouse strategy.

If your customers are concentrated - say, 60% on the East Coast and 30% on the West Coast - splitting between two regions might make sense. But if orders are spread more evenly, a centrally located Midwest facility often provides the best balance of coverage and simplicity.

Ask about zone skipping options, too. Some 3PLs can inject packages directly into the carrier zone closest to your customer, cutting both transit time and costs compared to shipping across multiple zones. This can be a cost-effective alternative to managing your own multi-warehouse network.

2.2 Review Delivery Performance

Even the best warehouse locations mean little without strong delivery performance. Request on-time delivery rates for the past 90 days, broken down by region and carrier. Top-tier 3PLs should maintain 99%+ on-time shipping.

Also, ask for performance data from the last two or three holiday seasons, including Black Friday and Cyber Monday in 2024 and 2025. Look for any patterns of delays or errors during peak periods. If a 3PL can’t provide this data or offers vague answers, that’s a red flag. Steve Rajeckas, Content Marketing Manager at Red Stag Fulfillment, puts it bluntly:

A 3PL that handles normal volume but melts down during Black Friday/Cyber Monday will cost you the sales that matter most.

Confirm the daily order cut-off time for same-day shipping at each warehouse. A 2 PM cut-off gives you flexibility, while a 10 AM cut-off could cause headaches, especially if you run flash sales or manage orders across time zones.

Check if the 3PL offers weekend operations and same-day or next-day shipping options in your key markets. These services are increasingly expected by customers accustomed to Amazon’s fast delivery standards. FIDELITONE highlights this clearly:

The option to ship close to your target market can have a massive impact on shipping costs, as well as speed to the customer.

Finally, ensure the 3PL maintains carrier redundancy. Relying on a single carrier is risky during service disruptions, severe weather, or peak season demand surges. Ask which carriers they work with in each region and how they manage delays from their primary carrier.

2.3 Test Capacity for Growth

Your 3PL should be able to scale with your business. Confirm they can handle 10–20% month-over-month growth without compromising accuracy or service levels.

Scalability isn’t just about having extra warehouse space. The 3PL also needs sufficient labor, advanced Warehouse Management Systems (WMS), and efficient processes for onboarding new inventory. Ask about their dock-to-stock time - how long it takes to move inbound shipments from "received" to "available for sale." Top operators can do this in 24–72 hours.

If you're planning regional expansion, discuss how the 3PL would support adding new warehouse locations. For instance, in the Maxwood Furniture example, Barrett Distribution Centers began with one California facility and had a phased plan to expand as order volumes grew. This allowed Maxwood to test the partnership before committing to a full multi-warehouse strategy.

Ensure their systems can automatically route orders to the optimal warehouse based on customer location, inventory levels, and carrier performance. Manual intervention for every order should not be necessary.

Tony Runyan, Chief Client Officer at Red Stag Fulfillment, warns against focusing solely on price:

The most common mistake I see in the 3PL selection process is focusing too heavily on quoted rates... only to discover their new 3PL can't properly handle their products or scale with their growth.

Ask for case studies that demonstrate how the 3PL has supported sustained growth over 12+ months without service issues. Don't settle for vague assurances - look for real-world examples of success.

Once you’ve evaluated these factors, you can move on to reviewing the 3PL’s operational systems and technology integration.

3. Review Operations, Technology, and Performance Data

Once you've confirmed that the 3PL's network aligns with your customer base, it’s time to dig deeper into their daily operations and technology systems. This step ensures their performance meets your expectations. Evaluating key fulfillment metrics will help you validate their operational claims.

3.1 Check Core Fulfillment Metrics

Request performance data from the past 30–90 days instead of relying on annual averages. Why? Recent data reflects their current performance, not a snapshot from a slower or busier period months ago.

Here are some key metrics to focus on:

| Metric | Target Benchmark | Why It Matters |

|---|---|---|

| Order Accuracy | 99.5% or higher | Reduces returns and customer dissatisfaction. |

| Inventory Accuracy | 99%+ | Prevents stockouts and overselling. |

| Dock-to-Stock | 24–72 hours | Ensures new inventory is ready to sell quickly. |

| On-Time Shipping | 99%+ | Keeps delivery promises to customers. |

| Error Resolution | 24–48 hours | Minimizes brand damage after mistakes. |

Steve Rajeckas, Content Marketing Manager at Red Stag Fulfillment, highlights the importance of accuracy:

A 3PL quoting $0.50/pick cheaper but running 97% accuracy instead of 99.5% costs more per order.

Why? Poor accuracy leads to more customer service calls, refunds, and replacement shipments. These issues can eat up 15–25% of your fulfillment budget in hidden costs.

Another factor to consider is staff turnover rates. The warehouse industry has an annual turnover average of 49%. High turnover can directly impact accuracy and speed. A 3PL with a stable, experienced team will consistently deliver better results compared to one with frequent staffing changes.

3.2 Identify Available Add-On Services

Ensure the 3PL offers the add-on services your business needs, such as kitting, custom packaging, light assembly, or returns processing. These services can help streamline your operations and improve cost efficiency.

For instance, 73% of shippers reported that working with a 3PL improved their customer experience, while 86% said it reduced costs. However, these benefits only come if the 3PL can handle your specific product needs.

- Selling apparel? Ask about branded packaging, custom inserts, or gift wrapping.

- Selling electronics or batteries? Verify they have certifications for handling hazardous materials.

- Selling heavy items over 80 lbs? Confirm they have the equipment and manpower for oversized shipments.

Request photos or videos of how they handle similar products. This provides tangible proof of their capabilities instead of relying on verbal assurances.

Once you’ve confirmed their add-on services, take a closer look at their technology systems.

3.3 Test Technology and Reporting Tools

Ask for a live demo of their client portal and Warehouse Management System (WMS). This will give you a firsthand look at how their systems work.

Make sure their technology includes native integrations with platforms like Shopify, WooCommerce, or Amazon. If they rely on manual CSV uploads or frequent data exports, that’s a red flag. Automation is key - orders, inventory, and tracking numbers should sync seamlessly.

Sarah K, Founder of Bare Nut Butter, underscores the importance of accurate reporting:

Ask in advance for examples of inventory reporting and specific reports. If it's not accurate, then it's not really worth anything.

Also, confirm the onboarding timeline. A standard tech integration should take 2–4 weeks. If they quote 8 weeks or more, their systems may be outdated or overly complicated.

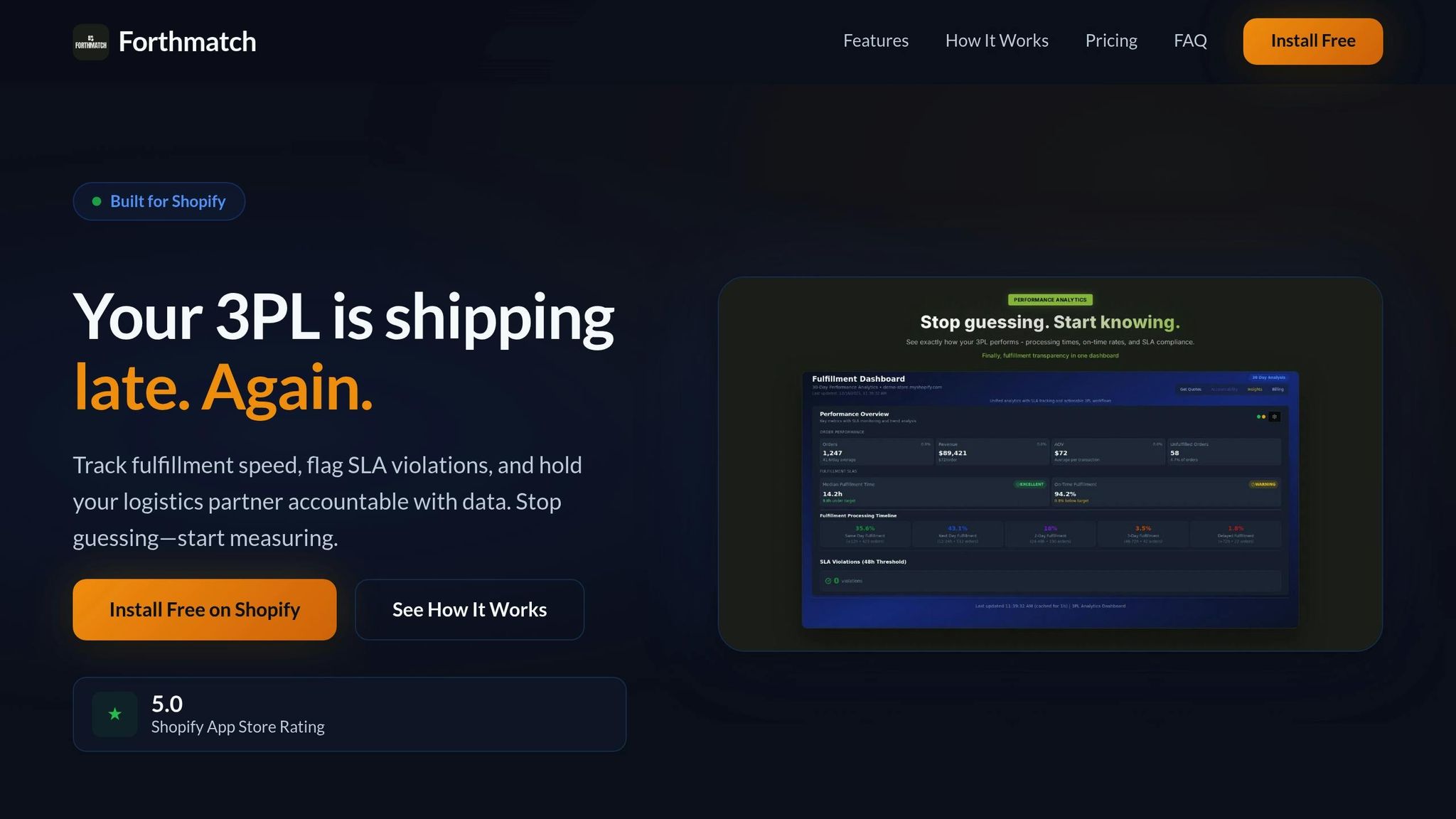

3.4 Track Performance with Forthmatch

To maintain accountability, use Forthmatch to continuously monitor your 3PL’s performance. This platform tracks shipping times, flags SLA violations, and provides analytics to pinpoint delays.

You can set specific SLA goals, like “ship within 24 hours,” and Forthmatch will notify you if the 3PL misses the mark. These insights can help you during contract negotiations and performance reviews.

Forthmatch’s tools give you the data you need to hold your 3PL accountable before their performance impacts your reputation. It’s a proactive way to ensure your operations stay on track.

sbb-itb-eb0f906

4. Compare Pricing, Contracts, and Risk Policies

Once you've assessed performance metrics, it's time to dive into the financial and contractual details. This step is all about protecting your business from hidden costs and ensuring you can walk away if the partnership doesn't meet expectations.

4.1 Request Detailed Pricing

Ask for a clear, itemized fee breakdown. Why? Because fulfillment fees make up 25–35% of each order. To make accurate comparisons, calculate the total cost of fulfillment for each 3PL.

Tony Runyan, Chief Client Officer at Red Stag Fulfillment, puts it simply:

The only way you can really get to an apples-to-apples 3PL price comparison is to calculate the total cost of fulfillment.

Here’s a snapshot of typical 2025 pricing in USD:

| Fee Category | Typical Range |

|---|---|

| Account Setup | $250–$1,000+ (one-time) |

| Inbound Receiving | $5–$15 per pallet |

| Storage (Pallet) | $15–$40 per month |

| Storage (Cubic Foot) | ~$0.46 per cubic foot |

| Pick & Pack (Base) | $0.20–$2.00+ per order |

| Fuel Surcharge | 10–15% of label cost |

| Residential Surcharge | $4.00–$5.35 per parcel |

| Address Correction | $14–$19 per parcel |

If your products are only partially palletized, cubic-foot pricing could save you ~40% compared to flat pallet rates.

Pay close attention to shipping surcharges, which can add up fast. Fuel surcharges range from 10–15% per label, while residential delivery fees add $4.00–$5.35 per package. And during Q4’s peak season, expect an extra $1.60–$3.50 per package.

Another key point: clarify the shrinkage allowance. This is the inventory loss percentage the 3PL won’t reimburse. For instance, a 2% allowance on $500,000 worth of inventory means you could lose $10,000 annually.

Joe Spisak, CEO and Founder of Fulfill.com, stresses transparency:

You need to understand the full pricing structure - storage, pick-and-pack fees, shipping rates, and any potential surcharges. A clear view of your total costs can help avoid surprises.

4.2 Review Contract Terms

Carefully review the fine print of your 3PL contract. Most agreements last three years or longer and often include automatic renewal clauses. These clauses typically require 60–90 days' notice to avoid being locked in for another term.

Make sure the contract includes termination clauses for non-performance. If the 3PL repeatedly misses key metrics - like order accuracy or shipping deadlines - you should have the option to exit without penalties.

Also, check for price escalators. While pricing is usually locked for the first 12 months, annual increases tied to a fixed percentage or the Consumer Price Index (CPI) are common.

Brian Barry, FCBCO, highlights the importance of a strong contract:

You only need a good contract when you need a good contract. Meaning when you need enforcing services or standards to protect your business and customers is not the time to discover that you have a worthless contract.

Don’t overlook the "Warehouseman’s Lien" clause. This allows the 3PL to hold your inventory until all outstanding invoices are paid. If a dispute arises, this clause could prevent you from switching providers.

If your business experiences seasonal volume spikes, confirm how the contract handles forecasting deviations. Some 3PLs charge premium rates or overtime fees if your actual volumes exceed forecasts by more than 10%.

4.3 Confirm Insurance and Compliance

Verify that your 3PL carries General Liability, Employee Dishonesty, and Workers' Compensation insurance. However, note that most contracts make you responsible for insuring your inventory against loss or damage.

Understand the shrinkage allowance stated in the contract. Standard agreements often include a 0.5% allowance, meaning you absorb losses within that limit, while the 3PL covers anything beyond it.

For specialized products, ensure the 3PL has appropriate certifications. For example:

- ISO 13485 for medical devices

- FDA and NABP accreditation for healthcare items

- SOC 2 compliance for data security

Jon Blair, Founder of Free to Grow CFO, warns about hidden costs:

If your 3PL doesn't live up to their promises, you have huge costs that don't show up on the shipping and fulfillment expense line of your P&L.

Lastly, review the Force Majeure clause. It should clearly define situations beyond the 3PL’s control - like natural disasters or labor strikes - and include a solid disaster recovery plan. These precautions are crucial for minimizing disruptions and maintaining smooth operations.

5. Verify 3PL Performance Through References and Testing

When choosing a third-party logistics (3PL) provider, it's not enough to trust their promises - you need proof they can deliver. Here's how to ensure they live up to their claims.

5.1 Contact References and Review Case Studies

Ask for references from businesses that closely resemble yours, especially in terms of product type and order volume. Generic references won’t tell you much about how the 3PL handles companies like yours.

When you reach out to these references, dig deeper than surface-level questions. For example, ask about order accuracy and on-time shipping rates over the past 30–90 days. Annual averages can hide recent performance issues. It’s also a good idea to ask how the 3PL handled high-demand periods, like Black Friday or Cyber Monday.

Find out if the 3PL assigns a dedicated account manager and how quickly they respond to urgent issues, especially outside regular business hours. Ask if they’ve supported significant growth - like a 2×–3× surge in order volume - without compromising service quality.

Hidden fees can be a nasty surprise, so confirm whether the reference encountered unexpected costs, such as peak surcharges or packaging fees. Additionally, ask for examples of how the 3PL resolved issues like inventory loss or shipping errors, and how quickly they acted.

Before signing anything, test the waters yourself. Call the 3PL’s customer service line and see how quickly you can reach a real person. This can give you an honest glimpse into their commitment to customer support. Completing this due diligence will prepare you for a focused pilot program.

5.2 Run a Pilot Program

Start with a small-scale test, using a limited selection of products rather than your entire catalog. Integration typically takes 1–2 months.

During the pilot, closely monitor key metrics like order fulfillment accuracy (aim for at least 99.5%), on-time shipping rates, and dock-to-stock time for inbound inventory (usually 24–72 hours). Track how quickly errors are acknowledged (same-day is ideal) and resolved (within 24–48 hours).

Test the technology integration by running a variety of orders to ensure real-time inventory updates sync properly without requiring manual fixes. Don’t forget to test the returns process to confirm the reverse logistics system works smoothly.

Keep detailed records of the pilot’s performance in a scorecard. This will help you evaluate the provider objectively. Pay attention to how they handle challenges like volume spikes or new product launches during the test. A well-documented pilot will also make it easier to transition into ongoing performance monitoring.

5.3 Monitor Long-Term Performance with Forthmatch

Even after selecting a 3PL, ongoing monitoring is crucial. Tools like Forthmatch can help you maintain oversight and ensure your provider sticks to agreed service levels.

Forthmatch automatically tracks how long it takes for orders to ship and flags any delays based on your SLA targets. For example, you can set a goal like "ship within 24 hours", and the app will alert you if your provider misses the mark. It analyzes your Shopify order history to calculate the time between order creation and fulfillment, giving you clear data on where delays occur. Plus, you can send one-click email alerts directly to your account manager, creating a documented trail of their responsiveness.

For quarterly reviews or contract renegotiations, Forthmatch’s Accountability Session feature ($89 per session) provides a detailed performance report. It monitors operations for 2–4 weeks and generates a PDF comparison to show improvements - or lack thereof - over time.

If your provider’s performance doesn’t improve, the RFP Generator ($44 per request) can help. It uses your actual order data to create a Request for Proposal, allowing you to compare rates and services from vetted regional providers. This ensures you’re not overpaying or settling for mediocre service.

Conclusion

Picking the right regional 3PL isn’t just about chasing the lowest price - it’s about choosing a partner that protects your reputation and grows alongside your business. Start by clearly outlining your fulfillment needs. Make sure warehouse locations are strategically placed near your customer base to cut down on shipping zones and transit times. Take a close look at the provider’s operations and technology to confirm they integrate smoothly with your existing systems. And don’t forget to evaluate the total cost of fulfillment - hidden fees or avoidable mistakes can chip away 15–25% of your budget.

To make an informed decision, review the provider’s recent performance data and consider running a pilot program. A poor initial choice could lead to switching 3PLs, which can rack up costs between $20,000 and $50,000+ due to transition expenses, lost inventory, and even customer churn. Taking these steps upfront helps lay the groundwork for a strong, lasting partnership.

Once you’ve selected a provider, ongoing performance checks are crucial to ensure they stick to their service level agreements. Tools like Forthmatch can simplify this process by automating the tracking of shipping speeds, flagging SLA breaches, and delivering quarterly performance reports. Their Performance Insights plan ($19/month with a 14-day free trial) offers real-time visibility into how your fulfillment is performing. For deeper accountability, the Accountability Session feature ($89 per session) provides detailed before-and-after comparisons to hold your provider to their promises.

If your provider isn’t meeting expectations, the RFP Generator ($44 per request) uses your actual order data to compare rates and services from vetted regional providers. This data-driven approach ensures you’re making the best decision for your business. A solid 3PL partnership can be a game-changer - tools like Forthmatch can help you maintain that edge.

FAQs

What should I evaluate about my order volume and customer locations when choosing a regional 3PL?

When choosing a regional 3PL, it’s crucial to evaluate your average monthly order volume (for instance, over 100 orders per month) and account for any seasonal surges or growth patterns. Think about your customer base - are they concentrated in certain areas or scattered nationwide? Partnering with a 3PL that offers regional warehouses or zone-skipping options can shorten shipping distances, cut costs, and improve delivery speed. This way, your logistics partner will better align with the demands of your business and the expectations of your customers.

How can I ensure a 3PL integrates smoothly with my eCommerce platform?

To make sure your 3PL works smoothly with your eCommerce platform, the first step is to confirm that their technology aligns with your system. Look into whether they provide API support or pre-built connectors for platforms like Shopify, BigCommerce, or Magento. It's also a good idea to ask for detailed documentation and access to a test environment so you can evaluate the integration process before it goes live.

Next, test essential data flows, including inventory updates, order tracking, and shipping confirmations, to verify that everything syncs in real time. Running a small-scale pilot with actual orders is a smart way to catch and fix any issues early. Also, ensure the 3PL offers dependable support for integration challenges and uses secure, encrypted methods to safeguard customer data.

Taking these steps will help your 3PL and eCommerce platform work together seamlessly, reducing potential errors and improving the overall customer experience.

What should I look for in a 3PL contract before signing?

When going through a 3PL contract, it’s essential to pay attention to specific terms that safeguard your business and ensure everything is clearly defined. Start with the Statement of Work (SOW) - this should detail all the services the 3PL will provide. Review the contract's duration, any auto-renewal conditions, and your rights to cancel the agreement.

Make sure pricing and payment terms are straightforward and leave no room for confusion. It's also crucial to confirm the inclusion of Service Level Agreements (SLAs), which should set measurable performance standards and outline penalties if those standards aren’t met. Don’t overlook the 3PL’s liability and insurance coverage - this is vital for protecting your inventory. Additionally, check for confidentiality and indemnification clauses to ensure your business interests are well-protected. Finally, ensure the contract includes a clear dispute-resolution process for handling conflicts quickly and effectively.