Managing multi-channel fulfillment effectively means centralizing inventory and order processing across platforms like Shopify, Amazon, and eBay. Partnering with the right third-party logistics provider (3PL) is key to handling this complexity while meeting customer expectations.

Here’s what you need to focus on:

- Assess your current fulfillment process: Identify inefficiencies like stockouts, delays, or errors.

- Set clear requirements: Define order volumes, delivery speeds, special handling needs, and costs.

- Choose the right 3PL: Look for omnichannel capabilities, proven performance, and scalability.

- Integrate technology: Sync your systems for real-time inventory updates and automated workflows.

- Establish SLAs and communication: Set measurable goals like 99.9% order accuracy and review performance regularly.

With 85% of customers unwilling to return after a poor delivery experience, aligning your 3PL with your fulfillment needs can directly impact your brand’s reputation and retention rates.

Amazon Multichannel Fulfillment (MCF) vs 3PL: Which Is Better for You | AMZ Prep

Review Your Current Fulfillment Setup

3PL Performance Metrics: Industry Standards vs World-Class Targets

Take a close look at your fulfillment process to identify where things might be going wrong. Start by gathering data from the last 30–90 days across all your sales channels - Shopify, Amazon, eBay, Walmart, and any others you use. Focus on metrics like order accuracy, shipping times, and customer complaints. This analysis will help you uncover inefficiencies and pinpoint areas where costs are unnecessarily high.

Retailers lose a staggering $634 billion annually due to out-of-stock items and another $471.9 billion because of overstocking. Without real-time inventory visibility across all your channels, you risk contributing to these costly problems. Alarmingly, 43% of small businesses in the U.S. don’t track their inventory, which often leads to overselling or phantom stock issues. Your first priority? Make sure you’re not part of that statistic.

Find Your Operational Problems

Zero in on the specific issues within your fulfillment setup. For example, every picking error costs businesses an average of $42, and 65% of consumers have returned items due to shipping damage. These mistakes aren’t just costly - they also hurt customer retention.

Use the "5 Whys" method to dig deep into the root causes of problems. If a shipment was delayed, don’t settle for blaming the carrier. Ask why the delay happened. Was the item not in stock when promised? Was there a manual error or a system sync issue? Keep asking "why" until you uncover the real problem. For instance, maybe your Shopify sales aren’t syncing with Amazon inventory in real time, or your warehouse is understaffed during key periods. A physical inventory audit can also help eliminate phantom stock issues. Cross-check your digital records with what’s actually in your warehouse or 3PL facility to ensure accuracy.

Real-time inventory updates are critical to avoid overselling. Even a slight delay can cause major headaches. On Amazon, an Order Defect Rate above 1% could lead to account suspension, while the threshold on eBay and Walmart is 2%. Additionally, track returns by specific reasons, such as "wrong item shipped", "damaged in transit", or "late delivery." This will help you separate 3PL performance issues from product-related concerns. Repeated errors tied to particular SKUs or order types might point to inefficiencies in picking or packaging processes.

"Your 3PL partnership shouldn't feel like operating in a black box."

- Steve Rajeckas, Content Marketing Manager, Red Stag Fulfillment

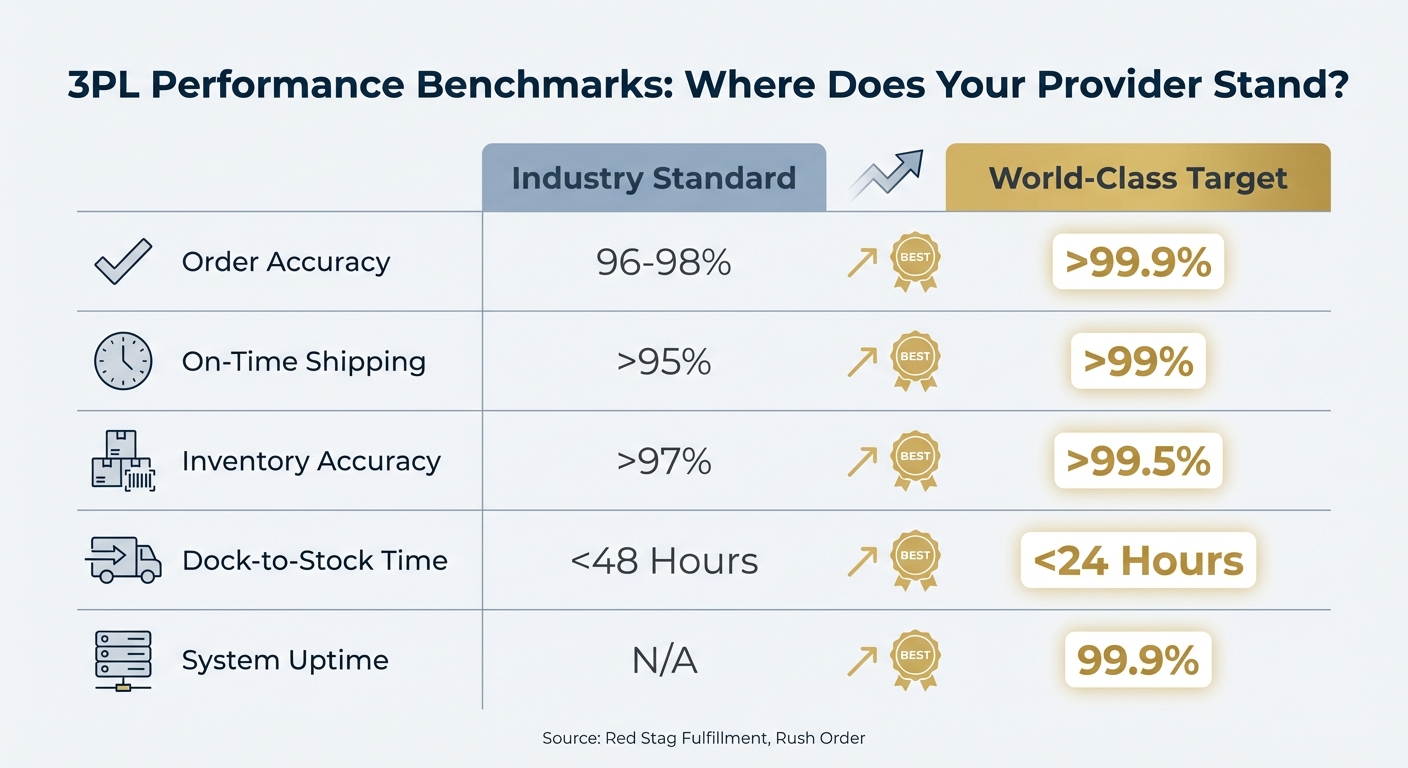

Compare your performance to industry benchmarks. Keep an eye on metrics like these:

| Metric | Industry Standard | World-Class Target |

|---|---|---|

| Order Accuracy | 96-98% | >99.9% |

| On-Time Shipping | >95% | >99% |

| Inventory Accuracy | >97% | >99.5% |

| Dock-to-Stock Time | < 48 Hours | < 24 Hours |

Source: Red Stag Fulfillment

Pay special attention to dock-to-stock time - the time it takes from when inventory arrives at your warehouse until it’s ready for sale. If this process regularly takes longer than 48 hours, you’re losing revenue even though the products are physically available. Identify these bottlenecks and note specific metrics to create a performance baseline.

Write Down Your Fulfillment Needs

Now, outline your specific requirements for each sales channel. Avoid vague goals like "faster shipping" and instead, create clear and measurable criteria to evaluate potential 3PL providers and set service level agreements.

Start by documenting your weekly, peak, and seasonal order volumes. For example, you might process 500 orders weekly, scaling up to 2,000 on peak days. Include your current SKU count and account for future growth - if you’re adding 50 new products each quarter, your warehouse management system must handle this expansion seamlessly.

Define delivery speed expectations by channel. For instance, you may need two-day shipping for Amazon Prime orders or next-day delivery for VIP customers. Wholesale or B2B orders might allow more flexible timelines but could require specific packaging or labeling to meet compliance standards. Break down transit times for each shipping zone, whether it’s the West Coast, Midwest, East Coast, or international markets.

Also, map out your shipping zones and customer concentration. If 60% of your orders are headed to California, Texas, and Florida, choose a 3PL located strategically to serve these areas. Calculate how many of your customers can be reached within one or two days from potential warehouse locations. For brands shipping fewer than 100 orders daily or generating less than $5 million in gross merchandise value, one strategically placed warehouse is often enough. However, multiple locations can add about 30% more complexity and cost.

Don’t forget to include any special handling needs. For example, you might require temperature-controlled storage for cosmetics or food items, certifications for hazardous materials, or kitting and bundling for subscription boxes. Wholesale orders might demand EDI integration or GS1-128 labels. These aren’t just extras - they’re essential for meeting your business requirements.

Lastly, calculate your total fulfillment costs, which go beyond just the quoted rates. Factor in hidden expenses like labor for fixing errors, customer service costs, lost revenue from stockouts, and the cost of replacing damaged inventory. Many brands lose 15–25% of their fulfillment budget to hidden fees, shipping mistakes, and customer service overhead. Knowing your true costs will give you a solid foundation for evaluating 3PL proposals.

Using integrated analytics and performance-monitoring tools can make this review process easier. Platforms like Forthmatch provide real-time insights into your fulfillment operations across all channels, helping you identify inefficiencies and improve continuously.

Select a 3PL That Fits Your Business

After documenting your fulfillment needs, the next step is to find a 3PL partner that can meet those requirements with proven efficiency and the ability to grow alongside your business. With around 60% of all ecommerce shipments managed by 3PL providers, the market is crowded. But not every provider is equipped to handle the complexities of multi-channel operations.

Focus your search on providers specializing in omnichannel fulfillment. Many traditional 3PLs are designed for wholesale clients, moving pallets on predictable schedules. This setup works for shipping to big-box retailers but falls short when managing direct-to-consumer orders on platforms like Shopify, maintaining Amazon FBA inventory, or ensuring compliance with retail giants like Walmart. Omnichannel fulfillment demands advanced order routing, real-time inventory tracking, and seamless integration with multiple sales channels. Once you’ve identified potential partners, evaluate their operational and technological capabilities to ensure they align with your needs.

Check 3PL Capabilities

Assess each 3PL against your documented requirements. For example, your 3PL's warehouse management system (WMS) should integrate directly with ecommerce platforms like Shopify or Magento, marketplaces such as Amazon and Walmart, and POS systems via API connectivity. This eliminates manual data entry errors and sync issues.

Location matters, too. Choose facilities near major customer hubs - like California, Texas, or Florida - to minimize shipping times and costs. For smaller brands shipping under 100 orders daily or earning less than $5 million in gross merchandise value, a single, strategically placed warehouse might suffice. However, expanding to multiple locations requires careful planning, as it can increase inventory needs by about 30%.

If you’re selling to big-box retailers, retail compliance expertise is non-negotiable. Your 3PL must handle GS1-128 labeling, Advance Shipping Notices (ASNs), and EDI transaction sets without errors to avoid costly chargebacks. Additionally, verify that they offer flexible fulfillment options like Buy Online Pick Up In-Store (BOPIS), curbside pickup, or Amazon Seller Fulfilled Prime (SFP). Don’t overlook reverse logistics - your provider should be equipped to inspect, refurbish, and restock returns seamlessly into your inventory.

Scalability is another critical factor. Ask for data showing how the 3PL performed during peak periods like Black Friday Cyber Monday (BFCM) 2025 and what improvements they made afterward. High staff turnover, which averages 49%, can lead to picking errors and delays. Inquire about their 12-month turnover rate and how they train temporary staff for surges. During site visits, observe operational culture - well-maintained employee areas often reflect broader care for operations. Ensure the facility isn’t already operating at capacity and that they can handle peak demand with surplus labor and carrier capacity. Be cautious of promises of "instant scaling", as these can indicate reliance on temporary labor or unstable processes.

Once operational capabilities are confirmed, move on to a cost comparison.

Use Data to Compare Providers

To compare providers, calculate the Total Cost of Fulfillment (TCF). This includes not just rate cards but also indirect costs like delayed shipments or increased customer service demands. Hidden fees, shipping errors, and additional overhead can eat up 15–25% of your fulfillment budget.

"The most common mistake I see in the 3PL selection process is focusing too heavily on quoted rates or the perceived benefits of a particular location."

- Tony Runyan, Chief Client Officer, Red Stag Fulfillment

Request detailed, itemized quotes based on your historical data, covering storage, order processing, receiving fees, and peak season surcharges. Also, ask for performance records from both regular operations and peak times. Providers who back their claims with Service Level Agreements (SLAs) offering penalties or credits for missed targets are worth prioritizing.

Top-performing operations usually achieve metrics like:

| Metric | Industry Standard | World-Class Target |

|---|---|---|

| Order Accuracy | 96–98% | >99.9% |

| On-Time Shipping | >95% | >99% |

| Inventory Accuracy | >97% | >99.5% |

| Dock-to-Stock Time | <48 Hours | <24 Hours |

| System Uptime | N/A | 99.9% |

Source: Red Stag Fulfillment, Rush Order

Talk to current clients of similar size and ask pointed questions: How does the 3PL handle seasonal spikes? Were there any unexpected costs? How quickly do they resolve urgent issues? Aim for a response time under 4 hours. Also, verify dock-to-stock speeds - inventory should be ready for sale in under 48 hours for standard operations and under 24 hours for top-tier providers. Delays here can directly impact revenue.

Real-world examples highlight the importance of choosing wisely. Poppi, a beverage retailer, cut its order fulfillment costs by 30% with Amazon Multi-Channel Fulfillment. VAHDAM India reduced costs by 15% while driving 400% annual sales growth, serving over 2 million customers. Likewise, Vogmask managed a 900% surge in orders during the COVID-19 pandemic by switching to an omnichannel 3PL, maintaining a 92% customer satisfaction rate.

Tools like Forthmatch can simplify the comparison process. Forthmatch’s RFP generator uses your order data to create detailed proposals and match you with vetted regional providers that fit your needs - without extra fees or middlemen.

"If your 3PL doesn't live up to their promises, you have huge costs that don't show up on the shipping and fulfillment expense line of your P&L."

- Jon Blair, Founder, Free to Grow CFO

Choose a partner that can handle your current needs and support growth of 10–20% month-over-month without compromising SLAs or service quality. The right 3PL should feel like an extension of your team, not a separate entity you simply hand orders to and hope for the best.

Connect Your Technology Systems

Once you've chosen a reliable 3PL, the next step is connecting your systems. Seamless integration between your ecommerce platform and your 3PL's warehouse management system (WMS) is essential. Without it, you're stuck with manual processes that slow down orders and increase the likelihood of mistakes. Shockingly, about 55% of companies still rely on manual "pen-and-paper" methods for managing omnichannel logistics. On top of that, 22% of online shoppers abandon their carts when delivery estimates seem too slow.

Integration acts as a digital handshake. For example, when a customer completes a purchase on Shopify, the order is instantly transmitted to the 3PL's WMS without errors. Once the package is shipped, tracking numbers sync back to your store, triggering automatic updates for customers and reducing "Where's my order?" inquiries.

"Integration is the high-speed data cable that connects the two [the store and the warehouse]. Without integration, you are the cable."

The benefits of integration are clear. Wyze, for instance, cut delivery times in half after implementing system integration. Similarly, Vogmask managed a 900% spike in order volume during the COVID-19 pandemic by using an omnichannel 3PL with integrated systems that offered real-time visibility. Companies with strong omnichannel programs also retain 89% of their customers, compared to just 33% for weaker programs.

Link Your Ecommerce Platform to Your 3PL

The first step is deciding how to integrate your systems. For most businesses, pre-built plug-and-play apps work best. These apps, often available in your ecommerce platform's app store, can fully integrate your systems in just 1–2 days. For example, the MCF App for Shopify connects Amazon's fulfillment network to your Shopify store at no cost. Dragon Glassware used the WebBee app to sync Amazon inventory with Shopify orders, enabling automated fulfillment and real-time tracking across channels.

If your website is custom-built or your business has unique needs - like handling complex product bundles or specific return workflows - you'll need a custom API integration. While this option provides maximum flexibility, it requires developer resources and typically takes several weeks to set up. For brands working with major retailers like Walmart or Target, Electronic Data Interchange (EDI) integration is often required, though it relies on older, less flexible technology.

Accurate SKU mapping is critical during setup. Each product in your store must align perfectly with its corresponding SKU and bin location in the 3PL's WMS. Use a test environment to verify that orders appear correctly, inventory levels sync with your storefront, and tracking numbers update automatically. After going live, closely monitor the integration for the first 48 hours to catch and resolve any issues, such as missed orders or inventory discrepancies.

For businesses selling on multiple channels - like Shopify, Amazon, and eBay - middleware tools like ShipStation, Veeqo, or Pipe17 can simplify operations. These platforms act as a central hub, consolidating orders from various channels and sending them to your 3PL in a unified format.

| Integration Type | Best For | Pros | Cons |

|---|---|---|---|

| Plug-and-Play Apps | Small to mid-size stores | Quick setup (1–2 days), no coding | Limited customization |

| Custom API | Large enterprises | Maximum flexibility, custom logic | Expensive, requires developers |

| EDI | B2B / Major retailers | Necessary for Walmart, Target, etc. | Rigid, outdated technology |

| File-based (CSV) | Small-scale or testing | Simple, no development required | Manual, prone to errors |

To avoid overselling, ensure your integration supports bi-directional syncing so inventory updates happen in real time. This is especially important, as 40% of global online shoppers expect their orders to arrive within 24 hours.

Use Real-Time Data and Analytics

A well-integrated system gives you real-time visibility into the entire fulfillment process. Instead of waiting for weekly reports or digging through emails to find out why an order was delayed, you can monitor everything as it happens.

Advanced integrations come with automated order routing, which directs each order to the best fulfillment center based on factors like product availability, customer location, and shipping costs. This is especially useful for businesses with multiple warehouses or those blending 3PL services with their own retail locations. Automated routing minimizes processing time by queuing orders based on carrier cut-off times, eliminating manual intervention.

But integration isn’t just about efficiency - it’s about turning raw data into actionable insights. Tools like Forthmatch are game-changers for Shopify merchants. They automatically analyze metrics like the time between "Order Created" and "Fulfillment" timestamps, providing up to 90 days of historical data immediately upon installation.

With tools like these, you can set clear SLA targets, such as shipping orders within 24 hours if placed before 2:00 PM. Forthmatch flags any violations in real time, offering concrete data like, "15% of orders missed the 24-hour SLA last week, with delays concentrated on Mondays." It also breaks down issues by carrier, product type, and day of the week, so you know exactly where improvements are needed.

This data becomes invaluable during quarterly reviews or contract negotiations. Forthmatch even offers an Accountability Session feature ($89 per session), which monitors performance over 2–4 weeks and generates a detailed PDF report comparing results before and after the session.

If your 3PL isn’t delivering, Forthmatch's RFP Generator ($44 per request) uses your order data to create detailed proposals, helping you find vetted regional providers that better suit your needs [Forthmatch].

"The technology gap between traditional and omnichannel 3PLs is substantial - omnichannel providers require sophisticated order routing logic, real-time inventory visibility across locations, and integration capabilities with dozens of sales channels."

Finally, set up automated reporting to ensure your 3PL meets key performance metrics, such as 99.9% order accuracy and same-day shipping for orders placed before cut-off times.

sbb-itb-eb0f906

Set SLAs and Communication Rules

Integrating technology might streamline order processing, but clear expectations are what truly sustain a successful partnership with your 3PL. Without well-defined service level agreements (SLAs) and regular communication, you could find yourself guessing whether your 3PL is delivering exceptional service or just scraping by. And when delivery fails, it’s your brand - not the fulfillment partner - that customers blame. Poor performance can cost you shoppers and tarnish your reputation.

An SLA turns vague promises into measurable commitments by outlining specific service definitions, performance benchmarks, reporting requirements, and even penalties or incentives for meeting - or missing - those targets. Different brands will prioritize different metrics. For instance, a luxury retailer might focus on order accuracy, while a cost-sensitive brand might emphasize keeping expenses low.

To ensure smooth operations, assign someone from your team to oversee forecasts, capacity planning, invoice checks, and performance tracking. Share detailed forecasts of order volumes and incoming inventory well in advance so your 3PL can adjust labor and storage capacity accordingly. If you’re planning major changes - like launching new sales channels, running promotions, or updating packaging - loop your 3PL in early to give them time to prepare. This proactive communication, combined with your integrated systems, helps enforce accountability.

Define Specific SLA Targets

Once communication is in place, it’s time to establish concrete performance targets. Industry standards can serve as a starting point, but aiming higher can push your operations to the next level. For example:

- Order Accuracy: Industry norms range from 96–98%, but top-tier 3PLs exceed 99.9%.

- On-Time Shipping: While 95% is standard, leading providers achieve 99% or more.

- Inventory Accuracy: Anything above 97% is acceptable, but the best operations hit 99.5%.

Another critical metric is dock-to-stock time - the period between receiving inventory and making it available for sale. While the standard is under 48 hours, top-performing 3PLs complete this in under 24 hours. These numbers matter because mistakes can be costly: a single picking error averages $42, and processing a return can cost more than $3.90.

Set clear cutoff times to manage customer expectations. For instance, orders placed before noon could ship the same day. For sellers on platforms like Amazon's Seller Fulfilled Prime or Walmart Marketplace, your 3PL’s performance directly impacts your account standing.

Your SLA structure should reflect your business model. For example:

- Customer-Based SLAs: Tailored to meet specific client needs.

- Service-Based SLAs: Standardized metrics for all clients, like a 99% order accuracy rate.

- Multi-Level SLAs: Different performance tiers, such as 1–2 days for premium shipping versus 3–5 days for standard delivery.

Don’t forget to include root cause analysis requirements. If an SLA is breached, your 3PL should investigate the issue, identify the cause, and document corrective actions. Also, set a response time for inquiries - such as replying to emails within three hours - to address exceptions quickly.

"Shipping accuracy should be a top priority for 3PLs. Everybody loses if our partners' customers don't receive orders on time and in full."

- Tony Runyan, Chief Client Officer, Red Stag Fulfillment

Establish Regular Communication

Just as integration keeps data flowing, regular communication ensures your fulfillment operations stay on track. Schedule recurring meetings to address concerns and review performance:

- Weekly Huddles: Quick 15–30 minute meetings to tackle immediate issues like volume spikes, carrier delays, or inventory shortages. These keep operations managers aligned on daily execution.

- Monthly KPI Reviews: Dive into scorecard performance to analyze which metrics were met or missed and why. Weighted scorecards can help prioritize metrics based on your business needs.

- Quarterly Strategic Reviews: Take a big-picture view of the past 90 days, plan for seasonal peaks, and address capacity needs. These meetings should include senior management from both your team and your 3PL, with action items clearly assigned and deadlines documented.

| Meeting Type | Frequency | Primary Focus | Key Participants |

|---|---|---|---|

| Ops Huddle | Weekly | Tactical issues, volume spikes, disruptions | Operations Managers |

| KPI Review | Monthly | Scorecard performance, root cause analysis | Account Managers |

| Strategic Review (QBR) | Quarterly | Capacity planning, growth goals, contract review | Senior Management |

If an SLA is missed, implement a Corrective Action Plan (CAP). This should outline the issue, its root cause, the solution, and who is responsible, along with a deadline. Use methods like the "5 Whys" to dig deep into problems. For instance, if orders are delayed due to understaffing, keep asking “why” until you uncover the root issue, such as wage competitiveness or scheduling inefficiencies.

Define escalation triggers in advance. A major SLA breach - like missing 20% of orders in a week - might warrant an emergency review, while repeated minor issues could also require escalation if they persist despite corrective actions. Always document meetings with detailed notes, assigned action items, and follow-up deadlines to maintain accountability.

"The vast majority of issues with 3PL performance can be traced back to communication breakdowns on both sides."

- Jim Sharkey, Mochila

For Shopify merchants, platforms like Forthmatch simplify SLA monitoring. The tool flags violations in real time, such as identifying when 15% of orders missed a 24-hour SLA, and tracks delays by day. It even logs alerts sent to your 3PL and their responses, creating a clear record. Forthmatch’s Accountability Session feature ($89 per session) helps track performance over 2–4 weeks, generating reports for quarterly reviews or contract adjustments. This functionality makes it easier to hold your 3PL accountable and improve operations.

Track Performance and Make Improvements

Establishing clear SLAs and communication protocols is just the beginning of a solid partnership with your 3PL. To truly succeed, you need to consistently track performance metrics. This allows you to address issues before they affect your customers. The difference between a fulfillment operation that struggles and one that thrives often comes down to how effectively you measure, analyze, and act on performance data.

Monitor Key Fulfillment Metrics

Keeping an eye on key metrics is critical to running a profitable operation. Metrics like Order Accuracy, On-Time Shipping, Inventory Accuracy, Dock-to-Stock Time, and financial indicators should always be on your radar. Here’s why these numbers matter:

- Order Accuracy: A rate above 99% is essential to retain customers. Even one fulfillment error can deter 20% of customers from reordering.

- On-Time Shipping: Aim for at least 95%, though top-tier 3PLs often hit 99% or higher.

- Inventory Accuracy: Keeping this above 99% helps prevent stockouts and overselling.

- Dock-to-Stock Time: Ideally, this should be under 48 hours, with leading operations achieving less than 24 hours.

- Financial Metrics: Key indicators include Cost Per Order (fulfillment expense divided by total orders) and Cost Per Unit Shipped, which ensure your per-unit economics stay profitable.

Another important metric is the Perfect Order Rate, which tracks orders that are complete, accurate, on time, and undamaged. This should reach 95% or higher. Additionally, Return Processing Times should be kept within 48–72 hours for 95% of returns.

Failing to track these numbers can lead to costly mistakes. For instance, some companies have reported significant annual losses due to untracked picking errors, unexpected expedited shipping costs, and shrinkage. Regularly reviewing these metrics ensures you can make adjustments to improve operations.

Conduct Regular Performance Reviews

Monthly performance reviews are essential for identifying and addressing any issues. If metrics drop, use a systematic approach like the "5 Whys" to uncover root causes - whether it’s understaffing, scheduling problems, or other operational inefficiencies. Once the issue is identified, create a Corrective Action Plan (CAP). This should outline the problem, its root cause, the solution, who is responsible, and deadlines for resolution.

For Shopify merchants, tools like Forthmatch can simplify this process. It flags SLA violations in real time, categorizes delays, and logs alerts sent to your 3PL.

"The solution isn't more frequent check-ins or heated phone calls - it's implementing a systematic approach to measuring, monitoring, and improving your 3PL's performance through data-driven accountability."

- Steve Rajeckas, Content Marketing Manager, Red Stag Fulfillment

When preparing for quarterly strategic reviews, share materials 3–5 days in advance to foster productive discussions. Use these meetings to bring in direct customer feedback about delivery experiences, emphasizing the impact of performance issues. Document all action items, responsibilities, and deadlines to ensure follow-through. Be vigilant for warning signs like unexplained inventory discrepancies, drops in accuracy during peak times, or unexpected fees.

Plan for Growth and Peak Seasons

As your business grows, your strategies must evolve. Use quarterly reviews to discuss upcoming high-demand periods, like Black Friday, and how your 3PL plans to handle the increased volume. Share detailed forecasts of order volumes and incoming inventory well in advance so your 3PL can adjust labor and storage capacity as needed. Notify them of any changes, such as new sales channels, promotions, or packaging updates.

Predictive analytics can be particularly helpful here, as they can model how future events might impact picking accuracy or processing times based on historical trends. Adjust your KPIs to reflect your current priorities. For example, a luxury brand may prioritize accuracy, while high-volume businesses might focus on speed. Instead of aiming for a fixed target, set performance bands like "Below", "Meets", or "Exceeds Expectations" for each metric.

If your 3PL consistently underperforms despite corrective measures, it might be time to explore other options. Tools like Forthmatch's RFP Generator ($44 per request) can help you create a Request for Proposal using your actual order data. This allows you to compare your current rates with those of pre-vetted regional providers.

Conclusion

Successfully aligning your 3PL with multi-channel fulfillment hinges on clear communication, integrated technology, and measurable accountability. Start by evaluating your current fulfillment setup to pinpoint operational gaps. From there, choose a 3PL partner whose capabilities align with your needs across direct-to-consumer (DTC), marketplace, and retail channels. Use tools like API or EDI integration to maintain real-time inventory visibility.

Once your fulfillment system is in place, focus on defining performance metrics. Set measurable SLAs, aiming for benchmarks like 99.9% order accuracy and 99.5% on-time shipping. Establish a structured review process that includes weekly operational updates, monthly KPI evaluations, and quarterly strategic planning sessions. This transforms vague challenges into actionable goals.

Treat your 3PL as a strategic partner to unlock efficiencies. For example, pooling inventory across channels can cut inventory levels by 15–30% and lower fulfillment costs by 20–25%. Achieving this requires leveraging technology for automated order routing, using analytics to forecast demand, and ensuring the flexibility to scale during busy seasons.

Keep in mind that 85% of consumers are unlikely to return after a poor delivery experience. Customers see no distinction between your brand and your 3PL - every late shipment or fulfillment error reflects directly on you. Continuous monitoring and improvement are non-negotiable for protecting your brand’s reputation and ensuring customer loyalty.

To consistently meet customer expectations, smart tools can make all the difference. For Shopify merchants, solutions like Forthmatch (starting at $19/month with a 14-day free trial) can automate SLA tracking, flag issues in real time, and generate data-backed reports to facilitate productive conversations with your 3PL. Whether you're scaling a startup or navigating seasonal demand surges, combining technology, clear expectations, and systematic accountability is key to sustainable growth.

FAQs

What should I consider when choosing a 3PL for multi-channel fulfillment?

Selecting the right 3PL for multi-channel fulfillment takes thoughtful consideration to ensure your operations run smoothly and your customers enjoy a consistent experience. Start by confirming the provider meets your brand's standards for shipping, packaging, and presentation. This ensures a seamless unboxing experience, no matter where your customers shop.

Costs and accuracy should be your next focus. Look beyond the obvious pick-and-pack fees - watch out for hidden costs like rework, shipping errors, or missed delivery deadlines. Sometimes, paying a little more upfront can save you money in the long run if the provider offers higher accuracy and fewer mistakes.

Take a close look at their performance metrics, too. Key indicators like order accuracy, on-time shipping rates, and how quickly they resolve errors are essential. Make sure they back these metrics with service level agreements (SLAs) that include financial accountability if they miss their targets. Also, confirm that their system integrates smoothly with your e-commerce platform, marketplaces, and order management system to keep inventory and orders in sync.

Finally, think about their scalability and reach. Can they grow alongside your business? Look for a partner that offers services like returns handling and international shipping when you need them.

Tools like Forthmatch can make this process easier. They provide real-time analytics, SLA comparisons, and automated quote requests, giving you the insights you need to make informed decisions with confidence.

How does integrating technology with your 3PL improve order accuracy and customer satisfaction?

Integrating technology brings together your storefront, order management system, and your 3PL’s warehouse management software into a unified data flow. This streamlined setup eliminates the need for manual data entry, cutting down on common errors like mismatched SKUs or incorrect item picking. The payoff? Quicker order processing, fewer mistakes, and better inventory accuracy, which helps you sidestep backorders or cancellations.

With access to real-time data, both you and your 3PL can maintain consistent standards for packaging, labeling, and delivery across all your sales channels - whether it’s Shopify, Amazon, or Walmart. Plus, you can instantly track delays or exceptions and take immediate action, like rerouting shipments, to ensure on-time delivery and keep your customers happy.

For Shopify merchants, Forthmatch makes this process even easier by directly connecting your store with 3PL systems. It provides real-time fulfillment analytics and automates essential workflows, helping you maintain accuracy and resolve service issues quickly. This ensures your customers get the right product on time, every time.

What key metrics should I track to evaluate my 3PL partner's performance?

To make sure your 3PL partner is delivering on your business needs, keep an eye on key performance metrics like these:

- Order accuracy rate: Measures the percentage of orders fulfilled without errors.

- On-time shipping rate: Tracks how often orders are shipped and delivered as promised.

- Order fulfillment speed: Looks at how quickly orders move from receipt to shipment.

- Inventory accuracy: Ensures your recorded stock levels match the actual inventory.

- Cost per order: Calculates the total expense of fulfilling each order, including shipping and handling.

- Return processing time: Monitors how fast returned products are processed and restocked.

- Customer satisfaction scores: Metrics like CSAT or NPS that reflect how happy your customers are.

By regularly reviewing these metrics, you can pinpoint areas that need attention and ensure your 3PL partner stays in sync with your fulfillment goals. For added insight, tools like Forthmatch offer real-time analytics and actionable data to help you track and refine these metrics with ease.