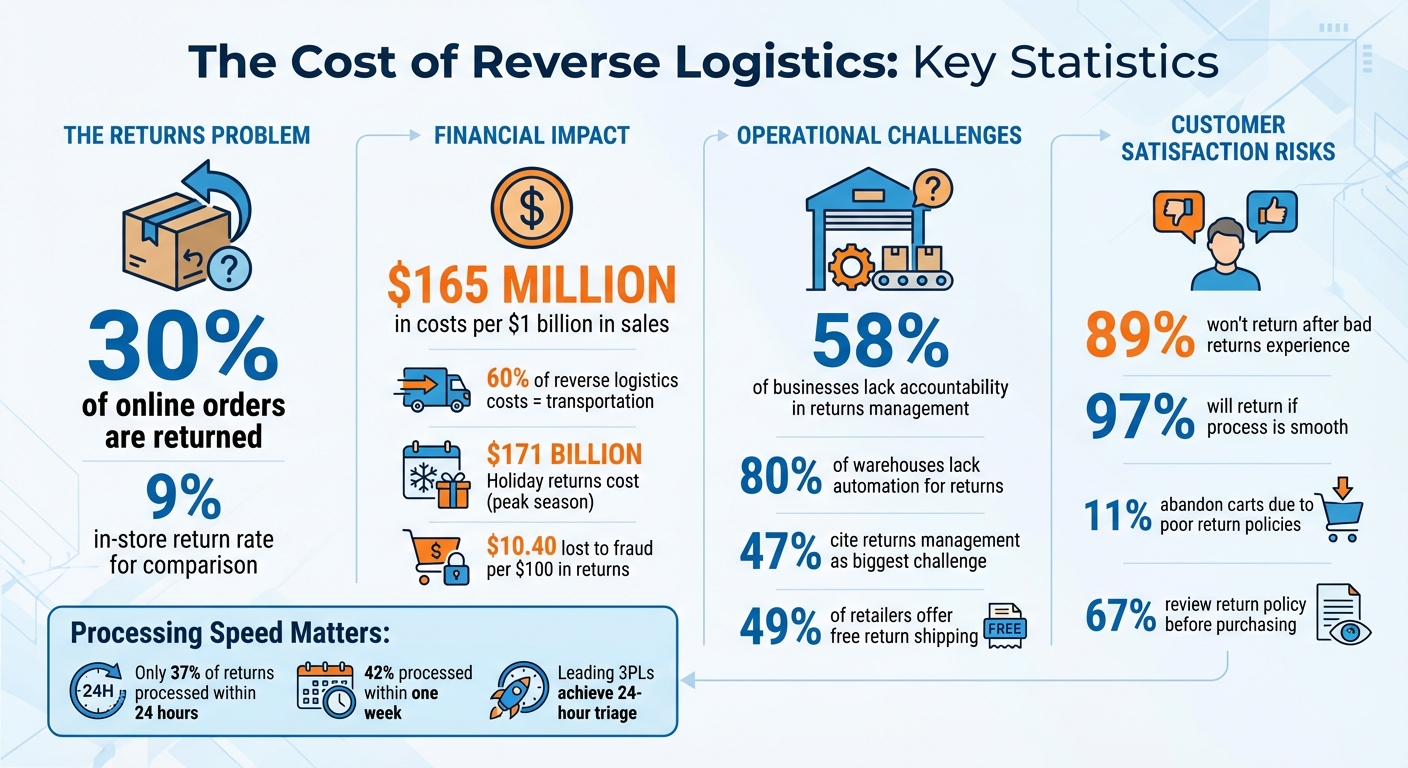

Reverse logistics, or managing product returns in e-commerce, is costly and challenging. With 30% of online orders returned (compared to 9% for in-store purchases), businesses face rising costs, operational inefficiencies, and customer dissatisfaction. Returns cost retailers $165 million per $1 billion in sales, with 60% of reverse logistics costs tied to transportation. Poorly managed returns also lead to stock errors, warehouse clutter, and lost customer trust - 89% of shoppers won’t return after a bad experience.

Third-party logistics providers (3PLs) offer solutions to these problems. They use dedicated facilities, standardized processes, and advanced technology to handle returns efficiently. Key benefits include:

- Dedicated Returns Facilities: Separate zones for returns prevent inventory mix-ups and warehouse congestion.

- Standardized Inspections: Grading systems quickly sort items for resale, refurbishment, or disposal.

- Fraud Prevention: Tools like Return Merchandise Authorization (RMA) systems and AI reduce fraud risks.

- Automation and Tracking: Warehouse Management Systems (WMS) and real-time tracking improve speed and accuracy.

- Data Insights: Analytics identify patterns (e.g., frequent returns) and optimize future operations.

Reverse Logistics Costs and Risks: Key Statistics for E-commerce Returns

Reverse Logistics and Returns Management Solution

Common Risks in Reverse Logistics

Reverse logistics comes with its own set of hurdles that can quickly drain resources and disrupt operations if not handled effectively. Unlike the straightforward path of forward logistics, where products move predictably from warehouse to customer, returns introduce unpredictable workflows that require specialized attention at every stage.

Operational Complexity and Errors

Handling returns is a labor-intensive process. Each item must be manually inspected, sorted, and evaluated to decide whether it should be restocked, refurbished, liquidated, or discarded. Without clear and standardized workflows, this process can spiral into chaos - 58% of businesses cite a lack of accountability in returns management as a key operational challenge.

But the challenges don’t end there. Returns often disrupt inventory tracking, leading to stock count errors as returned goods are mixed with new shipments. If returns aren’t processed in a designated area, they can cause warehouse clutter and bottlenecks, slowing down the picking and shipping of new orders. Transportation inefficiencies, such as "double handling" where items are moved multiple times before reaching their final destination, further complicate the process.

"A lack of clear returns policies and processes can be a major reverse logistics stumbling block for retailers, distributors and manufacturers alike."

– Abby Jenkins, Product Marketing Manager, NetSuite

These operational challenges directly drive up costs, making reverse logistics an expensive endeavor.

Cost Impact of Poor Returns Management

Inefficient returns management can become a financial black hole. The specialized labor required for unpacking, testing, cleaning, and relabeling returned items adds up quickly. During peak seasons, holiday returns alone are estimated to cost businesses $171 billion. On average, retailers face $165 million in return-related costs for every $1 billion in sales.

Delays in processing returned items create another costly issue: aging inventory that depreciates over time. This is especially problematic for seasonal or trendy products that lose value once their sales window closes. Despite these challenges, 80% of warehouses currently lack automation for handling returns, relying instead on manual processes that are far less efficient than forward logistics.

Then there’s the issue of fraud. For every $100 in returns, U.S. retailers lose $10.40 to return fraud. On top of that, 49% of retailers offer free return shipping to stay competitive, further increasing costs.

Customer Satisfaction Risks

Operational inefficiencies and rising costs don’t just impact the bottom line - they can also erode customer trust. A bad returns experience can leave a lasting negative impression. In fact, 89% of customers say they won’t shop with a retailer again after a poor returns experience, while 97% are likely to return if the process is smooth and hassle-free.

Returns policies also influence purchasing decisions. 11% of shoppers abandon their carts due to unsatisfactory return policies, and nearly 70% of customers review a retailer’s return policy before making a purchase. Once a return is initiated, transparency becomes critical. When customers can’t track the status of their return or refund, frustration builds. Alarmingly, 54% of e-commerce sites struggle with usability issues in their returns process.

"The progress of the order return process can be as important to users as the progress of the order itself, as users will be intensely focused on the status of their refund or exchange."

– Christian Holst, Research Director and Co-Founder, Baymard Institute

Delays in refunds or exchanges don’t just annoy customers - they can cost future sales. 7% of customers say they would never shop with a retailer again after a poor returns experience, while 13% say they’d be unlikely to return.

How 3PLs Reduce Reverse Logistics Risks

Reverse logistics can be a tricky process, with challenges like operational complexity, high costs, and unhappy customers. But third-party logistics providers (3PLs) have stepped in with tailored solutions to minimize these risks.

By leveraging specialized facilities, streamlined processes, and advanced technology, experienced 3PLs create systems that recover value from returned goods while safeguarding brands from fraud and operational hiccups. Here’s how they make it happen with dedicated spaces, efficient inspections, and robust fraud-prevention measures.

Specialized Returns Processing Facilities

Dedicated facilities are the backbone of effective reverse logistics. Top-tier 3PLs allocate specific warehouse zones exclusively for handling returns, keeping them separate from outbound shipping areas to avoid inventory mix-ups and congestion. These spaces are equipped with features like inspection stations, tools for testing functionality, and receiving docks designed specifically for returned items.

Without such dedicated zones, returns can disrupt outbound operations and eat up warehouse capacity - sometimes taking up 15–20% of usable space during peak seasons. This not only slows down new order shipments but also increases the risk of mixing returned items with fresh inventory.

Beyond basic sorting, advanced 3PLs operate value-added service (VAS) facilities where returned products are cleaned, repaired, and repackaged to be resold as "like-new" or "certified refurbished". For instance, clothing might be steamed and retagged, while electronics undergo functionality tests and reboxing. These extra steps allow brands to recover far more value compared to simply liquidating or discarding returned goods.

Consistent Inspection and Disposition Methods

Speed and consistency are key to maximizing the value of returned items. Leading 3PLs use 24-hour triage workflows to sort and grade returns within a day of receipt, which accelerates customer refunds and resale opportunities. This is a stark contrast to industry averages, where only 37% of returns are processed within a day and 42% within a week.

To ensure accuracy, items are graded based on standardized criteria:

- A-Grade: Perfect condition items are restocked for full-price resale.

- B-Grade: Lightly used or slightly damaged items are refurbished or sold at a discount.

- C-Grade: Usable items that can’t be sold as new are liquidated through secondary channels.

- D-Grade: Defective or unsalvageable items are scrapped, recycled, or returned to vendors for credit.

Technology plays a big role here. Handheld devices and Warehouse Management Systems (WMS) streamline inspections by providing checklists and automatically assigning disposition codes based on item conditions. Photo documentation at grading stations adds an extra layer of accountability, serving as evidence for warranty claims, fraud investigations, or customer disputes. Once graded, these systems seamlessly direct items to their next step - whether that’s restocking, repair, liquidation, or disposal.

Given that nearly 47% of warehouse operators cite returns management as their biggest challenge, such standardization is a game-changer.

Fraud Detection and Policy Enforcement

Returns fraud is a costly problem, with U.S. retailers losing $101 billion to it in 2023. That’s why fraud detection is a critical element of reverse logistics. It starts with Return Merchandise Authorization (RMA) systems, which verify return eligibility before items are shipped back. These systems ensure returns fall within the allowed timeframe, match the original order, and comply with brand-specific rules, such as requiring original tags.

On the ground, 3PL staff conduct physical checks, verifying serial numbers against outbound records and looking for signs of wardrobing or counterfeit swaps. Technology adds another layer of protection.

Advanced platforms use AI and machine learning to spot patterns, such as identifying customers who frequently abuse return policies or make repeated “damaged on arrival” claims. For example, "bracketing", where customers order multiple sizes with the intent to return most, can be flagged. A practical success story: In 2024, Gunner Kennels reduced its return rate by 5% and boosted order conversions by 40% by using 3D and AR tools to help customers select the right dog crate size before buying.

Photo documentation also plays a vital role, creating an audit trail for chargeback disputes and ensuring return policies are enforced consistently without straining customer relationships.

sbb-itb-eb0f906

Technology Tools for Reverse Logistics

Automation and Real-Time Tracking

Technology plays a crucial role in reducing risks and improving efficiency in reverse logistics. Leading third-party logistics providers (3PLs) rely on Warehouse Management Systems (WMS) and Returns Management Systems (RMS) to manage returned items from the moment they arrive. These systems update inventory records and enforce return policies automatically. Automated sorting systems, equipped with robotics and scanners, classify returns for repair, repackaging, recycling, or resale. These systems handle larger volumes at a faster pace than manual processing. Additionally, Automated Storage and Retrieval Systems (AS/RS) utilize shuttles and mini-loaders to efficiently store and retrieve items, minimizing the chances of inventory loss.

Real-time tracking, powered by GPS and IoT devices, provides precise location data and estimated arrival times. This information helps warehouses allocate labor and resources more effectively. Technologies like RFID and barcode scanning log return reasons without requiring packages to be opened - a practice adopted by 44% of companies.

"Warehouse automation can aid reverse logistics by enhancing processes for returns or exchanges." – Justin Dunwiddie, Ryder

The financial impact of these tools is significant. Companies using automation can recover between 9% and 15% of revenues that might otherwise be lost. Considering that processing a single return can cost 20% to 65% of the item's original value, automation offers a clear path to improving profitability.

Data Analysis for Process Improvement

Data analysis transforms return data into actionable insights, enabling companies to address underlying issues and refine their strategies. Using AI and machine learning, businesses assess factors like item condition, purchase history, and resale value to determine the best course of action - whether that’s refurbishment, resale, donation, or disposal. Predictive analytics help forecast return volumes, allowing for better resource planning during peak seasons. Currently, 25% of companies are leveraging these predictive tools. Data also highlights trends like "bracketing", where customers buy multiple sizes or colors with the intention of returning most. By identifying this pattern, brands can revise policies or enhance sizing guides to reduce future returns.

Root cause analysis digs deeper into why returns happen. For example, in 2025, Supplement Warehouse discovered that unclear labeling on vitamins was leading to customer confusion and returns. Former Marketing Manager Brian Anderson addressed this by redesigning the labels to be larger and more visible online, significantly reducing returns tied to ingredient misunderstandings. Similarly, when data reveals high damage rates for specific items, fulfillment teams can adjust packaging to prevent further issues.

"Combining all your sales and returns data uncovers different patterns, like which products get returned most and why, so you can better prepare and prevent future returns." – Shopify

For e-commerce brands working with multiple 3PL partners, platforms like Forthmatch offer valuable tools. These platforms provide real-time analytics and historical benchmarks for service level agreements (SLAs). Merchants can track shipping speeds, pinpoint causes of delays, and create data-driven reports for contract negotiations. This approach shifts reverse logistics from being a reactive process to one that integrates seamlessly with broader e-commerce operations, driving accountability and continuous improvement.

Connecting Reverse Logistics with E-Commerce Platforms

Today’s 3PLs are bridging the gap between their Warehouse Management Systems (WMS) and e-commerce platforms like Shopify using APIs and integrated tools. This connection streamlines the entire returns process - from the moment a customer initiates a return to the inspection and restocking of the item. For instance, when a customer starts a return through a portal, the system can automatically generate an RMA and issue a prepaid shipping label, ensuring everything flows smoothly.

One standout advantage of this integration is real-time inventory updates. As soon as an item is inspected and cleared, Shopify’s inventory is updated instantly. This quick turnaround minimizes downtime and helps prevent losses, especially for seasonal products. It's worth noting that 35% of refunds across Shopify businesses are now processed through apps rather than manual methods.

Customer communication also gets a major upgrade. When a returned item reaches the warehouse, the system automatically updates customers on the status - whether it’s been received, inspected, or refunded. This automation reduces the dreaded “Where is my refund?” inquiries. In fact, 96% of shoppers who experienced a smooth returns process said they’d return to buy from the same retailer again.

Take Gunner Kennels, for example - they managed to cut their return rate by 5%. Another case is The Dad Hoodie, which used Shopify Fulfillment Network to handle inspection and restocking, saving valuable time and effort.

For merchants juggling multiple 3PL partners, platforms like Forthmatch offer even more control. Forthmatch integrates with Shopify to monitor fulfillment performance, flag SLA breaches, and identify delays in reverse logistics. By tying reverse logistics to e-commerce platforms, 3PLs not only improve their internal operations but also give merchants the tools to negotiate stronger SLAs. This data becomes a powerful asset during contract discussions or when evaluating potential new providers.

Conclusion: How 3PLs Lower Risks and Improve Results

Third-party logistics providers (3PLs) help reduce risks in reverse logistics by using specialized facilities and standardized workflows. These workflows sort returns within 24 hours into categories like resale, refurbishment, liquidation, or scrap, all while relying on integrated technology to streamline the process.

With tools like advanced automation and real-time tracking, reverse logistics transitions from a reactive process to proactive management. This approach is crucial for protecting profit margins, especially when losses can reach $165 million for every $1 billion in sales. Automated sorting systems efficiently handle seasonal spikes, while real-time tracking ensures returned items are promptly updated in inventory systems.

Data-driven monitoring plays a key role in accountability. A surprising 58% of businesses report issues with tracking returns, but transparent performance metrics from 3PLs empower brands to negotiate better contracts and address recurring problems that may cause customer dissatisfaction. For instance, tools like Forthmatch, which integrate with Shopify, can monitor return-cycle times, flag SLA violations, and provide concrete data for negotiations. If 15% of orders miss the 24-hour processing window, brands can use this data to shift conversations from vague assumptions to actionable insights.

Successful brands focus on key metrics like resale capture rates, cost per return, and root cause analysis. These insights not only hold 3PLs accountable but also uncover patterns - like frequent sizing issues or carrier delays - that could lead to customer loss. Considering that 67% of customers will avoid a business after a single bad return experience, tracking performance is an investment in retaining customers and boosting their lifetime value. By tapping into 3PL expertise, brands can not only reduce risks but also strengthen long-term customer relationships.

FAQs

How can 3PLs help e-commerce businesses lower the costs of handling returns?

Third-party logistics (3PL) providers play a crucial role in helping e-commerce businesses reduce the costs associated with reverse logistics. By fine-tuning returns processes and boosting operational efficiency, they make managing returns far less of a headache. How? Through tools like data analytics, automation, and system-driven workflows, 3PLs can cut down on errors, speed up the returns process, and keep storage and handling costs in check.

Beyond just handling returns, 3PLs offer valuable insights into return patterns. These insights help businesses pinpoint recurring issues and tackle them at the source. This kind of proactive strategy not only cuts down on unnecessary returns but also improves cost management, making the entire reverse logistics process smoother and more economical.

How does technology improve reverse logistics efficiency?

Technology has become a game-changer in simplifying reverse logistics by automating processes and offering valuable insights. With real-time tracking, businesses gain clear visibility into returns, while automation accelerates sorting and processing tasks. Advanced data analytics also play a key role, helping companies anticipate return patterns, fine-tune inventory management, and cut down on waste. On top of that, AI-powered tools enhance decision-making and operational precision, making everything run more smoothly.

By tapping into these technological tools, e-commerce brands can cut delays, lower expenses, and provide a more seamless returns experience for their customers.

How do 3PLs help e-commerce businesses reduce the risk of returns fraud?

Third-party logistics (3PL) providers are essential allies in tackling the issue of returns fraud. By utilizing advanced systems, they can identify suspicious patterns and stop fraudulent activities before they escalate. These providers equip e-commerce businesses with data-driven tools that not only detect fraud but also monitor return behaviors and flag unusual trends as they happen.

Beyond technology, 3PLs also support businesses in creating well-defined and enforceable return policies. These policies act as a deterrent to fraudulent schemes while still prioritizing a positive customer experience. By blending cutting-edge technology with operational know-how, 3PLs enable businesses to stay one step ahead and reduce the risks tied to fraudulent returns.