Real-time tracking is no longer optional for direct-to-consumer (DTC) brands. It’s what 96% of customers expect when monitoring their orders. This technology gives buyers live updates on their package’s journey, building trust and reducing customer service inquiries. For brands, it means fewer errors, faster deliveries, and better performance insights.

Here’s how third-party logistics (3PLs) make it happen:

- Warehouse Management Systems (WMS): Automates inventory updates with barcode scans, ensuring accuracy above 99.5%.

- Distributed Order Management (DOM): Routes orders to the closest fulfillment center, cutting shipping times and costs.

- E-Commerce Integrations: Syncs with platforms like Shopify and carriers like UPS for seamless updates.

- GPS and IoT Sensors: Tracks vehicles and monitors sensitive shipments like perishables.

The result? Brands reduce “Where is my order?” calls by up to 70%, improve delivery times, and boost customer retention. Tools like Forthmatch even help monitor 3PL performance to ensure on-time deliveries and order accuracy.

Real-time tracking isn’t just about visibility - it transforms how brands operate and serve customers.

How a 3PL Works [E-commerce Fulfillment Process Explained]

Technologies 3PLs Use for Real-Time Tracking

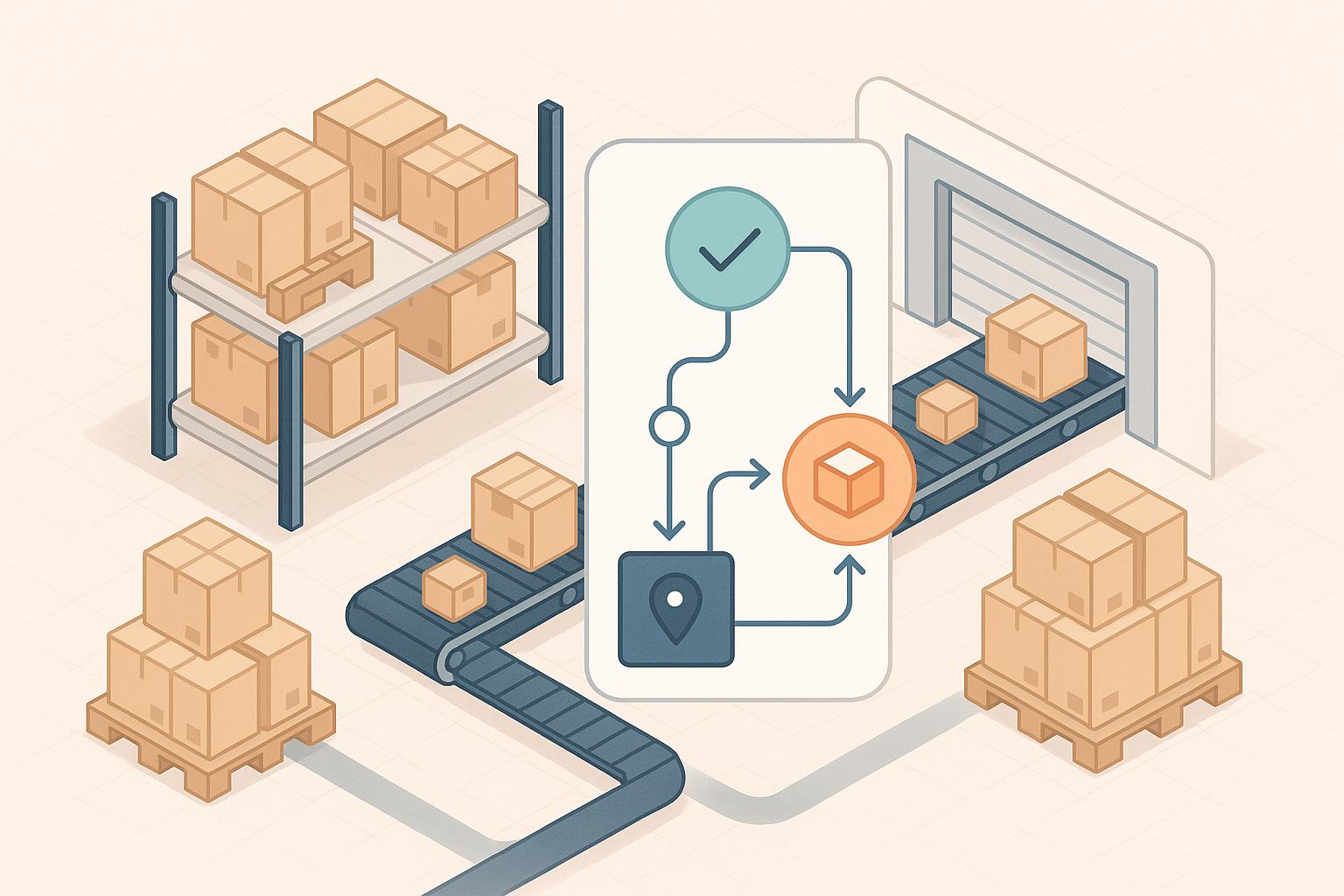

Real-time tracking hinges on advanced systems that follow inventory every step of the way - from the warehouse shelf to the customer’s doorstep. At the heart of this process, Warehouse Management Systems (WMS) act as the central command, integrating with cloud platforms to synchronize data across multiple warehouses and sales channels like Shopify and Amazon. This ensures inventory levels remain accurate and avoids issues like overselling.

Warehouse Management Systems and Inventory Syncing

A WMS is essentially the operational brain of a fulfillment center. It oversees all inventory movements and provides live updates on stock levels across various locations. Every barcode scan - whether during receiving, picking, or loading - feeds real-time data into the system. By automating these updates, manual errors are nearly eliminated, allowing high-performing 3PLs to achieve order accuracy rates exceeding 99.5%.

"WMS solutions act as a central hub for your supply chain data, seamlessly integrating information from various sources throughout your fulfillment network." - Erhan Musaoglu, CEO, Logiwa

Cloud-based syncing ensures that when a customer places an order, inventory is instantly reserved and updated across the network. This unified view of inventory not only prevents overselling but also keeps stock counts accurate across all platforms. Combined with live updates, advanced order routing takes efficiency to the next level.

Distributed Order Management for Multi-Location Fulfillment

Distributed Order Management (DOM) systems bring intelligence to the routing process, deciding which fulfillment center should handle an order. When an order comes in, DOM evaluates factors like customer location, inventory availability, and shipping costs to assign the best fulfillment center. This “multi-node” approach minimizes shipping zones, reduces costs, and speeds up delivery by shipping from the closest location to the customer.

For example, one retailer cut fulfillment times from 10 days to under two, while another handled 35% of their annual BOPIS (Buy Online, Pick Up In Store) volume in just one quarter. Efficient routing like this ensures smooth handoffs to carriers and faster delivery.

E-Commerce Platform and Carrier Integrations

APIs and EDI integrations connect 3PL software directly with e-commerce platforms and shipping carriers like UPS, FedEx, and USPS. These connections automate tasks like syncing order data, creating shipping labels with tracking barcodes, and sending real-time updates to customers via email or SMS. Each time a package is scanned - whether it’s picked up, in transit, or delivered - the data flows back through the API to update the customer’s tracking portal.

Leading 3PLs also leverage GPS and telematics to provide live location data for delivery vehicles, offering precise ETAs and even live map views of shipments. For sensitive goods like pharmaceuticals or perishables, some are incorporating IoT sensors to monitor conditions like temperature and humidity. These technologies eliminate the need for manual updates and drastically reduce "Where is my order?" inquiries by up to 60%. Together, these integrations form the backbone of an efficient, customer-focused fulfillment process.

Performance Improvements from Real-Time Tracking

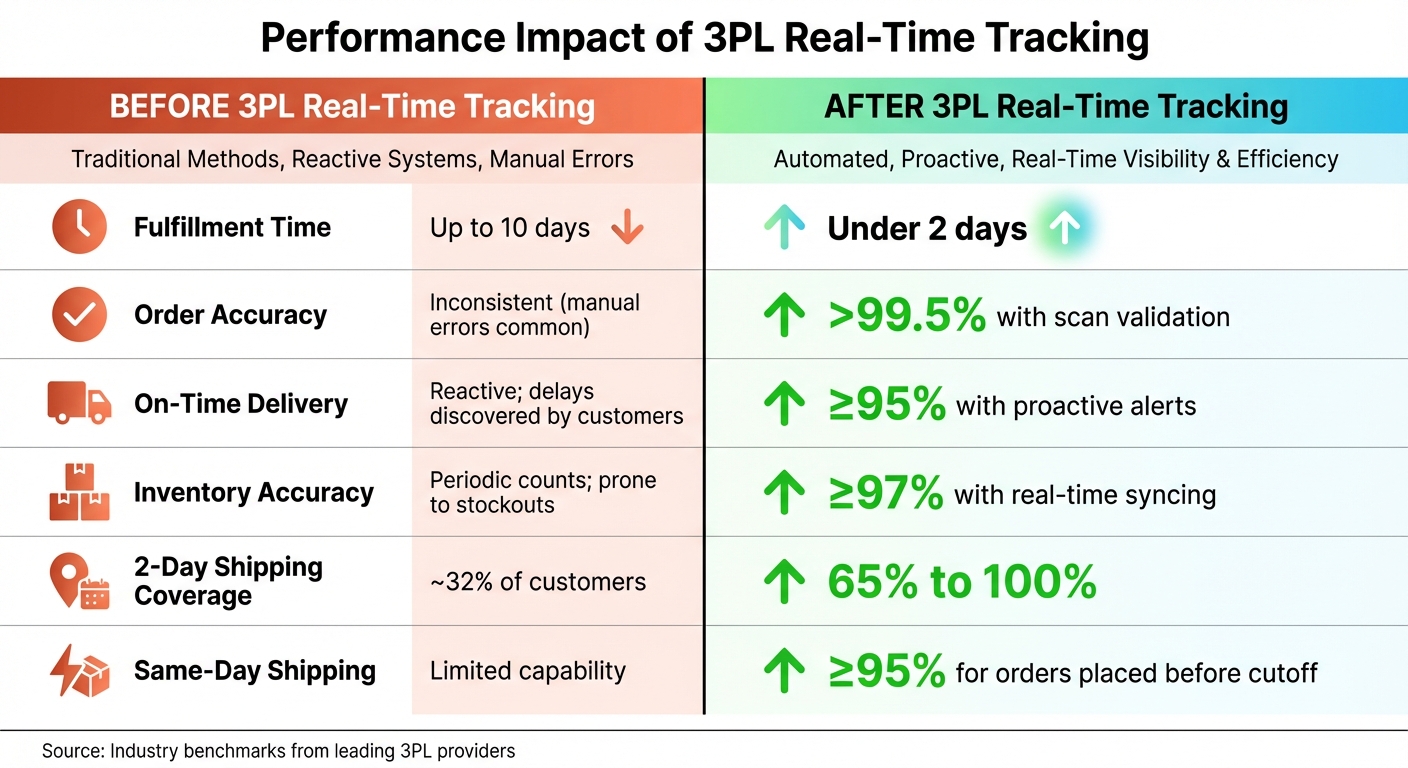

Before and After 3PL Real-Time Tracking Performance Metrics

Operational Metrics Improved by Real-Time Tracking

Real-time tracking is a game-changer for DTC brands aiming to streamline their operations. Leading 3PLs consistently maintain order accuracy rates above 99.5% through the use of barcode scanning and automated validation systems. On-time delivery rates hit 95% or higher, thanks to proactive monitoring of carrier performance and addressing delays before customers even realize there's an issue. Inventory accuracy also sees a boost, climbing to 97% or more with live SKU updates, which helps avoid costly problems like stockouts or overstocking.

This shift from a reactive to a proactive management style is transformative. With real-time visibility, businesses can adopt "management by exception" strategies, focusing only on anomalies rather than micromanaging every detail. This approach significantly reduces operational costs by cutting down on customer service inquiries, lost package claims, and expenses related to returns. Plus, with 96% of consumers actively tracking their orders and 87.4% stating that tracking enhances their shopping experience, these operational improvements directly contribute to higher customer satisfaction.

The operational benefits don’t stop there - they also ripple out to impact revenue and cost structures in measurable ways.

Revenue and Cost Impact

The financial upside of real-time tracking extends well beyond improving efficiency. Consider this: nearly 40% of customers abandon a brand after a single poor delivery experience, making precise tracking essential for retaining revenue. On the cost-saving side, the numbers are equally compelling. Pablo Gabatto, Business Operations Manager at Ample Foods, shared that introducing a second fulfillment center with real-time analytics expanded their 2-day shipping coverage from 32% to 65%, all while cutting costs by 13%. Similarly, using real-time demand data to strategically distribute inventory can deliver bottom-line savings of 13% or more.

Before and After: Performance Metrics Comparison

The table below highlights the dramatic improvements businesses experience when adopting 3PL real-time tracking:

| Metric | Before 3PL Real-Time Tracking | After 3PL Real-Time Tracking |

|---|---|---|

| Fulfillment Time | Up to 10 days | Under 2 days |

| Order Accuracy | Inconsistent (manual errors common) | >99.5% with scan validation |

| On-Time Delivery | Reactive; delays discovered by customers | ≥95% with proactive alerts |

| Inventory Accuracy | Periodic counts; prone to stockouts | ≥97% with real-time syncing |

| 2-Day Shipping Coverage | ~32% of customers | 65% to 100% |

| Same-Day Shipping | Limited capability | ≥95% for orders placed before cutoff |

Brands like NZXT have seen firsthand the impact of these improvements. By integrating real-time fulfillment technology, they slashed their fulfillment times from 10 days to less than two. Similarly, Parachute leveraged real-time inventory visibility to process 1,300 click-and-collect orders in Q4 2024 alone - accounting for 35% of their annual BOPIS volume across their omnichannel network. These examples underline how real-time tracking doesn’t just optimize operations - it transforms the customer experience.

sbb-itb-eb0f906

Multi-Channel Order Tracking and Centralized Dashboards

Centralized dashboards are a game-changer when it comes to managing orders across multiple sales channels. They simplify operations and provide much-needed clarity in a complex environment.

Centralized Dashboards for Cross-Platform Visibility

Managing orders from various sales channels can quickly turn into chaos without the right tools. Centralized dashboards solve this problem by bringing all order data into one easy-to-navigate interface. This unified system acts as a single source of truth, helping businesses avoid common pitfalls like overselling, missed shipments, or unhappy customers caused by fragmented information silos.

By integrating APIs, a 3PL’s warehouse management system (WMS) connects seamlessly with e-commerce platforms, ensuring inventory data stays synchronized. For example, when a product sells on one platform, inventory levels across all channels update instantly. This synchronization is further enhanced with live tracking tools that monitor goods from picking to delivery.

For companies juggling inventory across multiple fulfillment centers, this kind of visibility is essential. Take Gerard Ecker, CEO of Ocean & Co., as an example. After losing track of 1,500 units with a previous provider, he switched to a tech-driven 3PL that offered full dashboard transparency. This shift gave him complete oversight of operations, including real-time inventory updates and order tracking. Centralized dashboards ensure consistency across platforms, complementing real-time tracking with reliable data.

Automated Workflows for Order Management

While dashboards provide a clear overview, automated workflows take efficiency to the next level by handling repetitive tasks. These workflows save hours of manual labor by automating processes like generating shipping labels and routing orders to the best fulfillment center based on stock levels or delivery zones. Once a shipment is dispatched, tracking numbers are automatically sent to customers via email or SMS, cutting down on “Where Is My Order” (WISMO) inquiries.

"I used to have to pull inventory numbers from three places every day and move all the disparate data into a spreadsheet. ShipBob has an analytics tab in their dashboard with all of this information, which is great for end-of-month reconciliations." - Wes Brown, Head of Operations, Black Claw LLC

"ShipBob's analytics tool is really cool. It helps us a lot with planning inventory reorders, seeing when SKUs are going to run out, and we can even set up email notifications so that we're alerted when a SKU has less than a certain quantity left." - Oded Harth, CEO, MDacne

These workflows also enable businesses to address issues proactively. Instead of waiting for customer complaints to uncover problems, the system flags potential delays, fulfillment errors, or low stock levels in real time. This allows brands to resolve issues before they affect the customer experience. For direct-to-consumer (DTC) brands operating across multiple channels, this shift from reactive to proactive management significantly improves operational efficiency.

Customer Impact and Research Findings

Customer Satisfaction and Retention Improvements

Real-time tracking has turned delivery from a source of stress into a source of reassurance. When customers can see exactly where their package is and get an estimated arrival time, they feel more in control. It’s no surprise that 96% of consumers actively track their orders, and 87.4% say real-time tracking makes their buying experience more enjoyable.

This added transparency also builds stronger brand loyalty. Studies show that 59.3% of shoppers feel more loyal to brands offering real-time tracking, and 24.6% are highly likely to shop again when this feature is available. Emil Prigge, Product Engineer at Oco Meals, summed it up well:

"It's a promise. We promise to be here at this time. And then they [the customers] can always check in on that promise."

Beyond improving customer satisfaction, real-time tracking has a direct impact on operational efficiency. Brands report up to a 70% drop in customer service calls, significantly reducing the strain on support teams. This is especially important when you consider that 40% of customers stop doing business with a company after just one negative experience.

Research Data on Real-Time Tracking Benefits

The numbers behind real-time tracking tell a clear story. More than 75% of shoppers check their tracking information multiple times during a delivery. This shows how critical the tracking phase is to the overall customer journey.

The financial implications are just as striking. Seventy-four percent of consumers say their opinion of a company worsens if a package isn’t delivered as promised, and 88% abandon online carts due to poor shipping options. On the flip side, companies delivering exceptional customer experiences can charge a 16% price premium.

| Metric | Before | After |

|---|---|---|

| Customer Service Calls | High volume of WISMO inquiries | Up to 70% reduction |

| Brand Loyalty Impact | 40% churn risk after one bad experience | 59.3% positive loyalty boost |

| Customer Experience | Anxiety and uncertainty | 87.4% report a better experience |

| Repeat Purchase Intent | Lower likelihood of returns | 24.6% extremely likely to return |

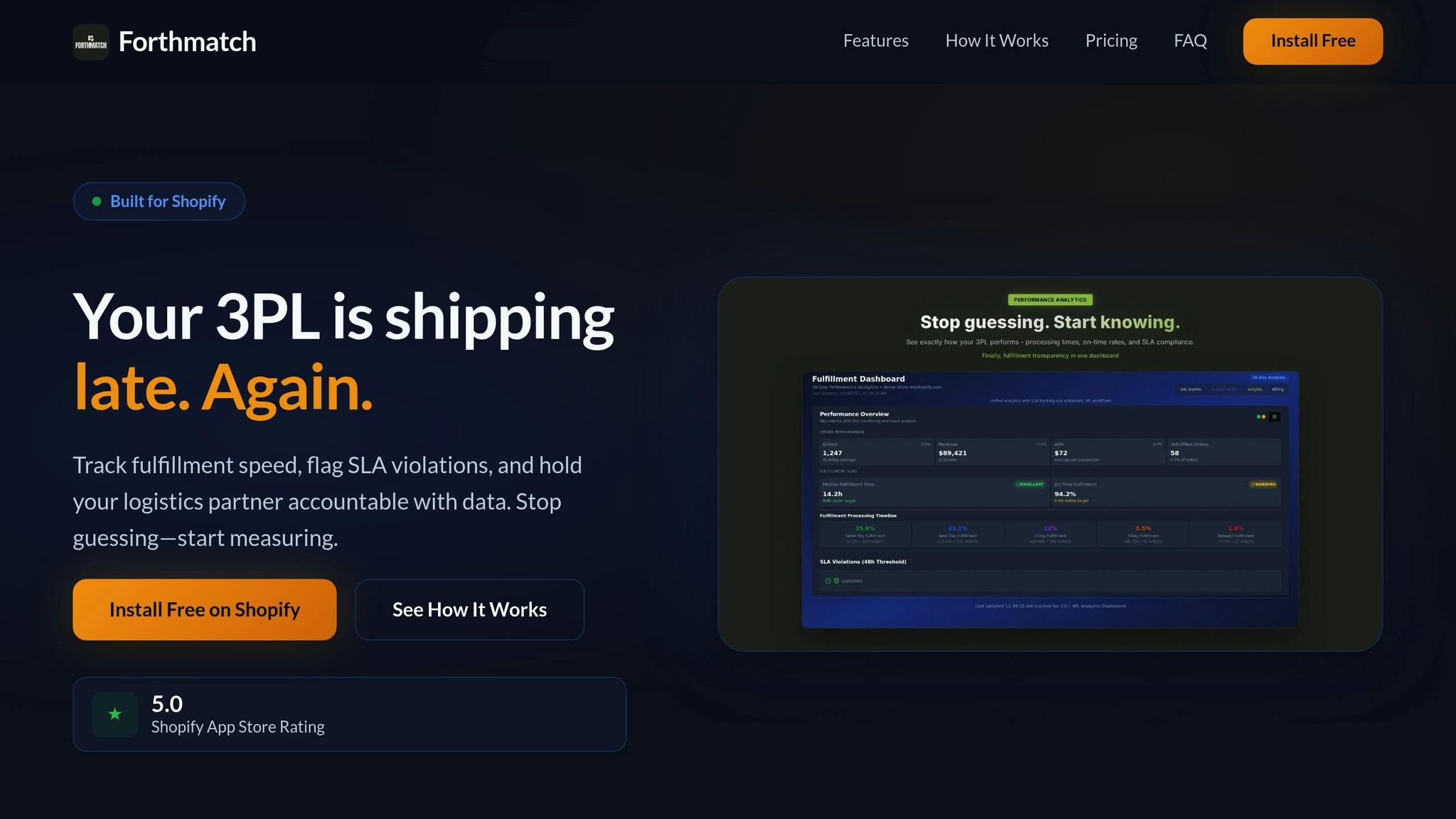

This data highlights the importance of keeping delivery performance on track, which is where Forthmatch steps in.

How Forthmatch Helps DTC Brands Monitor 3PL Performance

The benefits of real-time tracking for customers depend on operational precision. While tracking provides visibility to shoppers, brands need to ensure their third-party logistics (3PL) partners consistently meet delivery expectations. That’s where Forthmatch comes into play.

Forthmatch offers a centralized platform to monitor 3PL performance against Service Level Agreements (SLAs). It flags when key metrics - like 99.5% order accuracy or 95% on-time delivery - fall short. This allows brands to hold logistics partners accountable and address problems before they escalate.

The platform also generates detailed reports to identify bottlenecks. For example, if a 3PL frequently misses same-day shipping targets on Fridays, Forthmatch captures that data, creating a clear record for discussions. This level of oversight is crucial because 85% of consumers say they won’t shop with a retailer again after a poor delivery experience. Plus, inefficient handoffs between shippers and carriers cost the U.S. logistics industry a staggering $95 billion annually.

Conclusion: Using 3PLs for Real-Time Tracking Success

Real-time tracking has become a must-have for DTC brands. With 96% of consumers tracking their orders and 87.4% saying it improves their experience, it’s clear that visibility plays a critical role in meeting customer expectations. Partnering with 3PLs that offer live updates at every stage - from picking and packing to final delivery - gives brands the transparency they need to build trust and streamline operations.

This level of insight doesn’t just enhance customer satisfaction; it also helps brands identify bottlenecks, better manage inventory across multiple centers, and cut down on shipping costs. For example, some brands have seen fulfillment times drop from 10 days to under two, while expanding 2-day shipping coverage significantly.

But transparency alone isn’t enough. Brands need to ensure accountability by using objective performance metrics to avoid decision-making based on assumptions. As Chris Jarvis, Chief Operations Officer at GoBolt, explained:

"Lifting the veil for brands and shoppers depends on a 3PL's ability to track and analyze valid, complete data".

Reliable data empowers brands to act decisively. Tools like Forthmatch can automatically monitor shipping times and flag SLA breaches, turning vague concerns into actionable insights for constructive conversations with logistics partners.

FAQs

How do Warehouse Management Systems (WMS) help DTC brands improve order accuracy?

Warehouse Management Systems (WMS) play a crucial role in boosting order accuracy for direct-to-consumer (DTC) brands. They simplify fulfillment tasks, reduce human error, and make the entire process more efficient. Key features like automated pick-and-pack workflows, real-time inventory tracking, and validation checks help ensure that the correct items are picked, packed, and shipped every time.

With a WMS in place, DTC brands can cut down on costly mistakes, streamline operations, and provide a smoother, more reliable customer experience. This kind of precision is especially important for growing e-commerce businesses, where maintaining customer trust and satisfaction is non-negotiable.

How does Distributed Order Management (DOM) help speed up shipping for DTC brands?

Distributed Order Management (DOM) speeds up shipping by directing orders to the nearest or most efficient fulfillment center. Leveraging real-time inventory insights and set routing rules, DOM ensures that orders are shipped from the best possible location, reducing delivery times and improving the overall shopping experience.

By simplifying the fulfillment process, DOM helps eliminate unnecessary delays, creating a quicker and more dependable order-to-delivery cycle - essential for keeping up with the demands of today’s direct-to-consumer (DTC) shoppers.

How does real-time tracking improve customer satisfaction and loyalty?

Real-time tracking greatly improves the customer experience by providing precise, up-to-the-minute updates on order status. This level of transparency eliminates guesswork, fosters trust, and gives customers a sense of control over their purchases.

When customers have a clear idea of when their deliveries will arrive, it reduces the stress of unexpected delays or missed deadlines. This smoother experience not only boosts customer satisfaction but also deepens loyalty, making them more likely to return for future purchases and build lasting relationships with the brand.