Automation is transforming how third-party logistics (3PL) providers handle order processing. By replacing manual tasks with tools like Robotic Process Automation (RPA), Warehouse Management Systems (WMS), and Order Management Systems (OMS), 3PLs can process orders faster, reduce errors, and save costs. Here are the key takeaways:

- Speed: Automated systems process orders in as little as 15–30 minutes, compared to 8–12 hours manually.

- Cost Efficiency: Automation reduces order processing costs from $30–$60 per order to $5–$10.

- Accuracy: Barcode scanning and real-time syncing bring error rates close to zero.

- Scalability: Automation handles seasonal spikes without additional staff.

For example, companies like Ryder and ShipMonk use robotics and AI to improve picking, packing, and shipping, achieving near-perfect accuracy and significant cost savings.

These tools integrate seamlessly with platforms like Shopify and Amazon, ensuring real-time inventory updates and preventing overselling. Automation isn't just faster - it's also more reliable, helping 3PLs meet growing e-commerce demands.

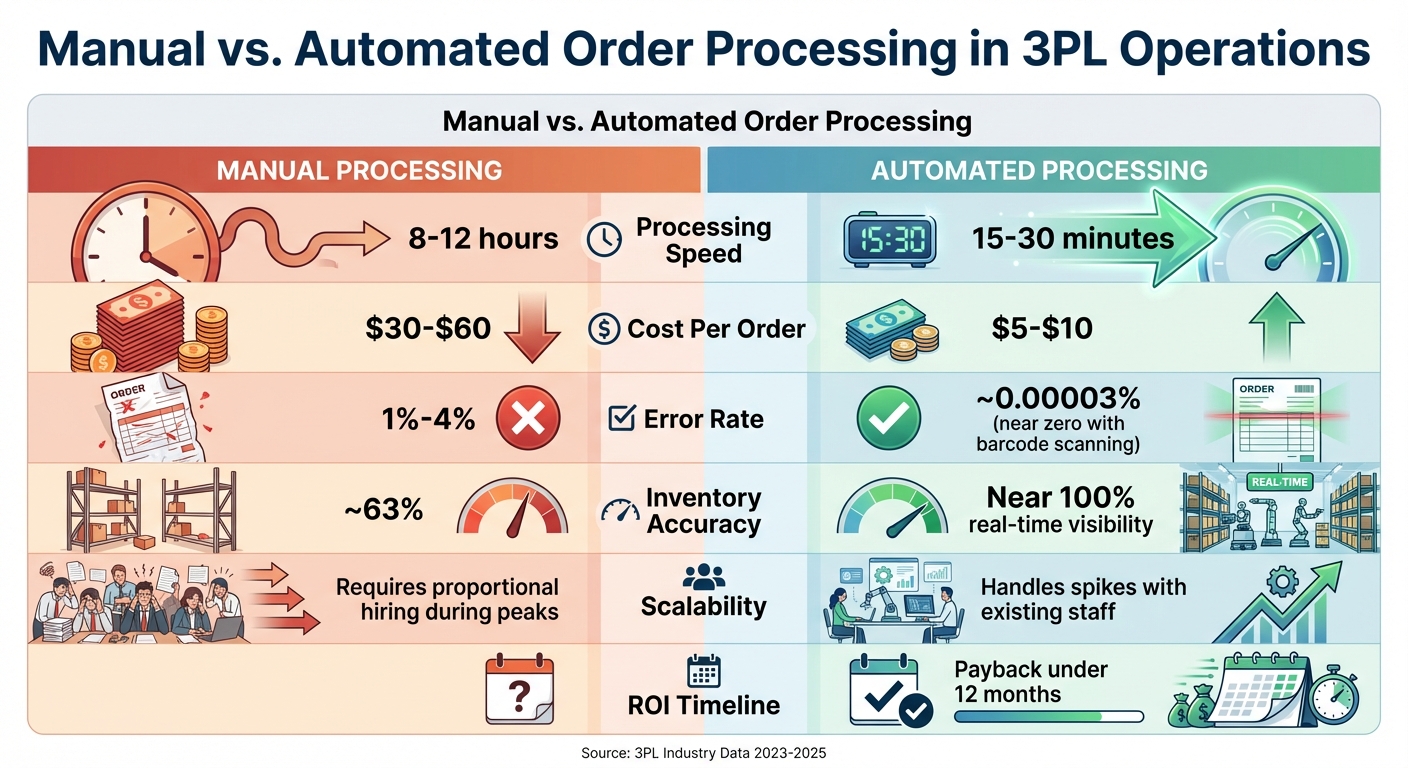

Manual vs Automated 3PL Order Processing: Cost, Speed, and Accuracy Comparison

How Are 3PLs Embracing Warehouse Automation and AI?

Main Automation Tools 3PLs Use

Third-party logistics providers (3PLs) rely on automation tools to cut down manual tasks and speed up order processing. These tools work together, each playing a unique role in turning an order into a shipment in just hours rather than days. From receiving an order to shipping it out, automation simplifies the entire fulfillment process.

Robotic Process Automation (RPA)

RPA takes over repetitive back-office tasks, saving time and reducing mistakes. Think of tasks like entering orders, validating data, generating invoices, or syncing information across disconnected systems - RPA handles all of this automatically. For instance, instead of manually transferring order details from platforms like Shopify or juggling multiple spreadsheets, RPA software does the heavy lifting. This not only eliminates typos and missed updates but also prevents shipping errors or overselling inventory. For 3PLs managing a variety of clients using different systems, RPA acts as a bridge, ensuring smooth data flow between siloed platforms. This seamless transfer of information lays the foundation for efficient warehouse operations.

Warehouse Management Systems (WMS)

A WMS focuses on streamlining the physical side of fulfillment, making warehouse workflows faster and more efficient. It handles everything from receiving and organizing inventory to tracking stock levels and guiding workers through optimized picking and packing routes. For example, when a worker scans a barcode, the system updates inventory instantly and directs them to the next item, cutting down unnecessary travel time. Ryder’s use of 150 LocusBots is a great example - these bots shaved 20 seconds off pick times per unit. By keeping inventory data accurate and directing operations in real time, a WMS ensures orders are fulfilled with precision.

Order Management Systems (OMS)

An OMS acts as the central hub for managing orders, ensuring quick and accurate processing from start to finish. It gathers orders from various sales channels - like Shopify, Amazon, TikTok Shop, and even physical stores - and routes them to the most suitable fulfillment center based on stock availability and customer location. Beyond routing, it automates tasks like payment processing, shipping label creation, carrier selection, and customer notifications. For example, Edikted’s COO, Zvika Alon, implemented a two-way integration between the brand’s Shopify store and Ryder’s WMS in January 2023. This setup allowed orders to be automatically assigned to fulfillment centers, enabling immediate processing and avoiding inventory mishaps like double-selling.

Jon-Mark Craddock, Director of Logistics at Tuckernuck, shared his thoughts on Ryder’s automated order routing in January 2023:

"Order Rules are a fantastic example of how intuitive the Ryder platform is. I was able to set up our core shipping strategy with no programming experience whatsoever."

How Automated Order Processing Works

Automation tools have revolutionized the way orders move from placement to delivery, often completing the process in just a few hours. By minimizing human involvement, these systems not only speed up operations but also reduce common errors like overselling or incorrect shipping details.

Order Capture and Synchronization

As soon as a customer hits "Buy" on platforms like Shopify or Amazon, the order details instantly flow into the 3PL's system. Thanks to webhooks - which act as event-driven triggers - this data transfer happens in seconds, bypassing the delays of traditional nightly updates. The Order Management System (OMS) serves as the central hub, collecting everything from customer details and product information to discounts, taxes, and shipping preferences across all connected platforms.

During this phase, SKU mapping ensures that each product variant from the online store is matched to its corresponding warehouse barcode. This guarantees that warehouse workers pick the correct item every time. Additionally, inventory levels are updated across all sales channels in real time, helping to prevent overselling. For brands operating on multiple platforms, this instant synchronization is crucial - 22% of online shoppers abandon their carts if the delivery timeline seems too slow.

Take Nomad Goods, for example. In 2023, the company adopted Extensiv's order management tools to support its global growth. The result? A 14.6% increase in Shopify orders and a 125% jump in Amazon order volume, all thanks to real-time visibility across multiple warehouses.

Inventory Check and Allocation

Once an order is captured, the Warehouse Management System (WMS) confirms the item's availability and identifies its exact location on a shelf. The system then reserves those items specifically for the order, ensuring they aren't sold to someone else. Intelligent routing logic determines which warehouse should fulfill the order, factoring in inventory levels, customer location, and shipping costs. If stock in a warehouse drops below a set threshold, the system can trigger alerts or even place replenishment orders automatically.

For instance, Bulu Group implemented Extensiv 3PL Warehouse Manager and SmartScan in 2023. This move boosted labor efficiency by 25% and cut billing time in half, thanks to streamlined order processing. These automated checks and allocations set the stage for smooth picking and packing.

Routing, Picking, and Packing

After inventory is allocated, the WMS generates optimized picking routes and sends digital pick lists to warehouse workers. Instead of wandering aimlessly, pickers follow mapped paths designed to save time. Tools like pick-to-light systems use visual cues to guide workers to the right shelf, while Autonomous Mobile Robots (AMRs) transport items between zones, reducing physical strain and speeding up the process.

Accuracy is a top priority. Barcode scanning at every step ensures the right items are picked and updates inventory in real time. This meticulous approach helps 3PLs achieve pick accuracy rates of 99.8% or higher. For example, ShipMonk boasts a 99.9% accuracy rate across its automated facilities.

Packing is just as streamlined. Systems like Cubiscan use infrared technology to measure product dimensions and recommend the best box size, cutting down on packaging waste and reducing shipping costs tied to dimensional weight. Automated label printers and "Print and Apply" systems handle shipping labels, eliminating manual steps that could slow things down. Each automated action not only speeds up the process but also ensures orders are packed correctly.

Shipping and Tracking Updates

Once packing is complete, the system moves on to shipping. It evaluates carrier rates and service levels in real time to pick the most cost-effective option that meets delivery deadlines. High-speed sorters then direct packages into the correct carrier lanes, ensuring quick hand-offs.

As soon as a carrier scans the package, the system sends tracking updates to the customer via email or SMS. These real-time updates reduce "Where Is My Order?" (WISMO) inquiries. Customers are kept in the loop at every stage, from label creation to delivery.

Doris Sleep founder Tracey Wallace experienced the benefits firsthand with ShipBob's automated system. In one instance, an influencer received a shipping confirmation email just one hour after placing an order. Wallace credited this speed to the 3PL's automation and real-time tracking capabilities.

"An hour after an influencer ordered from me, he had already received an email saying his order had shipped. If I was fulfilling orders myself, it would have taken me much longer." - Tracey Wallace, Founder, Doris Sleep

These examples highlight how technology integration continues to drive innovation in 3PL operations.

Benefits of Automation in Order Processing

Using tools like RPA, WMS, and OMS doesn’t just make operations smoother - it delivers faster results, lowers costs, and improves accuracy. One of the biggest advantages is speed. Automated systems handle orders in just 15 to 30 minutes, compared to the 8 to 12 hours it takes with manual workflows. This faster turnaround directly enhances customer satisfaction and loyalty.

Cost savings are another major advantage. While manual processes cost between $30.00 and $60.00 per order, automation slashes that down to $5.00–$10.00 per order. These savings come from cutting out repetitive tasks, reducing labor needs, and optimizing shipping carrier choices. For instance, Kookaburra implemented Sure Sort automation, which led to a 65% reduction in labor dependency and boosted sorting speeds to 2,400 items per hour. The result? A 470% drop in total costs per order.

Automation also significantly improves accuracy, which helps avoid costly mistakes. Barcode scanning, for example, reduces error rates from 1%–4% (each error costing around $75.00) to an impressive 1 in 2.8 million. Take Taste of Texas as an example: after adopting Ordoro's automation tools, they experienced a 15% decrease in fulfillment errors, supporting their 250% compounded annual growth rate.

Another advantage is scalability. Automated systems can handle large order spikes without requiring additional staff. During Black Friday, NPFulfillment managed to scale from 12,000 to 40,000 orders using Sure Sort's iBOT robotic technology - all without hiring extra employees. This flexibility gives 3PLs a competitive edge during peak seasons. McKinsey emphasizes this point, stating that "automation in warehousing is no longer just nice to have but an imperative for sustainable growth". These efficiency gains pave the way for a clear comparison between manual and automated workflows.

Manual vs. Automated Processes

Here's how manual and automated processes stack up:

| Metric | Manual Process | Automated Process |

|---|---|---|

| Cost per Order | $30.00 – $60.00 | $5.00 – $10.00 |

| Processing Time | 8 – 12 hours | 15 – 30 minutes |

| Error Rate | 1% – 4% | ~0.00003% (with barcode scanning) |

| Inventory Accuracy | ~63% | Near 100% real-time visibility |

| Scalability | Requires proportional hiring | Handles spikes with existing staff |

| ROI Timeline | N/A | Payback under 12 months |

These metrics underscore how automation revolutionizes 3PL order processing, making automated systems a must-have for companies looking to stay competitive in a fast-paced market.

sbb-itb-eb0f906

Connecting Automation Tools with Existing Systems

Integrating automation tools into your current setup requires careful planning and execution. When done right, this connection ensures a smooth flow of data, from order capture to fulfillment, amplifying the efficiency gains discussed earlier. Lisa Schwarz, Senior Director of Global Product Marketing at NetSuite, sums it up well:

"Think of an automated order processing system as the central nervous system of your order fulfillment operations".

Despite the fact that 94% of 3PLs offer EDI integration and modern WMS platforms can save an average of 161 hours on manual data entry, over half of companies (55%) still rely on manual processes for managing omnichannel logistics due to outdated systems.

System Integration Best Practices

Before diving into integration, start with a technical discovery phase. Map out your existing data flows, pinpoint any gaps, and assess how different systems interact. This step helps avoid unexpected costs - many integration projects go over budget because of unplanned customizations and ongoing maintenance needs.

Using industry-standard formats like EDI (e.g., ANSI X12 or EDIFACT) and middleware can simplify the process. Middleware helps unify data schemas, reducing the risk of errors and inventory mismatches.

Security is another critical factor. With 33% of logistics organizations identifying cybersecurity as their biggest challenge when adopting new technology, it's essential to implement end-to-end encryption and multi-factor authentication. Nagendra Rao, President of Sales at Trigent Software, highlights the urgency of adopting modern technology:

"AI, automation, and ecosystem connectivity are no longer optional - they're essential for companies looking to differentiate and thrive in a competitive market".

Here’s a quick breakdown of common integration approaches:

| Integration Type | Best For | Key Advantage | Main Challenge |

|---|---|---|---|

| Partner Plugin | Standard SKUs, fast launch | Quick setup, pre-configured | Limited customization options |

| Middleware/OMS | Multi-channel, multi-warehouse | Centralized routing, validated data | Extra layer to maintain |

| Custom API | Complex workflows, unique needs | Ultimate flexibility and control | Requires strong engineering resources |

It’s also important to define clear KPIs from the start. Metrics like order accuracy, inventory variance, fulfillment speed, and system uptime can help measure integration success. To prevent overselling during peak times, set SKU-specific safety stock buffers, and establish a single "source of truth" for inventory to avoid synchronization issues.

Once a robust integration is in place, advanced AI tools can take operations to the next level by enhancing exception handling and overall efficiency.

AI Features for Exception Handling

With seamless integration as a foundation, AI tools can step in to handle exceptions, ensuring consistent performance. Acting as early-warning systems, they detect issues like potential fraud, suspicious order patterns, or inventory discrepancies in real time. Instead of reacting after problems arise, AI enables proactive planning by identifying subtle trends in customer behavior or market conditions.

AI also excels in demand forecasting. By analyzing historical sales data and market trends, it predicts future inventory needs, helping businesses avoid both stockouts and overstocking. This becomes especially important during peak seasons, as 88% of carriers now prioritize AI-powered fleet optimization and route planning for greater efficiency.

Beyond forecasting, AI automates complex logistics decisions. For instance, it can route fragile items to specific warehouses or assign carriers based on order value using preset triggers. In compliance-heavy industries, AI can even auto-generate required documentation for hazardous goods like batteries or aerosols by matching SKU tags to compliant carrier services.

Looking ahead, the integration of humanoid robots is on the horizon, with 72% of executives expecting large-scale deployment within the next five years to handle tasks like sorting and managing delicate items. The logistics automation market reflects this shift, projected to grow from over $88 billion in 2025 to nearly $213 billion by 2032. As one industry analysis puts it:

"The deeper the integration - that is, the more thorough the act of connecting systems, automating processes, and syncing data in real time - the greater the benefits".

Examples of 3PL Automation in Action

Automation Success Stories

These examples show how automation is reshaping 3PL operations, turning complex, time-consuming tasks into seamless, efficient processes. Take Barrett Distribution Centers, for example. In September 2024, at its Hillsborough, N.J., facility, Barrett introduced Gather AI drones to streamline inventory management for their client, Stadium Goods. These drones scan unique license plate barcodes on cases stored in narrow aisle racks, managing an impressive 500,000 pairs of shoes with 99.9% accuracy. Jim Rapoza, Vice President of Business Process Optimization at Barrett, shared:

"The more accurate your inventory is, the more productive you can be - because you don't have unexpected shortages - so you can just pick orders instead of searching for inventory".

The cost savings were equally striking. Manual inventory counting cost about $1.50 per scan, while the drones brought that down to just $0.10–$0.20 per scan. Barrett also incorporated CMC Packaging Automation to create custom-sized boxes for single-line orders, cutting shipping expenses and reducing manual packing demands.

Another standout example is YQN Warehouse 2.0, which achieved remarkable efficiency gains in May 2025. By adopting an automated carousel picking system and high-speed put wall sorting, the facility now processes 3,000 orders per hour with 99.9% accuracy. Their advanced last-mile routing algorithms improved estimated delivery times by 25%, ensuring all orders ship within 24 hours.

Automation also proves invaluable during peak periods. For instance, during a Black Friday surge, NPFulfillment managed to scale operations from 12,000 to 40,000 orders without additional staff. They achieved this by using OPEX Sure Sort iBOT robotic technology, maintaining their same-day shipping promise. Similarly, Kookaburra utilized Sure Sort to handle high-volume sorting, processing 2,400 items per hour while reducing labor reliance by 65%, resulting in a staggering 470% cost reduction per order.

ShipMonk offers another compelling example of automation at scale. Using Locus Robots (AMRs) capable of carrying up to four totes, the company supports human pickers with optimized paths. Combined with their proprietary warehouse management system and pick-to-light technology, ShipMonk processes over 100,000 orders daily with exceptional accuracy. Their clients, including brands like Dr. Squatch and 4Ocean, benefit from this seamless integration of technology. As ShipMonk puts it:

"Ultimately, that's the point of all this automation, robotics, machinery, and integrated technology - to keep your customers happy".

These examples clearly highlight how automation enhances speed, accuracy, and cost-effectiveness in 3PL operations. For e-commerce businesses eager to take advantage of these advanced technologies, platforms like Forthmatch can help connect them with trusted providers.

Conclusion: What's Next for 3PL Automation

Warehouse automation is on a rapid rise, growing over 10% annually, with robot shipments expected to increase by 50% by 2030. But this isn't just about swapping out manual labor for machines - it's about fundamentally changing how orders are processed, from the second a customer hits "buy" to the moment their package lands on their doorstep.

This surge in automation is driving forward a new era of technology. Imagine humanoid robots that can carefully handle fragile items, reshaping warehouse workflows. AI-powered predictive analytics are stepping in to anticipate and prevent bottlenecks, while swarm robotics allow fleets of autonomous robots to work together seamlessly. Add to this inventory-scanning drones, IoT sensors providing real-time stock updates, and even 3D printing for producing spare parts on demand - and the picture of a next-generation warehouse becomes clear.

For e-commerce businesses, choosing the right 3PL partner has never been more critical. With 90% of Fortune 500 companies already outsourcing logistics and 84% of 3PLs utilizing Warehouse Management Systems, the bar for fulfillment standards keeps rising. Tools like Forthmatch make it easier for merchants to evaluate and compare 3PL providers based on their automation capabilities and system integrations - without hidden fees or intermediaries getting in the way.

Automation isn't just a trend; it's a necessity for staying competitive and growing sustainably. Whether you're handling a modest 100 orders a day or scaling up to 100,000, teaming up with a tech-forward 3PL that embraces robotics, AI, and integrated systems could be the difference between thriving and falling behind.

The future of order fulfillment is already here, and it's evolving at breakneck speed.

FAQs

How do 3PLs use automation to streamline order processing?

Third-party logistics (3PL) providers are stepping up their game by integrating automation into their operations. They achieve this by linking warehouse management systems (WMS), enterprise resource planning (ERP) tools, and e-commerce platforms using APIs and middleware. This seamless connection enables real-time data sharing, which powers automated tasks like picking, packing, dimensioning, and label printing - eliminating the need for manual intervention.

Many 3PLs also rely on pre-built connectors for popular platforms like Shopify, Amazon, and Magento. These connectors streamline processes such as order routing, inventory tracking, and shipping updates, making operations more efficient. By incorporating robotics, AI-powered sorting, and real-time analytics into these workflows, 3PLs can achieve faster and more precise order fulfillment.

For direct-to-consumer brands, tools like Forthmatch simplify the search for 3PL partners that specialize in automation. These tools provide insights into technology compatibility, delivery networks, and feedback from other merchants, helping brands make informed decisions.

What are the main advantages of using automation in 3PL order processing?

Automation in third-party logistics (3PL) order processing brings a range of advantages that can transform how businesses handle their operations. For starters, it cuts down processing times, enabling quicker fulfillment and delivery, which keeps customers happy and loyal.

By reducing manual involvement, automation also boosts order accuracy, minimizing mistakes that might otherwise lead to expensive returns or shipping delays.

Another major perk is real-time inventory visibility. Automation allows businesses to track stock levels instantly and make better use of warehouse space. This not only trims operational costs but also streamlines overall efficiency. For businesses and customers alike, the result is a smoother, more dependable experience that builds trust and satisfaction.

How do 3PLs use automation to manage order surges during peak seasons?

Automation has become a game-changer for 3PLs when it comes to handling sudden order surges during holidays, major sales, or other peak seasons. By streamlining workflows, it helps maintain efficiency even under pressure. AI-powered tools play a key role here - they analyze historical data, website traffic trends, and promotional calendars to forecast demand spikes. This allows 3PLs to plan ahead, adjusting staffing levels and strategically positioning inventory to meet the increased demand.

Robotic systems, like automated pickers and guided vehicles, further enhance operations by efficiently managing high-volume areas. These systems ensure that orders are picked, packed, and shipped without a hitch, even when demand skyrockets - sometimes doubling or tripling.

One of the standout benefits of automation is its ability to react in real time, delivering exceptional accuracy that often exceeds 99.9%. It also helps cut labor costs significantly. For direct-to-consumer (DTC) brands, working with 3PLs equipped with advanced automation ensures smooth order fulfillment during the busiest periods. This means deliveries stay on schedule, and expenses remain manageable. Platforms like Forthmatch simplify the process by connecting businesses with pre-vetted 3PLs that utilize these cutting-edge technologies.