Choosing the right third-party logistics (3PL) provider is critical for direct-to-consumer (DTC) brands. A good 3PL can handle fulfillment, shipping, and inventory efficiently, helping your business grow. But the wrong partner can lead to slow deliveries, errors, and hidden fees. To avoid costly mistakes, here are the 10 key questions you need to ask before committing to a 3PL:

- What is your experience with DTC brands? Look for expertise in small orders, multi-channel sales, and seasonal demand.

- Can you scale with my business growth? Ensure they can handle volume spikes and expansion into new markets.

- How does your technology integrate with my systems? Check for seamless compatibility with your e-commerce platforms.

- What is your geographic coverage and delivery performance? Verify warehouse locations, delivery times, and accuracy rates.

- How do you structure your pricing? Ask for transparent cost breakdowns to avoid hidden fees.

- What additional services do you offer? Explore options like custom packaging, kitting, or returns management.

- How do you handle communication and accountability? Ensure they provide a dedicated contact and clear issue resolution processes.

- What are your compliance and risk management practices? Confirm certifications, security protocols, and disaster recovery plans.

- How do you track and report performance? Look for real-time dashboards and detailed KPI tracking.

- Can you provide references and proof of reliability? Speak with current clients and assess their financial stability.

3PL Essentials - Third Party Logistics - 7 Things to LOOK For

1. What Is Your Experience with DTC Brands?

DTC (direct-to-consumer) fulfillment is a whole different ballgame compared to B2B logistics. To avoid costly errors and unhappy customers, you need a 3PL (third-party logistics provider) that knows the ins and outs of this specific type of fulfillment.

Experience with DTC Brands

A 3PL with real DTC experience is a must. Unlike B2B providers that focus on bulk shipments, DTC-focused 3PLs specialize in picking and packing smaller orders. They also understand the unique challenges of managing multi-channel orders across platforms like Shopify, Amazon, and more.

Ask for case studies or references from brands similar to yours. You want a provider who knows how to handle seasonal spikes and the unpredictable growth that often comes with DTC brands. Testimonials and real-world examples can give you insight into how they’ve helped other businesses navigate these challenges.

Take it a step further - reach out to their current DTC clients. Ask about their experiences with order accuracy, shipping speed, and how well the 3PL dealt with busy seasons or promotional rushes. The best DTC brands treat their 3PL as a partner, so look for providers who share that collaborative mindset.

Also, check if they can consolidate orders from multiple sales channels while keeping inventory accurate across the board. This capability is critical for smooth operations.

Handling Product-Specific Challenges

Beyond general DTC expertise, it’s crucial to confirm that a 3PL can handle your specific product type. For example:

- If you sell perishable goods, find out if they have experience with strict tracking requirements and proper storage conditions for food.

- For fragile or high-value items, ask about their quality control measures and whether they use warehouse systems that can track individual SKUs with precision.

Request detailed information about their storage capabilities, handling procedures, and any relevant certifications. Case studies showcasing how they’ve successfully managed similar product types can also be incredibly helpful. Don’t forget to ask about their error rates and how they prevent damages during storage and shipping.

Some 3PLs even offer virtual bundling, which allows them to assemble product bundles in real time rather than pre-assembling them. This can save time and reduce inventory complexity.

If you’re unsure where to start, platforms like Forthmatch can simplify your search. This free global directory of vetted 3PL providers is specifically tailored for DTC brands. It lets you compare fulfillment partners based on delivery reach, platform compatibility, and feedback from other DTC merchants.

Ultimately, the goal is to find a 3PL that doesn’t just claim to understand DTC fulfillment but can back it up with proven results, satisfied clients, and the specialized skills your business needs. Once you’ve confirmed their expertise, the next step is evaluating whether they can scale alongside your growth.

2. Can You Scale with My Business Growth?

Your business is bound to grow, and your fulfillment needs must grow with it. Choosing the wrong third-party logistics (3PL) provider can hold you back, while the right one becomes a true partner in helping you scale efficiently. Before signing on with any provider, it’s crucial to understand how they’ll support your expansion plans.

Capacity for Growth

One key question to ask is: "How do you handle fluctuations in order volume, such as seasonal peaks or sudden sales surges, without compromising delivery timelines or quality?" This isn’t just about having extra space in a warehouse - it’s about having the right systems and processes in place to adapt quickly to your changing needs.

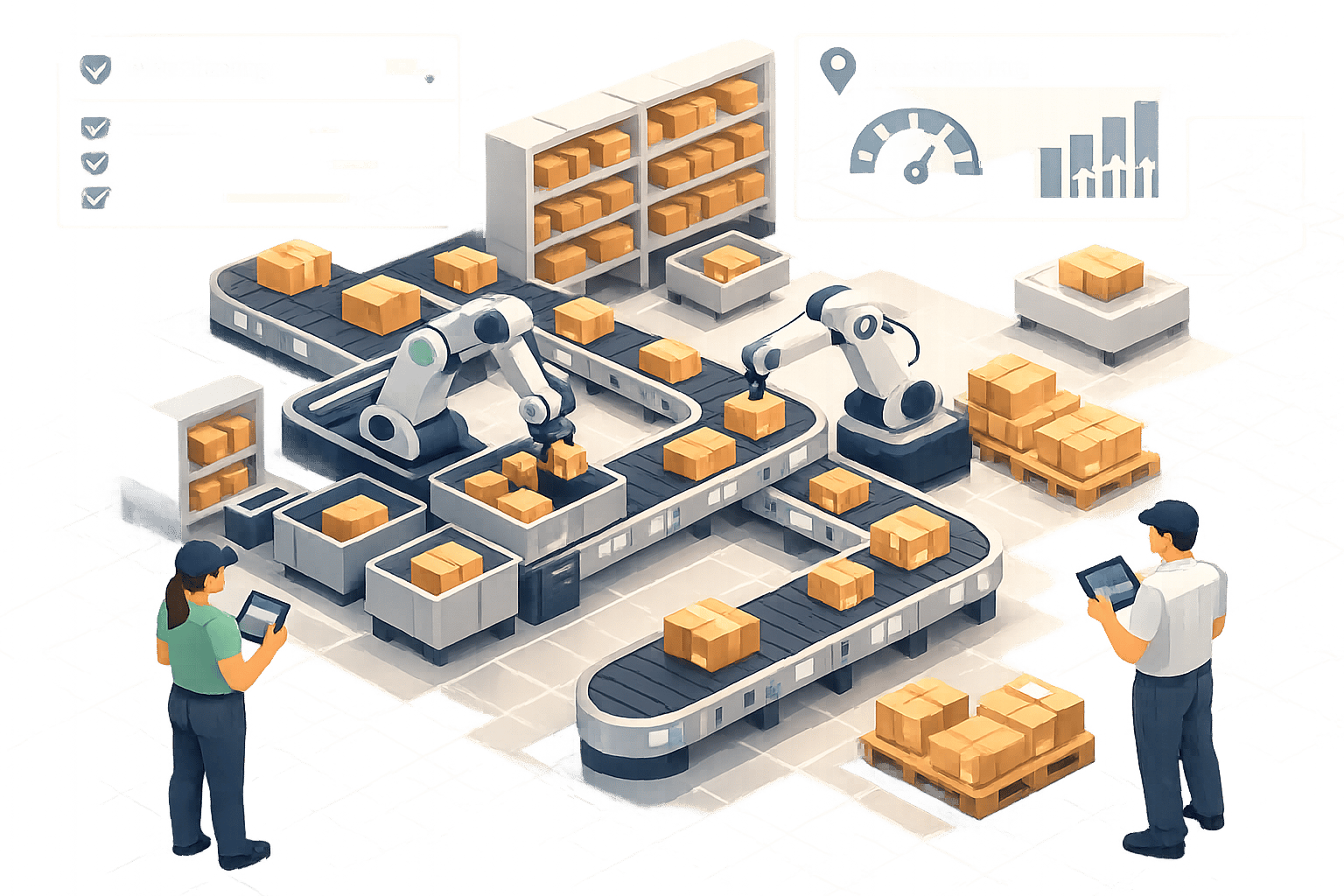

A dependable 3PL should be able to scale operations seamlessly, so you don’t have to worry about forecasting additional capacity or scrambling to hire temporary staff. They should use advanced warehouse management systems to track individual SKUs, ensure inventory accuracy during high-volume periods, and optimize pick lines while maintaining quality control.

Ask for real-world examples of how they’ve supported other direct-to-consumer (DTC) brands during periods of rapid growth. The strongest 3PLs can help businesses scale from seven to eight or even nine figures in revenue without sacrificing service quality. Look for providers that offer flexible storage solutions, temporary warehousing, and overflow fulfillment capacity to handle unexpected demand spikes.

It’s also smart to request historical performance data. Reliable partners will have metrics that demonstrate their ability to maintain low error rates and on-time delivery, even during their busiest times. They should also be equipped to combine orders, adjust inventory allocations, and manage backorders on short notice. Features like real-time dashboards, replenishment alerts, and adaptable workflows can help you manage inventory efficiently and avoid stockouts. But scaling isn’t just about handling more orders - it’s also about staying agile in a constantly evolving market.

Support for Market Changes

Growth often means more than just higher order volumes. It might involve entering new sales channels, launching products, or expanding into new regions. A good 3PL should be able to support these initiatives without requiring a complete operational overhaul.

Geographic expansion, for instance, can be tricky. As your customer base grows, delivering quickly and consistently across different regions gets harder if you’re relying on a single warehouse. Look for providers with strategically located fulfillment centers that can handle zone-based shipping. This reduces last-mile delivery costs while ensuring consistent delivery times for customers in various locations.

If international expansion is on your radar, confirm that the 3PL offers global solutions and can serve key markets efficiently. They should also be able to handle unique needs, like virtual bundling, custom packaging, or managing returns, with ease.

Technology is another critical factor. The 3PL’s systems should integrate seamlessly with your e-commerce platforms and new sales channels through open APIs. They should give you complete visibility into your inventory across the supply chain and provide tools that are easy for your team to use when making changes or pulling reports.

Don’t overlook financial stability. Ask how long the provider has been in business and whether they’re equipped to handle your long-term growth. Positive reviews and testimonials from other DTC brands at different growth stages can provide valuable insights. It’s also worth asking about their disaster recovery plans and experience dealing with supply chain disruptions.

The best 3PLs act as more than just a service provider - they become a strategic extension of your business. They take the time to understand your goals and adapt their services to meet your needs. When assessing scalability, look for transparency. A strong partner will provide access to key performance indicators and automated reports, showing how their operations grow alongside yours.

3. How Does Your Technology Integrate with My Systems?

When it comes to operational efficiency, having technology that integrates smoothly with your existing systems is just as important as scalability. A poorly integrated setup can lead to errors and headaches, while a well-implemented system can keep your operations running like clockwork. Let’s break down how inventory management, e-commerce compatibility, and user usability play a key role in successful integration.

Before choosing any 3PL provider, make sure you understand how their technology will connect with your systems. It’s not just about linking to your e-commerce platform - it’s about creating a cohesive network that supports both your day-to-day needs and your long-term goals.

Inventory and Order Management Systems

For DTC brands, having real-time visibility into your inventory isn’t optional - it’s essential. Ask potential 3PL providers, "What inventory and order management systems do you use, and how do they handle real-time tracking and analytics?" Their response should highlight the capabilities of their warehouse management system (WMS).

The best 3PLs provide tools like real-time SKU tracking, low-stock alerts, and analytics to help with demand forecasting. Your dashboard should offer a clear view of stock levels, warehouse locations, and reorder notifications. According to industry data, 3PLs with real-time inventory tracking and automated order fulfillment can reduce errors by up to 30% and improve delivery times by 20%. Look for features like customizable reporting and multi-warehouse tracking. Don’t forget to request a live demo so you can see their dashboard in action and review sample reports.

E-Commerce Platform Compatibility

If you’re looking to scale your operations without running into errors, seamless integration with your e-commerce platform is a must. A survey by EP Logistics revealed that 78% of DTC brands consider technology integration a top priority when selecting a 3PL partner. Ask directly, "How does your technology integrate with my specific e-commerce platform, and what does the setup process involve?" Whether you use Shopify, WooCommerce, Magento, or another platform, the integration should automatically sync orders, inventory, and tracking data via APIs or apps.

For businesses operating across multiple sales channels, check if the 3PL’s system consolidates orders and inventory into a single dashboard. This unified view helps prevent issues like overselling and ensures consistent reporting across platforms.

Also, discuss the onboarding timeline. A capable 3PL should be able to complete integrations within a few days to a couple of weeks. Look for providers that offer dedicated onboarding specialists and clear documentation to speed up the process.

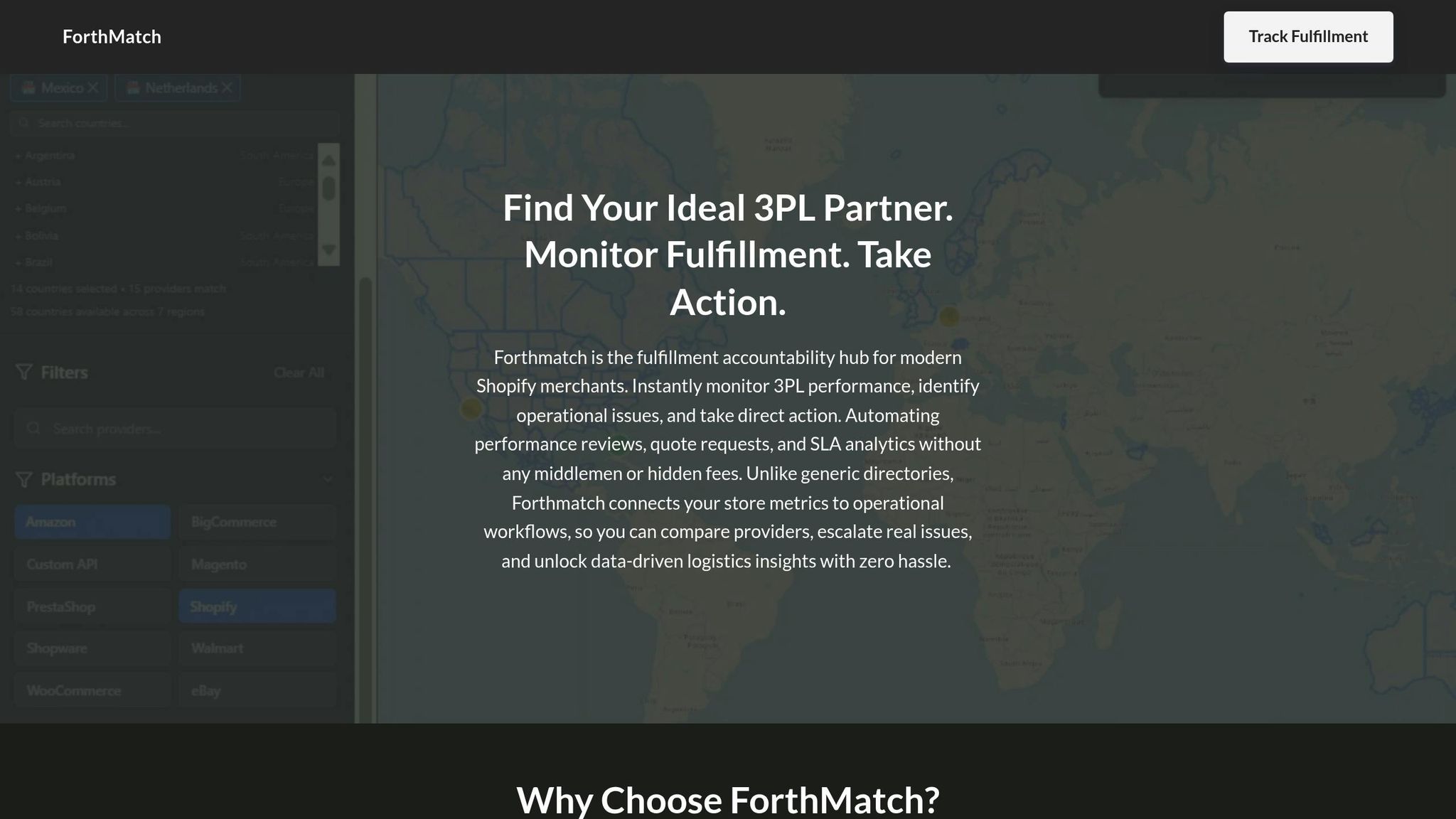

"Forthmatch gave us daily, granular visibility into fulfillment delays and real accountability with our 3PL partner. The before/after tracking saved us $600/month and gave us a clear action plan to improve operations."

– Gordon Belch, Co-Founder at vybey

Client-Facing Usability

Even the most advanced systems won’t help if they’re difficult to use. That’s why it’s crucial to evaluate the user-friendliness of the 3PL’s client portal or dashboard. Request a hands-on demo to get a feel for its functionality.

Top 3PLs offer intuitive, web-based dashboards that allow you to monitor inventory levels, track shipments, generate reports, and manage returns - all without needing advanced technical skills. Mobile access is another key feature; your team should be able to check metrics and address issues on the go. Look for tools like customizable reports and real-time notifications for order updates and inventory changes.

Don’t overlook the quality of technical support either. Ask about their support options: Do they provide live chat, phone, or email assistance? How quickly do they respond to issues? Reliable 3PLs will have dedicated technical support teams and clear escalation procedures for handling system downtime or integration problems.

Lastly, ensure the 3PL follows industry-standard security protocols to protect sensitive data. This includes measures like data encryption, secure user authentication, and regular system audits to maintain trust and safeguard customer information.

Platforms like Forthmatch can help you compare 3PL technology capabilities more efficiently, giving you a clearer picture of what each provider offers.

4. What Is Your Geographic Coverage and Delivery Performance?

Geographic coverage and delivery performance are critical to ensuring your customers receive their orders on time and without hassle. A reliable 3PL partner not only scales with your business but also supports efficient deliveries through a well-structured geographic network. Factors like warehouse locations, shipping zones, and delivery metrics directly influence your brand's ability to meet customer expectations.

Before signing on with a 3PL, it’s essential to verify their coverage areas and track record. Dive into their warehouse network to ensure it aligns with where your customers are located.

Warehouse Locations and Shipping Zones

It’s not just about how many warehouses a 3PL operates - it’s about where they’re located. Strategic positioning of warehouses can significantly cut down on transit times and shipping costs. A good question to ask potential partners is: "How many warehouses do you have, and where are they located across the U.S.?"

For example, a 3PL with facilities in Los Angeles, Dallas, and New Jersey can offer 2-day ground shipping to most U.S. addresses. This multi-node setup can reduce delivery times by up to 40% compared to relying on a single warehouse. In fact, 70% of DTC brands in a 2023 survey identified geographic coverage as a top priority when choosing a 3PL partner.

Ask for a map of their warehouse locations and an explanation of how they manage shipping zones. Shipping zones are determined by the distance between the fulfillment center and the delivery address. Orders that cross more zones cost more and take longer to arrive. A 3PL with a broad network can assign orders to the closest facility, keeping costs low and delivery times short.

You’ll also want to see historical performance data: "What percentage of U.S. orders can you deliver within 1-2 business days? What are the typical delivery times for regions like the Northeast, Midwest, and West Coast?" Top-tier 3PLs often provide benchmarks like "95% of orders delivered within 2 days to the continental U.S."

For remote areas, ask: "How do you handle shipping to hard-to-reach locations, and what additional costs or delays should I expect?" This helps you plan for potential challenges and manage customer expectations.

Delivery Accuracy and SLA Metrics

Performance metrics reveal a 3PL’s true capabilities. Ask directly: "What are your delivery accuracy and on-time delivery rates, and how do you measure these?" Leading U.S. 3PLs often report on-time delivery rates of 97% or higher and order accuracy rates above 99%. Request data from the past 12 months to evaluate their consistency.

Delivery accuracy measures whether the correct items are shipped to the correct addresses on time. On-time delivery rates track how often orders arrive within the promised timeframe. Both metrics are critical for maintaining customer satisfaction and protecting your brand’s reputation.

Service Level Agreements (SLAs) are essential for accountability. Ask for SLA documents that outline expectations for delivery accuracy, on-time rates, and remedies for missed targets, such as fee credits for late shipments. This ensures both parties are aligned from the start.

Peak seasons and unexpected disruptions test a 3PL’s resilience. Ask for specific examples: "How do you manage high-volume periods or disruptions like severe weather or carrier delays?" Look for evidence of contingency plans, such as rerouting orders to other warehouses or using backup carriers. A strong 3PL will have strategies in place and examples of how they’ve successfully navigated challenges in the past.

To further validate their claims, request references or case studies from similar DTC brands. Look for examples of improved delivery times, lower shipping costs, or high customer satisfaction. If possible, speak directly with their clients to get unfiltered feedback.

Tools like Forthmatch provide real-time maps and merchant feedback to compare 3PL warehouse coverage and delivery metrics. This transparency allows you to make informed decisions based on solid data rather than sales pitches.

Lastly, assess their ability to adapt: "How often do you review and improve your warehouse network and carrier partnerships?" The logistics industry changes quickly, and your 3PL should demonstrate a commitment to staying ahead through network optimizations, new facilities, or technology upgrades.

5. How Do You Structure Your Pricing?

Having a clear and transparent pricing structure is critical. Hidden fees can eat into your profits and make financial planning a headache. Just like scalability and technology, straightforward pricing is a cornerstone of a successful logistics partnership for your DTC brand.

A good starting point is to ask: "What are the main components of your pricing structure?" This can help you separate providers with transparent costs from those who might hide fees in vague estimates.

Itemized Cost Breakdown

A reliable 3PL pricing model should break down costs into clear categories. These typically include:

- Storage fees: Charged per pallet, bin, or cubic foot.

- Pick-and-pack costs: Based on order or item.

- Shipping rates: Determined by carrier, zone, or weight.

- Receiving fees: For incoming inventory.

- Packaging materials: Costs for boxes, tape, or custom packaging.

- Additional surcharges: Fees for oversized items or special handling tasks.

Storage Fees

Storage costs usually depend on how much space your inventory takes up. It’s worth asking: "How are storage fees calculated? Are there different rates for short-term versus long-term storage?" Some providers may offer discounts for long-term storage but charge higher fees for inventory that sits unsold for too long. Knowing these details can help you plan your budget more effectively.

Pick-and-Pack Fees

These fees cover the labor involved in retrieving and packing items for shipment. Be sure to ask: "What’s included in your pick-and-pack fees? Are there extra charges for multi-item orders or special packaging?" Understanding these details will give you a clearer picture of your true per-order costs.

Shipping Rates

Shipping costs are another key factor. Ask: "How are shipping rates determined? Do you offer discounted carrier rates or zone-based pricing?" Many 3PLs negotiate bulk discounts with carriers and pass those savings to their clients. Some also use multiple warehouse locations to reduce last-mile delivery costs, which can speed up delivery times for your customers.

Onboarding and Integration Fees

Some 3PLs charge one-time fees for setting up your account, integrating systems, or onboarding your team. This might include connecting your e-commerce platform or configuring inventory management tools. Knowing these costs upfront will help you plan for the transition.

Volume Discounts

Ask about incentives for higher order volumes. Many 3PLs offer tiered pricing or volume discounts as your business grows. These might include lower pick-and-pack fees, reduced storage costs, or shipping rebates. Understanding the thresholds for these discounts can help you align your fulfillment costs with your growth goals.

Clear Pricing Practices

Transparency isn’t just about listing fees - it’s about ensuring predictable costs and clear communication. A good question to ask is: "Can you share examples of hidden or unexpected fees other clients have faced? How do you ensure pricing transparency?" Hidden fees can show up as charges for inventory audits, minimum monthly orders, or penalties for non-compliance with labeling. Leading 3PLs address these issues by offering clearly defined contracts and routine billing audits.

Pricing Reviews and Updates

Ask how often pricing is reviewed and how updates are communicated. Reputable 3PLs typically provide advance notice of changes, especially when they’re tied to fluctuations in carrier rates or labor costs. Clear documentation of these updates is a sign of a reliable partner.

Direct Billing Details

To avoid hidden markups, request itemized billing. This ensures you’re only paying for what you’ve agreed upon.

Sample Invoices

Ask for a sample invoice or case study. Reviewing these can help you understand how fees are applied - from storage to shipping - and identify areas to optimize costs.

Seasonal Costs

Be mindful of variable costs like peak season surcharges or minimum order requirements. These can sneak up on you if they’re not disclosed upfront.

Forthmatch simplifies pricing comparisons by providing real merchant feedback and direct access to providers. Their "Request Quotes" service, priced at $50 per session, helps you launch campaigns with multiple 3PLs, track responses, and choose the best partner for your needs - all while cutting out brokers and hidden fees for greater clarity.

sbb-itb-eb0f906

6. What Additional Services Do You Offer?

A 3PL's extra services can elevate the customer experience and strengthen your brand. These offerings can transform a basic fulfillment setup into a partnership aimed at helping your business grow.

One key question to ask is: "What additional services do you provide, and how do they fit into my current operations?" This can help you identify not just the services available, but how well they integrate with your existing processes. It's also worth evaluating how these services can enhance your brand's presentation.

Custom Packaging and Branding

Packaging plays a huge role in reinforcing your brand identity. A well-equipped 3PL can create memorable unboxing experiences that leave a lasting impression on customers.

Branded Packaging Options

Many 3PLs now offer packaging solutions that go beyond the standard brown box. Think custom boxes featuring your logo and colors, inserts that highlight your products, or personalized packing slips with thank-you notes. Be sure to ask for examples, details about the setup process, and expected timelines for implementation.

Sustainable Packaging Choices

Eco-conscious packaging is becoming increasingly popular. Options like recycled cardboard and compostable mailers are often available. If sustainability is part of your brand values, inquire about costs and how these options compare to traditional materials.

Kitting and Assembly Services

Some advanced 3PLs use warehouse management systems to handle kitting and bundling on demand. This means you can experiment with new product combinations without pre-assembling inventory, saving on storage costs and supporting dynamic marketing campaigns.

Customization Capabilities

Certain providers can also include extras like promotional materials, product samples, or seasonal inserts in your orders. These small touches can boost customer engagement and encourage repeat purchases.

In fact, a 2023 survey found that 72% of DTC brands working with 3PLs offering extras like custom packaging and branded inserts saw higher repeat purchase rates compared to those using basic fulfillment services.

These services highlight the difference between a 3PL acting as a true partner versus just a service provider. Beyond packaging, an efficient returns process is another critical factor for customer satisfaction.

Returns Management

A hassle-free returns process can turn a one-time buyer into a loyal customer. With over 60% of U.S. online shoppers citing the returns process as a key part of their purchase decision, having a strong returns system is essential for DTC brands.

Returns Processing Workflow

Look for a 3PL that offers automated returns authorization, product inspection, and restocking, all with real-time tracking. Ask questions like: "How quickly do you process returns? How are damaged or defective items handled?"

Customer-Friendly Returns Portals and Analytics

Some 3PLs provide branded portals where customers can initiate returns, print prepaid labels, and track their return status. Top providers also offer dashboards with insights into return rates, reasons for returns, and processing times. These analytics can help you pinpoint product issues or packaging tweaks to reduce future returns.

Return Inspection and Restocking

Quality control matters when it comes to returns. Leading 3PLs use detailed inspection protocols and barcode scanning to decide which items can be restocked, ensuring inventory accuracy.

Integration with E-commerce Platforms

Modern 3PLs often integrate with platforms like Shopify, Magento, and WooCommerce, syncing return details automatically. This keeps inventory levels accurate, avoids overselling, and ensures smooth communication with customers.

When evaluating a 3PL's returns capabilities, ask for specific examples or case studies showing how they've helped brands improve their returns processes. Learning about their experience with businesses similar to yours can provide reassurance that they'll meet your needs effectively.

Forthmatch can help you compare 3PL providers based on these additional services, offering real merchant feedback on areas like custom packaging, kitting, and returns management.

7. How Do You Handle Communication and Accountability?

Strong communication and accountability are the backbone of any successful 3PL partnership. You need a reliable point of contact to keep you updated on order status, inventory levels, and any operational hiccups - while also addressing problems quickly. Clear communication ensures smooth logistics operations, which are essential for sustaining your business.

Point of Contact and Responsiveness

A dedicated account manager can make all the difference in your day-to-day operations. This person should be well-versed in your business needs, understand your busy seasons, and act quickly when challenges arise.

Dedicated Account Management

Ask potential 3PL providers: "Who will be my go-to contact, and how involved will they be in daily communication?" The best 3PLs assign a single account manager or client success representative to handle your account. This person will take care of routine inquiries, escalate urgent issues, and ensure everything stays on track.

Your account manager should be easy to reach via phone and email during standard U.S. business hours. During high-pressure times like Black Friday or the holiday season, having someone who knows your priorities can stop minor issues from snowballing into major disruptions.

Response Time and Escalation

Set clear expectations for response times. Your provider should commit to replying within two business hours and resolving critical issues within 24 hours. Make sure they also have a clear escalation process for unresolved matters, allowing you to reach senior operations staff if needed.

Don’t just take their word for it - test their responsiveness during the evaluation phase. Observe how quickly they answer your questions and how thoroughly they address your concerns. This will give you a realistic sense of what working with them will be like.

Issue Management Process

When problems occur, you need to know immediately - before your customers do. A proactive 3PL will have systems in place to identify issues early and communicate them clearly.

Proactive Notification Systems

The best 3PLs use automated systems integrated with their warehouse management software to flag issues like shipment delays, inventory mismatches, or service interruptions. For example, automated alerts can notify you of a delayed shipment, giving you time to inform your customers and manage expectations.

Structured Problem Resolution

Ask potential providers: "How do you handle problems like lost shipments or delivery errors?" Top-tier 3PLs follow a structured process that includes a thorough investigation, root cause analysis, and a documented resolution plan. They’ll keep you updated throughout the process and provide a final report explaining what went wrong, how it was fixed, and steps to prevent similar issues in the future.

Accountability Measures

A reliable 3PL backs its promises with concrete accountability measures. These might include performance-based SLAs (Service Level Agreements), financial penalties for missed targets, and transparent error reporting. Some providers even offer service credits or refunds if they fail to meet agreed-upon standards. For example, if your 3PL commits to a 99% on-time shipping rate but falls short, they should compensate you with partial refunds or credits for future services. Ensure these measures are clearly detailed in your contract.

Use of Tools Like Forthmatch

Modern technology can take communication and accountability to the next level. Platforms like Forthmatch provide tools and visibility that help you monitor performance and hold your 3PL accountable.

Real-Time Performance Monitoring

Forthmatch allows you to track every order, monitor your provider’s performance, and ensure SLA compliance in real time. You can see the status of inbound, in-process, and shipped orders across all fulfillment centers, making it easier to spot and address issues quickly.

SLA Analytics and Automated Alerts

With Forthmatch, you can analyze service metrics like on-time rates, average processing speeds, and trends in delays. Automated alerts notify you of SLA breaches so you can address problems before they escalate.

Structured Accountability Sessions

For $50 per session, Forthmatch offers formal accountability reviews. These sessions provide a structured way to evaluate performance metrics, discuss areas for improvement, and document commitments to better service.

Direct Communication Channels

Platforms like Forthmatch also give you access to verified performance data, merchant reviews, and direct communication with your 3PL. This transparency ensures your 3PL remains accountable for their service quality, pricing, and delivery standards.

8. What Are Your Compliance and Risk Management Practices?

Supply chain disruptions and data breaches can severely impact your reputation and erode customer trust. A 3PL's approach to compliance and risk management safeguards customer data, ensures smooth operations, and meets regulatory standards. According to a 2023 survey by Resilinc, 73% of companies faced at least one major supply chain disruption in the past year, highlighting the growing need for strong risk management practices.

The logistics sector also reported a 35% increase in data breaches between 2022 and 2023, according to IBM Security. This makes it critical to assess your potential 3PL's security measures and compliance standards before signing any agreements. Below, we’ll explore the certifications, security protocols, and disaster recovery strategies you should prioritize when choosing a 3PL partner.

Certifications and Security Protocols

Certifications demonstrate that a 3PL follows established best practices in security, quality, and data protection. A key question to ask is: "What certifications does your company currently hold, and when were they last renewed?"

Key Certifications to Look For

The following certifications indicate adherence to high standards:

- ISO 27001: Information security management.

- SOC 2 Type II: Ongoing testing of data security controls, particularly crucial for DTC brands managing sensitive customer information.

- PCI DSS: Payment data protection.

- ISO 9001: Quality management systems.

- For regulated products, verify certifications like FDA, HACCP, or DEA, depending on your industry.

SOC 2 Type II compliance stands out because it goes beyond policy reviews (as seen in Type I) by requiring months of testing to ensure security protocols are effective.

Data Protection and Privacy Standards

For brands operating internationally, inquire about compliance with GDPR or similar data protection regulations. Confirm that the 3PL has clear policies for data retention, access, and deletion.

Ask for documentation of certifications and renewal dates. A reliable 3PL will readily share this information and explain how these certifications shape their daily practices.

Disaster Recovery Plans

Unforeseen events like natural disasters, cyberattacks, or supply chain interruptions can bring operations to a standstill. A 3PL’s disaster recovery plan determines how quickly they can bounce back and keep your business running during emergencies.

Geographic Redundancy and Backup Facilities

One critical question to ask is: "How quickly can you reroute orders if your primary facility becomes unavailable?" Leading 3PLs operate geographically distributed fulfillment centers, allowing them to shift operations seamlessly. For example, if a hurricane impacts an East Coast facility, they can reroute orders to the Midwest or the West Coast.

Ensure the 3PL has defined Recovery Time Objectives (RTO). Industry leaders typically aim to resume basic operations within 24–48 hours and full functionality within 72 hours after a disruption.

Technology and Communication Systems

Backup systems are essential. Ask about their backup power sources, redundant internet connections, and alternative communication protocols in case of emergencies.

Carrier Diversification

Shipping delays caused by major carriers like UPS or FedEx can disrupt thousands of orders. A well-prepared 3PL maintains relationships with multiple carriers, both regional and national, to ensure flexibility when one carrier faces issues.

Inventory Protection and Insurance

Verify the 3PL’s cargo insurance coverage and liability limits. If inventory is lost or damaged during a disaster, what is the maximum reimbursement they offer? Request copies of their insurance certificates and confirm that coverage is up-to-date. Financially stable 3PLs generally carry robust general liability insurance to protect high-value inventory.

Testing and Documentation

The best disaster recovery plans aren’t just written - they’re tested. Ask when the 3PL last conducted a disaster recovery drill and what the results were. A dependable provider should share examples of how they’ve successfully navigated past disruptions, proving their ability to execute contingency plans under pressure.

To simplify the vetting process, platforms like Forthmatch allow DTC brands to filter 3PLs based on compliance certifications, security protocols, and risk management practices. This transparency ensures you can identify logistics partners with proven disaster recovery capabilities before finalizing any contracts.

9. How Do You Track and Report Performance?

A trustworthy 3PL should provide clear and reliable performance tracking. Just like system integrations, the ability to monitor and analyze performance is a cornerstone of operational success. For instance, a 2024 study by DCL Logistics revealed that DTC brands leveraging real-time performance data saw their order accuracy climb from 97.5% to 99.3% and reduced late shipments by 40% within six months.

The real question isn't whether your 3PL tracks performance - it’s about how accessible, transparent, and actionable their reporting is. Top-tier 3PLs understand the importance of providing visibility into inventory levels, order statuses, and fulfillment metrics to help brands maintain a competitive edge.

Key Performance Indicators (KPIs)

When evaluating a 3PL, ask: "What specific KPIs do you track, and how do they align with the needs of DTC brands?" The most important metrics for direct-to-consumer fulfillment include:

- Order accuracy rate: The percentage of orders shipped without errors.

- On-time fulfillment rate: Orders shipped within the promised timeframe.

- Inventory accuracy: Ensuring stock levels match what’s reported.

- Order cycle time: The time it takes from order placement to shipment.

- SLA adherence: How well the 3PL meets service level agreements.

Industry benchmarks are critical here. For example, an order accuracy rate above 99% and an on-time shipping rate over 97% are considered top-tier for DTC fulfillment. Leading providers often achieve even higher metrics, such as 99.8% order accuracy and 98% on-time shipping, showcasing their operational strength.

Ask for specific historical data. Request at least 12 months of performance history to ensure consistency. A dependable 3PL should also supply exception reports that highlight delays or problematic orders, demonstrating their ability to identify and resolve issues proactively.

Customization is key. Ensure you can tailor KPIs to focus on what matters most for your business, whether it’s performance by product line, sales channel, or region. Many advanced 3PLs offer customizable reporting tools to give you the insights you need.

Access to Automated Reports

Once you’ve identified the right metrics, assess how easily you can access real-time data. Ask: "Do you provide real-time dashboards or automated reports, and how easy are these tools to use?" Leading 3PLs use advanced systems like warehouse management systems (WMS) and order management systems (OMS) with powerful reporting features. These systems often integrate seamlessly with eCommerce platforms like Shopify or Magento, enabling unified reporting across multiple sales channels.

Dashboards are essential for fast-paced DTC brands. They allow continuous monitoring of KPIs, making it easy to spot trends or address issues as they arise. Some 3PLs even provide automated alerts to notify you of performance dips, such as late shipments or inventory discrepancies.

Top-performing 3PLs don’t just report data - they offer actionable insights. These might include recommendations for inventory adjustments, changes to shipping methods, or workflow improvements to enhance efficiency and customer satisfaction.

"Forthmatch gave us daily, granular visibility into fulfillment delays and real accountability with our 3PL partner. The before/after tracking saved us $600/month and gave us a clear action plan to improve operations."

- Gordon Belch, Co-Founder at vybey

Reliable 3PLs ensure accuracy through automated data capture and regular audits. They should provide direct access to raw data and maintain audit trails to minimize discrepancies or hidden issues.

Finally, confirm that the interface is user-friendly, supports both scheduled and custom reports, and requires minimal training. Look for options to receive scheduled reports (daily, weekly, or monthly) while also being able to generate custom reports on demand.

For brands that want additional oversight, tools like Forthmatch offer independent performance tracking and SLA analytics. These platforms provide an unbiased view of your 3PL’s performance, along with tools for accountability and benchmarking against industry standards.

10. Can You Provide References and Proof of Reliability?

Trust is the backbone of any successful 3PL partnership, and verifying a provider's track record is a crucial step in ensuring they can meet your business needs. As discussed earlier, effective communication and robust technology are key, but you also need to assess their reliability through references and financial stability. This step helps safeguard your business from unexpected disruptions, such as sudden closures or service issues, while ensuring you partner with a provider capable of supporting your long-term goals.

Client References and Testimonials

One of the first things to ask is: "Can you share direct contact information for three current clients with business models similar to mine?" While written testimonials can offer some insight, direct conversations with current clients provide a clearer, more detailed picture of the 3PL's performance.

When reviewing references, focus on relevance. A provider that excels with large-scale enterprise clients may not be the best fit for a direct-to-consumer (DTC) brand requiring smaller order volumes, custom packaging, or specific shipping patterns. Look for references from businesses that align closely with your product categories, order sizes, or seasonal demands.

During these conversations, ask pointed questions about how the provider handles challenges. For example:

- How do they manage peak season demand surges?

- What steps do they take to resolve inventory discrepancies?

- How do they address shipping delays?

These real-world scenarios can reveal how the 3PL operates under pressure and their ability to solve problems effectively.

Consistency across references is another key indicator. If one client raves about excellent communication while another complains about poor responsiveness, it may point to inconsistent service. Cross-checking feedback through independent platforms like Forthmatch can provide additional, unbiased insights. These tools allow you to see feedback from other DTC brands, giving you a more complete understanding of the provider's reputation beyond the handpicked testimonials they share.

Additionally, request case studies that highlight measurable results, such as improved shipping times or reduced error rates. These examples offer concrete evidence of the provider's ability to deliver results for businesses like yours.

Financial Stability and Longevity

The financial health of a 3PL provider plays a significant role in their ability to deliver consistent service, invest in technology, and weather economic challenges. A simple but effective question to ask is: "How long have you been in business, and can you provide evidence of your financial stability?"

Longevity often signals reliability. While newer companies can still be viable, providers with 10 or more years in the industry have typically navigated through various market shifts and refined their operations. They’re more likely to have established strong vendor relationships and developed expertise in handling complex logistics challenges.

Signs of financial stability include regular investments in technology and infrastructure. Ask about recent upgrades to warehouse management systems, expansions in facility space, or new service offerings. These updates indicate a company that is growing and committed to improving its capabilities.

If possible, request details about their credit ratings or financial disclosures. While private companies may not share full financial statements, they should be able to provide general information, such as annual revenue ranges or credit ratings from reputable agencies.

Another useful indicator is client retention rates. High turnover could suggest underlying issues like service quality problems or financial instability. On the other hand, long-term client relationships often point to a stable and reliable provider.

Look for industry certifications and awards as well. Certifications like ISO 9001 for quality management can demonstrate a commitment to maintaining high standards, while awards can highlight operational excellence and reliability.

Be cautious of providers unwilling to share details about their financial health. Transparency in this area is non-negotiable - if a 3PL hesitates to provide this information, it could be a red flag signaling potential risks down the line.

For added assurance, platforms like Forthmatch offer directories of vetted 3PL providers with proven financial stability. These resources can help you avoid risky partnerships and connect with providers that have a track record of success with DTC brands.

Conclusion

Partnering with the right 3PL provider can make or break your logistics operations. The ten questions in this checklist are designed to guide you toward a provider that aligns with your business goals, adapts to your growth, and meets the transparency and reliability standards your customers expect.

This choice isn’t just operational - it’s financial. Rising shipping costs can eat into your margins, and a misaligned 3PL can result in late deliveries, unexpected fees, inventory issues, and strained customer relationships. On the flip side, the right 3PL becomes more than a service provider - they become a seamless extension of your business. They’ll help you improve inventory turnover, cut last-mile delivery expenses, and stay nimble in a shifting market.

Think of selecting a 3PL as forging a strategic partnership. Leading DTC brands work closely with their 3PLs on initiatives like custom packaging, bundling, data integration, and post-purchase automation. Achieving this level of collaboration starts with thorough research - asking the right questions and verifying answers through references, case studies, and clear pricing details.

Focus on measurable results. Instead of getting swayed by sales pitches or vague testimonials, prioritize data like on-time delivery rates, order accuracy, and tech integration. Platforms like Forthmatch simplify this process, offering a curated list of vetted 3PL providers tailored for DTC brands. They cut out brokers and hidden fees while providing real merchant reviews and direct contact options.

But the work doesn’t stop at selection. Keep the partnership strong by setting clear KPIs, maintaining open communication, and regularly reviewing performance to ensure alignment as your business evolves. The questions you ask during the selection process should serve as the foundation for ongoing accountability and continuous improvement.

FAQs

How can I make sure a 3PL can handle my product type, especially if it’s perishable or fragile?

When selecting a 3PL provider, it's crucial to verify they can handle your specific product type. Ask about their experience with similar items and check if they offer facilities like climate-controlled storage for perishables or specialized packaging for fragile goods. Make sure they have the proper certifications and processes to ensure your products are handled safely and efficiently.

It’s also worth considering 3PL providers that focus on your product category. Their expertise often aligns better with the unique logistics requirements of your business.

How can I ensure a 3PL provider is financially stable and reliable for a long-term partnership?

Before partnering with a 3PL provider, it’s important to take a close look at their financial stability and dependability. This helps ensure your supply chain stays on track without unexpected hiccups. Start by reviewing their financial statements or annual reports to get a sense of their stability and growth over time. You’ll also want to dig into their history - how long they’ve been in the business, feedback from clients, and any industry recognition they’ve earned.

To feel more secure in your choice, ask for references from other brands they’ve worked with. It’s also worth discussing how well they can handle changing logistics demands. A reliable 3PL will have a solid track record of keeping promises and growing alongside their partners.

How can I ensure a 3PL's technology integrates smoothly with my e-commerce platforms and supports future growth?

When evaluating a 3PL provider, the first step is to ensure their system works smoothly with your existing platforms - whether that's Shopify, WooCommerce, Amazon, or others. Check if their technology supports essential features like real-time inventory updates, order tracking, and multi-channel fulfillment. It's also important to confirm that their system can handle growth, whether that means scaling up for higher order volumes or integrating new sales channels down the line.

To get a clearer picture, ask for a demo or review case studies that showcase how their tools perform in real-world scenarios. Don’t forget to inquire about their onboarding process - this will help you avoid unnecessary hiccups during integration.